my engine rebuild has started today

Discussion

Hi all ,hows things. I took the plunge today. As a lot of you know im doing my first engine rebuild with the help of my good friend jeff, ive been iching to to get started so jeff came round thismorning to get stuck in.

i started off cleaning the block up while i was waiting for jeff

Then timing gears and chain

jeff arrived about 10 oclock and straight away we had serious problems removing clutch plates and fly wheel, after 2 hours of trying jeff when home and got his blow torch and set to work on the clutch plate sleeve which goes over the crankshaft end.After 15mins of heating it still wouldnt budge so.......armed with a small steal bar and a lump hammer i attemted to shock the fly wheel from behind through the starter motor hole, the first wack was a good 1 but as i swung for wack number 2 i didnt notice the bar was on the cast clutch housing and....................

this made me feal sick lol, but i felt even sicker when jeff hit the clutch plate once with the hammer and it just fell off (if only id been a bit more patient jeff would have got the hammer first).

I had a brain wave and mixed up my secret formula which worked extremely well and took me about 1 hour...

not bad huh.

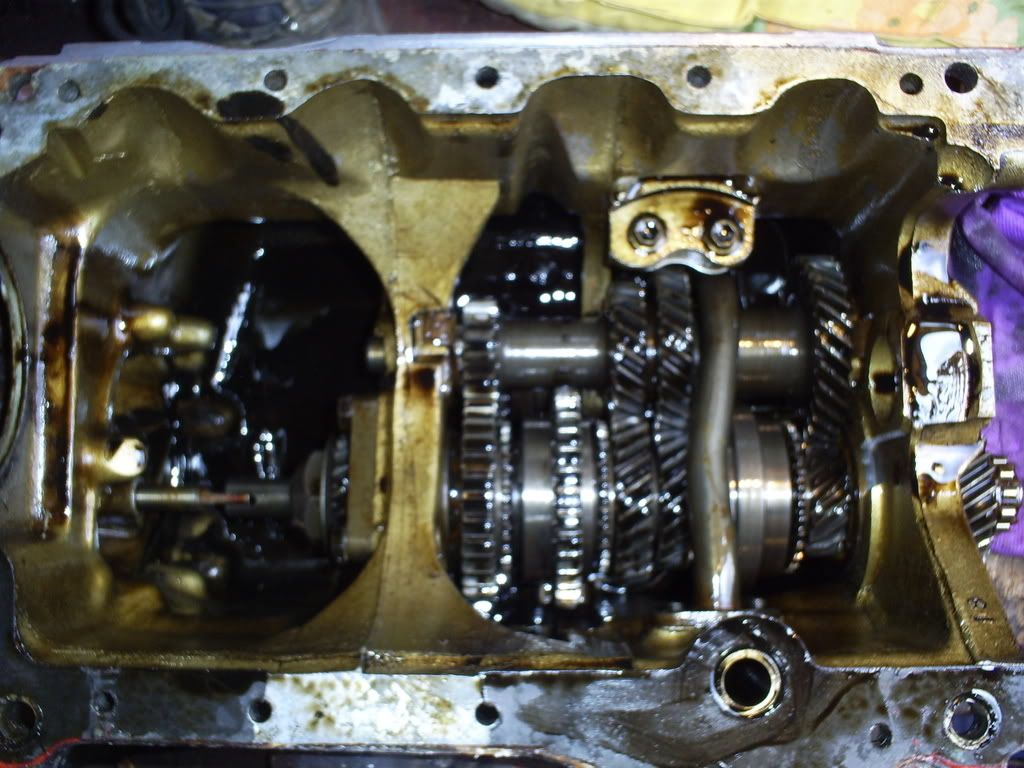

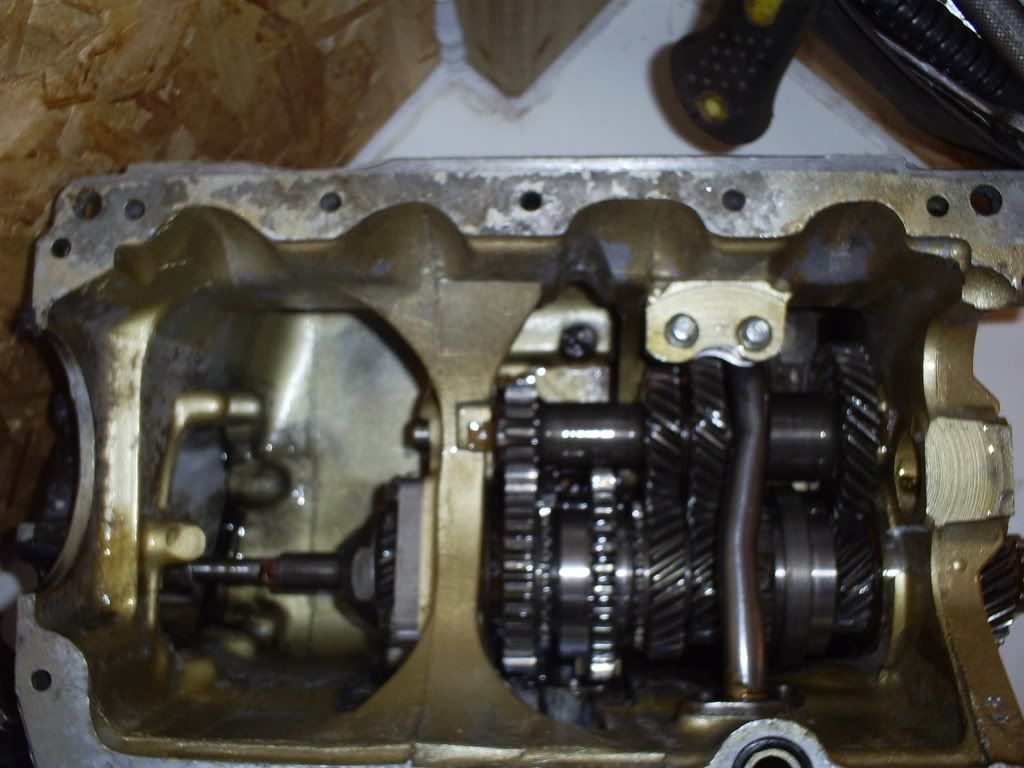

