advice on my recon head

Discussion

just after a little advice. I reconditioned the head off my spare 1300 metro engine. I bored it out a little not much thou and now im thinking of putting on my 1275 mini engine it will look great but will it provide a noticable power gain????? also i was thinking of a range rover head as these are supposed to be really good . has anyone used a range rover head and if so is it recommended or not??? thanxs...neale...

just after a little advice. I reconditioned the head off my spare 1300 metro engine. I bored it out a little not much thou and now im thinking of putting on my 1275 mini engine it will look great but will it provide a noticable power gain????? also i was thinking of a range rover head as these are supposed to be really good . has anyone used a range rover head and if so is it recommended or not??? thanxs...neale... Hi Peter,

What you haven't shown in the pics is the combustion chamber shaping and finishing. You need to modify this a bit to reduce 'valve shrouding' in order to maximise flow into the chamber. Then you should remove some of the metal from the valve guide bosses on both inlet and exhaust tracts and smooth out any lumps and bumps in the chambers themselves. Make sure you have the 35.5 mm inlet valves as some heads only have the 33.5 mm ones and that makes a difference (why, oh why, did BMC/AR/Rover make so many different head configurations when they could so easily have standardised on the 35.5 mm inlet for all 1275 engines and made our lives more simple?)

After all that you need to set the compression ratio at about 10.2:1 or slightly higher.

Do all this and you will certainly feel the difference, even with a standard cam. However, go on to fitting a Kent 266 or an MG Metro GT cam and they you'll get real power without spoiling the tractability.

I hope this helps.

Peter

What you haven't shown in the pics is the combustion chamber shaping and finishing. You need to modify this a bit to reduce 'valve shrouding' in order to maximise flow into the chamber. Then you should remove some of the metal from the valve guide bosses on both inlet and exhaust tracts and smooth out any lumps and bumps in the chambers themselves. Make sure you have the 35.5 mm inlet valves as some heads only have the 33.5 mm ones and that makes a difference (why, oh why, did BMC/AR/Rover make so many different head configurations when they could so easily have standardised on the 35.5 mm inlet for all 1275 engines and made our lives more simple?)

After all that you need to set the compression ratio at about 10.2:1 or slightly higher.

Do all this and you will certainly feel the difference, even with a standard cam. However, go on to fitting a Kent 266 or an MG Metro GT cam and they you'll get real power without spoiling the tractability.

I hope this helps.

Peter

thanks for the advice guys but the problem is, because im a bit of a noob in the miniworld the advice from cooperman went straight over my head stealth bomber style. i didnt realise that is was so technical, all those numbers confused the hell out off me so for now this kind of work is out of my league, i thought i could just slap my head on (once built) and off i go but it seems i am wrong. COOPERMAN pls egnore my question sent to you by email as i never saw your posted avice prior to sending the email. although your adice when over my head it should help the guy that puts it on for me. thanks again. neale. happy new year guys

cooperman, you've got me intreagued now!

I've got a re-con head that I did myself many years (12+?)ago which I never used. It was skimmed lightly to ensure it was true, had new valve guides put in, and I had a go at porting it myself (basically cleaning up the ports and taking the 'nibs' of the chamber - i.e. opening up the valve shrouding but only a little).

Now I have an MPi, and after reading this thread, there's no reason why I couldn't revisit this head and get a bit more out of the Cooper.

So, do you have any pictures of your combustion chambers I could compare with mine to see how much more I would need to remove? Also how do you work out your combustion ratio? I'm not sure of the valve sizes (if memory serves me well its a 295 head) but can I assume it's a relatively easy machining mod to fit the 35.5mm inlet valves (while putting in new hardened seats at the same time)?

God, why did I start reading this thread!!!

ETA, I wouldn't be looking to change the cam (I wouldn't want to take the engine out - I'll do that when the engine needs a rebuild) but would probably fit high ratio roller rockers (1:1.5?) to get a similar effect. I wouldn't want to loose the driveability of the car - it's my daily driver, but would like a bit more acceleration (and no, I don't want to change the final drive ratio, I do travel on the motorway on occasion!)

Hope if I do this I'm not taking business away from you, now you've retired cooperman!!!

I've got a re-con head that I did myself many years (12+?)ago which I never used. It was skimmed lightly to ensure it was true, had new valve guides put in, and I had a go at porting it myself (basically cleaning up the ports and taking the 'nibs' of the chamber - i.e. opening up the valve shrouding but only a little).

Now I have an MPi, and after reading this thread, there's no reason why I couldn't revisit this head and get a bit more out of the Cooper.