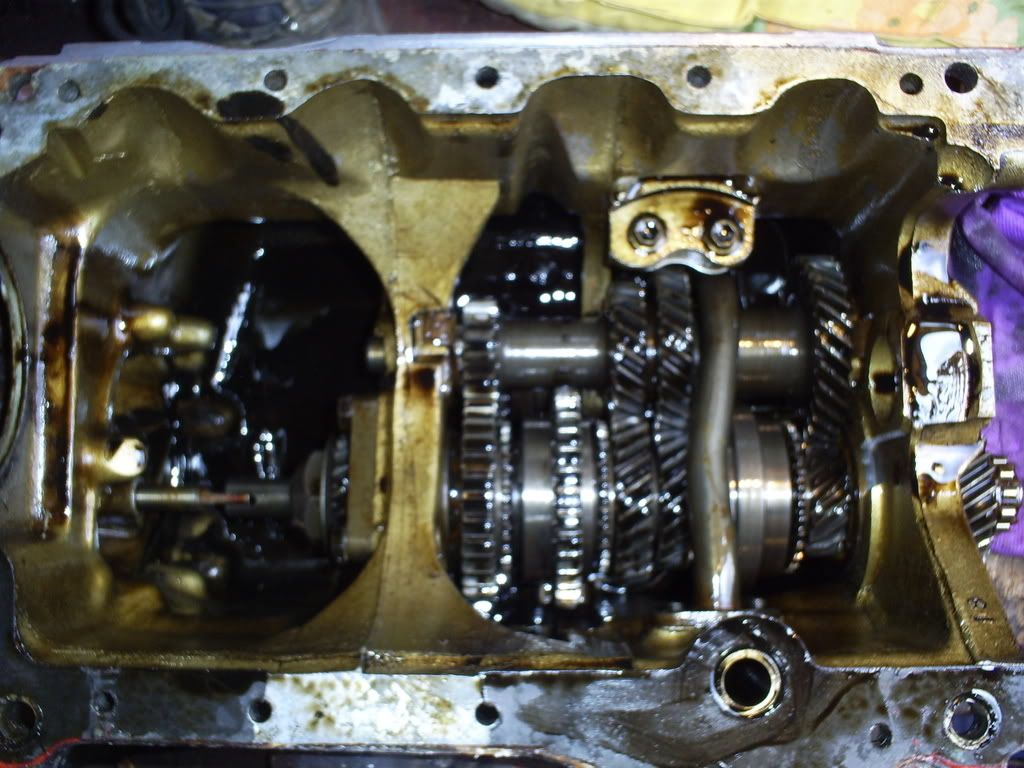

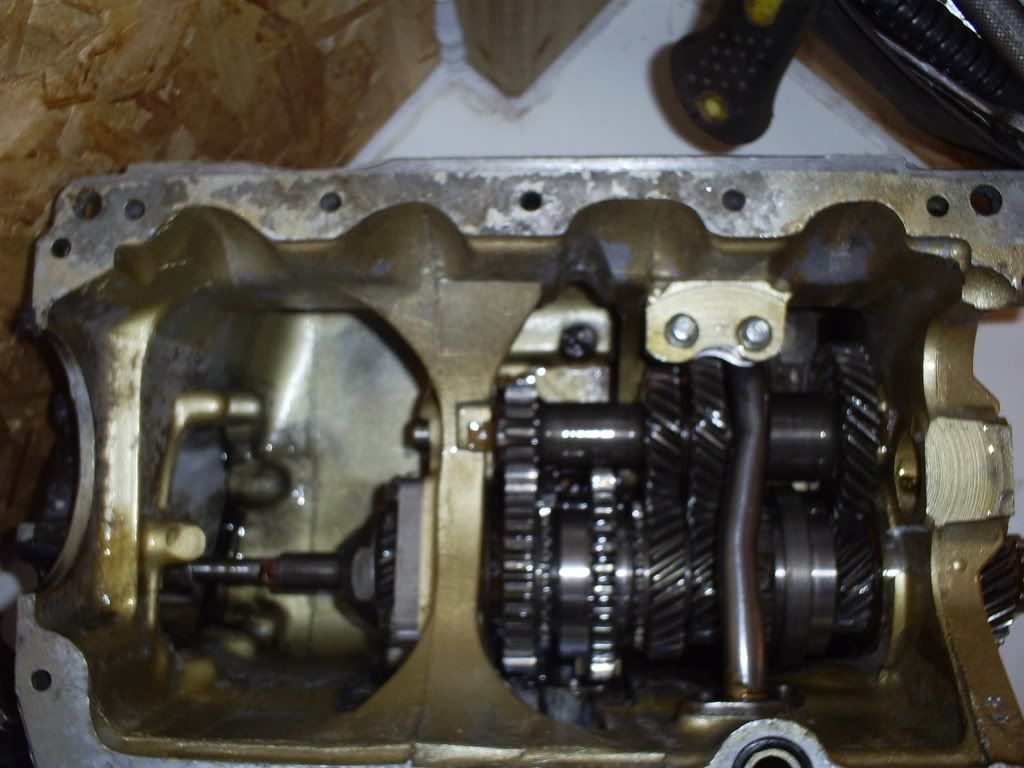

with that sorted it was on to the gear box and block strip

i have a original mk1 subframe reconditioned by myself if anyones intrested

the nxt step is to get all the bits and bobs to start putting it back together, ive decided to get a new modified and gasflowed head, expensive but worth it i think but 1 question i have is when i get the head will i have to buy the rockers, pushers , valves etc or will they come with the head, and also where is the best place to shop for a good head for reasonable price.

well thats my story for today and i hope you all enjoyed it. all the best neale.. All hints, tips and parts ideas are most welcome. cheers..

i started off cleaning the block up while i was waiting for jeff

Then timing gears and chain

jeff arrived about 10 oclock and straight away we had serious problems removing clutch plates and fly wheel, after 2 hours of trying jeff when home and got his blow torch and set to work on the clutch plate sleeve which goes over the crankshaft end.After 15mins of heating it still wouldnt budge so.......armed with a small steal bar and a lump hammer i attemted to shock the fly wheel from behind through the starter motor hole, the first wack was a good 1 but as i swung for wack number 2 i didnt notice the bar was on the cast clutch housing and....................

this made me feal sick lol, but i felt even sicker when jeff hit the clutch plate once with the hammer and it just fell off (if only id been a bit more patient jeff would have got the hammer first).

I had a brain wave and mixed up my secret formula which worked extremely well and took me about 1 hour...

not bad huh.

with that sorted it was on to the gear box and block strip

i have a original mk1 subframe reconditioned by myself if anyones intrested

the nxt step is to get all the bits and bobs to start putting it back together, ive decided to get a new modified and gasflowed head, expensive but worth it i think but 1 question i have is when i get the head will i have to buy the rockers, pushers , valves etc or will they come with the head, and also where is the best place to shop for a good head for reasonable price.

well thats my story for today and i hope you all enjoyed it. all the best neale.. All hints, tips and parts ideas are most welcome. cheers..

Edited by dogfather on Sunday 23 March 20:55

I think you have a basic digital camera with a switch or setting for taking pictures of objects or scenes, it may have a tree and a mountain symbol. It is probably set on the mountain symbol which is why the photo stood outside your workshop is better focused.