So, do you have any pictures of your combustion chambers I could compare with mine to see how much more I would need to remove? Also how do you work out your combustion ratio? I'm not sure of the valve sizes (if memory serves me well its a 295 head) but can I assume it's a relatively easy machining mod to fit the 35.5mm inlet valves (while putting in new hardened seats at the same time)?

God, why did I start reading this thread!!!

ETA, I wouldn't be looking to change the cam (I wouldn't want to take the engine out - I'll do that when the engine needs a rebuild) but would probably fit high ratio roller rockers (1:1.5?) to get a similar effect. I wouldn't want to loose the driveability of the car - it's my daily driver, but would like a bit more acceleration (and no, I don't want to change the final drive ratio, I do travel on the motorway on occasion!)

Hope if I do this I'm not taking business away from you, now you've retired cooperman!!!

Edited by Cooper1999 on Tuesday 8th January 12:30

Cooper1999 said:

cooperman, you've got me intreagued now!

I've got a re-con head that I did myself many years (12+?)ago which I never used. It was skimmed lightly to ensure it was true, had new valve guides put in, and I had a go at porting it myself (basically cleaning up the ports and taking the 'nibs' of the chamber - i.e. opening up the valve shrouding but only a little).

Now I have an MPi, and after reading this thread, there's no reason why I couldn't revisit this head and get a bit more out of the Cooper.

So, do you have any pictures of your combustion chambers I could compare with mine to see how much more I would need to remove? Also how do you work out your combustion ratio? I'm not sure of the valve sizes (if memory serves me well its a 295 head) but can I assume it's a relatively easy machining mod to fit the 35.5mm inlet valves (while putting in new hardened seats at the same time)?

God, why did I start reading this thread!!!

ETA, I wouldn't be looking to change the cam (I wouldn't want to take the engine out - I'll do that when the engine needs a rebuild) but would probably fit high ratio roller rockers (1:1.5?) to get a similar effect. I wouldn't want to loose the driveability of the car - it's my daily driver, but would like a bit more acceleration (and no, I don't want to change the final drive ratio, I do travel on the motorway on occasion!)

Hope if I do this I'm not taking business away from you, now you've retired cooperman!!!

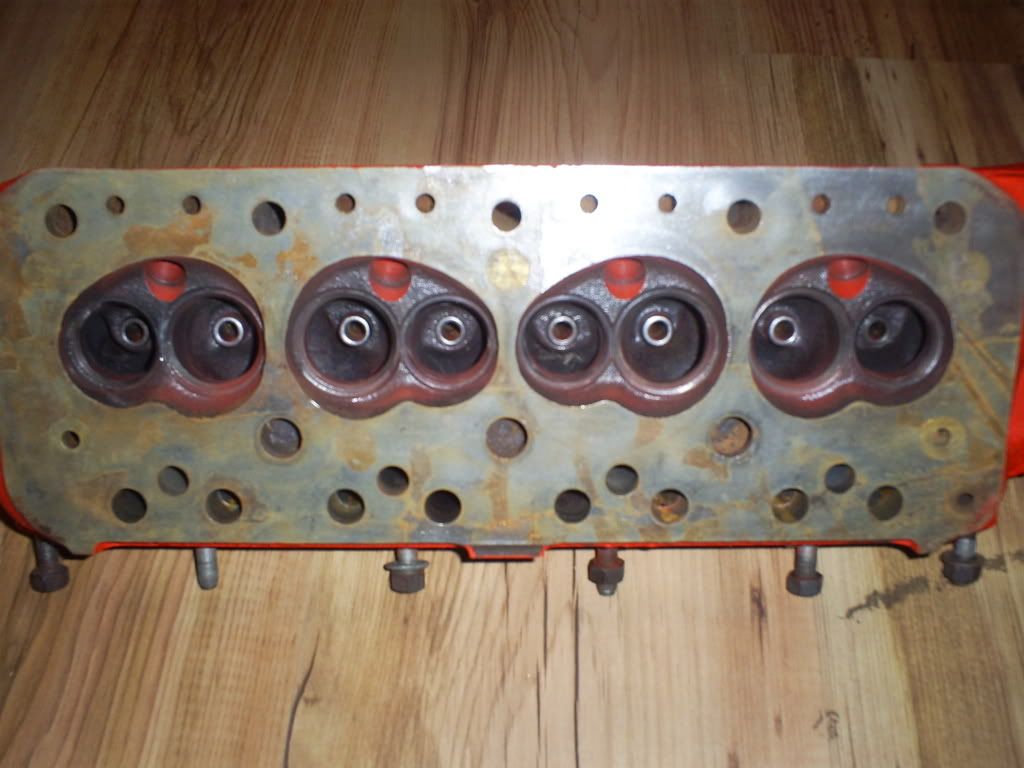

Cooper999 i know ur message was to cooperman but i thought id post a few more pics for of this head for the comparison hope it helps.I've got a re-con head that I did myself many years (12+?)ago which I never used. It was skimmed lightly to ensure it was true, had new valve guides put in, and I had a go at porting it myself (basically cleaning up the ports and taking the 'nibs' of the chamber - i.e. opening up the valve shrouding but only a little).

Now I have an MPi, and after reading this thread, there's no reason why I couldn't revisit this head and get a bit more out of the Cooper.

So, do you have any pictures of your combustion chambers I could compare with mine to see how much more I would need to remove? Also how do you work out your combustion ratio? I'm not sure of the valve sizes (if memory serves me well its a 295 head) but can I assume it's a relatively easy machining mod to fit the 35.5mm inlet valves (while putting in new hardened seats at the same time)?

God, why did I start reading this thread!!!

ETA, I wouldn't be looking to change the cam (I wouldn't want to take the engine out - I'll do that when the engine needs a rebuild) but would probably fit high ratio roller rockers (1:1.5?) to get a similar effect. I wouldn't want to loose the driveability of the car - it's my daily driver, but would like a bit more acceleration (and no, I don't want to change the final drive ratio, I do travel on the motorway on occasion!)

Hope if I do this I'm not taking business away from you, now you've retired cooperman!!!

Edited by Cooper1999 on Tuesday 8th January 12:30

dogfather, many thanks. From the pictures I can see I still need to take much more material away from the 'nib' between the valves (opposite the plug hole where it intrudes into the chamber to prevent the mixture from scooting straight out of the exhaust valve, if that makes sense?).

What sort of spec is this head - fast road, rally, race? This would give me an idea of how much to take away.

How do the people who do lots of heads ensure each chamber / port is flowing the same (I don't have access to a flow meter) or is it a case of what looks right, is right?

How do you measure the compression ratio (the head has had a light skim, but my car is a daily driver and I would want to continue using 95RON unleaded).

So many questions - but thanks for your time!

What sort of spec is this head - fast road, rally, race? This would give me an idea of how much to take away.

How do the people who do lots of heads ensure each chamber / port is flowing the same (I don't have access to a flow meter) or is it a case of what looks right, is right?

How do you measure the compression ratio (the head has had a light skim, but my car is a daily driver and I would want to continue using 95RON unleaded).

So many questions - but thanks for your time!

Cooper1999 said:

dogfather, many thanks. From the pictures I can see I still need to take much more material away from the 'nib' between the valves (opposite the plug hole where it intrudes into the chamber to prevent the mixture from scooting straight out of the exhaust valve, if that makes sense?).

What sort of spec is this head - fast road, rally, race?

Looks like a bog standard 12G940. The chambers haven't been modified anyway and it doesn't look like the ports have been touched. Largish valves, so possibly from an MG Metro or 1275 auto?What sort of spec is this head - fast road, rally, race?

Mr2Mike, I'm doing this from memory but as I remember the head I have looks different from this, in the area of the chamber that I described. I do remember it having quite a clear casting mark on it detailing the type of head - I'll have to dig it out this weekend and confirm all of this.

Do you port your own heads?

Do you port your own heads?

Mr2Mike said:

Cooper1999 said:

dogfather, many thanks. From the pictures I can see I still need to take much more material away from the 'nib' between the valves (opposite the plug hole where it intrudes into the chamber to prevent the mixture from scooting straight out of the exhaust valve, if that makes sense?).

What sort of spec is this head - fast road, rally, race?

Looks like a bog standard 12G940. The chambers haven't been modified anyway and it doesn't look like the ports have been touched. Largish valves, so possibly from an MG Metro or 1275 auto?What sort of spec is this head - fast road, rally, race?

i also found a great mini garage in birmingham just down from the 6ways island in erdington if anyone is interested, many years of mini experience including restoration, rolling road tuning,mini meet days where he gets as many minis on the rollers as he can in the day.He issues certificates for best mini in each engine class on the day and has very very reasonable prices ie £45per hr on the rollers and only £55 for 2 hrs, 10 or more cars £15 each for a 15-20min session he also sells all kinds of mini accesories, wheels/tyres, services and mots (i think he does mots but not 100percent)www.collinsmotoringservices.com . i spoke to him lastnite on the phone he seems a really nice bloke.

i hope this helps somone out like it has me. thanks..neale..