HTH

Rebuild looks like fun though, I hope to do mine one day with a Morspeed 998 sport kit etc.

Good luck with the rest.

HTH

Rebuild looks like fun though, I hope to do mine one day with a Morspeed 998 sport kit etc.

Good luck with the rest.

not the kind of tips i had in mind but your rite it duz mess up your eyes a bit, it didnt look so blurred on the cam but oh well.

"The ugly bloke" is jeff, haha cant stop chuckling to myself, cant wait to show him this thread.

"The ugly bloke" is jeff, haha cant stop chuckling to myself, cant wait to show him this thread.

phumy said:

You asked for hints or tips!!

Any chance of getting the camera to work correctly, every shot is out of focus, I thought my eyes had gone. The only one which is nearly focused is of some ugly bloke

Good luck

Any chance of getting the camera to work correctly, every shot is out of focus, I thought my eyes had gone. The only one which is nearly focused is of some ugly bloke

Good luck

you should never, ever try and remove a verto clutch (or at least not one you intend to use again!) by whacking it through the starter hole. all you will do is probably slip and damage the case (ahem!) and damage the whole assembly beyond use.

think about it, the bit you are hitting isnt directly attached to the flywheel itself, the flywheel is attached to the spring part, which in turn is attached to the crank.

this means that any impacts from a hammer are only damaging the spring portion of the clutch - really good whacks will also damage the flywheel (ive even seen people whack so hard they knock the ring gear off)

if a flywheel and spring is subjected to this abuse and is used again it will proably shake itself loose withen a few hundred miles.

this is why so many verto cars show damage to the crank taper, with the worse case been that the assemble dances so much that the bolt unwinds its self until it jams the release bearing - though once its got this far the crank and the nose piece will be shagged beyond use anyway.

id scrap that assembly and source a know good one if i where you - its just not worth the risk.

the other tip is to make sure that when you refit it to take care to get the locking key the right way round, its possible to get it 180 deg out and it look ok, then as you wind the bolt in it simply bruises the bolt threads and in turn damages the threads in the crank, in worse cases it will nip fully home and look ok - until you try and remove it again.....

i always double check the key and use a old bolt with the lock washer removed - this way there is no friction from the washer to affect the fitting. i then torque it with this bolt, have a cup of tea and come back and fit a new bolt, if its going to be a high rever (a mighty mini for example) i dab the smallest bit of locktite at the start of the bolt and fit that.

hope this makes sense

think about it, the bit you are hitting isnt directly attached to the flywheel itself, the flywheel is attached to the spring part, which in turn is attached to the crank.

this means that any impacts from a hammer are only damaging the spring portion of the clutch - really good whacks will also damage the flywheel (ive even seen people whack so hard they knock the ring gear off)

if a flywheel and spring is subjected to this abuse and is used again it will proably shake itself loose withen a few hundred miles.

this is why so many verto cars show damage to the crank taper, with the worse case been that the assemble dances so much that the bolt unwinds its self until it jams the release bearing - though once its got this far the crank and the nose piece will be shagged beyond use anyway.

id scrap that assembly and source a know good one if i where you - its just not worth the risk.

the other tip is to make sure that when you refit it to take care to get the locking key the right way round, its possible to get it 180 deg out and it look ok, then as you wind the bolt in it simply bruises the bolt threads and in turn damages the threads in the crank, in worse cases it will nip fully home and look ok - until you try and remove it again.....

i always double check the key and use a old bolt with the lock washer removed - this way there is no friction from the washer to affect the fitting. i then torque it with this bolt, have a cup of tea and come back and fit a new bolt, if its going to be a high rever (a mighty mini for example) i dab the smallest bit of locktite at the start of the bolt and fit that.

hope this makes sense

eccles said:

i know this may sound daft, but the light blue haynes book is actually very good when it comes to a step by step guide to rebuilding everything.

a couple of good hints, keep everything spotlessly clean, and invest in a good (or recently calibrated) torque wrench.

Second that, however never take their timings nor how simply it will be to be the one truth as most of the jokes around the manual come from working on cars like the mini... i.e. simply realse the pin to detach the gear rod selctor from the box. In reality it too an hour of painful prying with every tool i had, whilst on my back on a cold floor....a couple of good hints, keep everything spotlessly clean, and invest in a good (or recently calibrated) torque wrench.

Best bet is to get a guy who's done it all before (are you a member of a club?) that way they'll give you all their shortcuts without you havign to find them out for yourself.

But fialing this the manual will at least give you a good direction to head in.

Gassing Station | Classic Minis | Top of Page | What's New | My Stuff