Edited by dogfather on Wednesday 9th January 20:43

Dug the head out at the weekend (and realised its nearer 15 years since I played with it!). I was staggered at the good condition of it - its been double wrapped in black plastic bags since then!

A very technical measuring of the valve seats (holding a plastic ruler over the combustion chamber!) showed the valve sizes to be around 28mm inlet/24mm exhaust. Does anyone know if this is the 998cc sizes? That would make sense as I had a 998cc at the time. So I think it'll be best to invest in a1275cc head and start again! Oh, and invest in a copy of Vizards book from Amazon too! (Does it cover any specific needs of the MPi mini?)

Here's a pic anyway:

A very technical measuring of the valve seats (holding a plastic ruler over the combustion chamber!) showed the valve sizes to be around 28mm inlet/24mm exhaust. Does anyone know if this is the 998cc sizes? That would make sense as I had a 998cc at the time. So I think it'll be best to invest in a1275cc head and start again! Oh, and invest in a copy of Vizards book from Amazon too! (Does it cover any specific needs of the MPi mini?)

Here's a pic anyway:

[quote=Cooper1999]Dug the head out at the weekend (and realised its nearer 15 years since I played with it!). I was staggered at the good condition of it - its been double wrapped in black plastic bags since then!

A very technical measuring of the valve seats (holding a plastic ruler over the combustion chamber!) showed the valve sizes to be around 28mm inlet/24mm exhaust. Does anyone know if this is the 998cc sizes? That would make sense as I had a 998cc at the time. So I think it'll be best to invest in a1275cc head and start again! Oh, and invest in a copy of Vizards book from Amazon too! (Does it cover any specific needs of the MPi mini?)

Here's a pic anyway:

i measuered mine using the same method and i know this is a 1300cc they were 30mm inlet/25mm exhaust hope this helps, but ill check for you now to see what yours came off

A very technical measuring of the valve seats (holding a plastic ruler over the combustion chamber!) showed the valve sizes to be around 28mm inlet/24mm exhaust. Does anyone know if this is the 998cc sizes? That would make sense as I had a 998cc at the time. So I think it'll be best to invest in a1275cc head and start again! Oh, and invest in a copy of Vizards book from Amazon too! (Does it cover any specific needs of the MPi mini?)

Here's a pic anyway:

i measuered mine using the same method and i know this is a 1300cc they were 30mm inlet/25mm exhaust hope this helps, but ill check for you now to see what yours came off

Sorry I've not replied to this thread sooner but I had a complete hard disk failure and have only just got my machine back.

The problem with valve sizes is that even some of the accepted books have got the sizes wrong and BMC/BLMC/Rover haven't helped over the years.

For example, if you look in the Haynes Manual it tells you that a 1990-ish Cooper 1275 had 35.5mm inlets, whereas the ones I've seen have all been 33.5mm. True the MG Metro 1275's all had 35.5mm inlets and the heads are interchangeable.

When you look at the surface finish inside the combustion chambers in the photos it's just amazing how rough the surfaces are.

I have to go out now, but I'll come back on this, probably tomorrow, if you think I can help at all.

Peter

The problem with valve sizes is that even some of the accepted books have got the sizes wrong and BMC/BLMC/Rover haven't helped over the years.

For example, if you look in the Haynes Manual it tells you that a 1990-ish Cooper 1275 had 35.5mm inlets, whereas the ones I've seen have all been 33.5mm. True the MG Metro 1275's all had 35.5mm inlets and the heads are interchangeable.

When you look at the surface finish inside the combustion chambers in the photos it's just amazing how rough the surfaces are.

I have to go out now, but I'll come back on this, probably tomorrow, if you think I can help at all.

Peter

Cooperman, I most definitely think you can help - I get the impression from your threads you may have done this once or twice in the past.....

I ordered the Vizard book yesterday, so I should be able to glean some info from that, but there no substitute for experience!

From heads I've bought in the past I can appreachiate your comments on the chamber finish - what tools do you polish / shape your heads with? (I'm limited to using an electric drill, so as I remember head work does take a while...).

On a personnal note, any comments appropriate to an MPi head would be appreciated.

Cheers.

I ordered the Vizard book yesterday, so I should be able to glean some info from that, but there no substitute for experience!

From heads I've bought in the past I can appreachiate your comments on the chamber finish - what tools do you polish / shape your heads with? (I'm limited to using an electric drill, so as I remember head work does take a while...).

On a personnal note, any comments appropriate to an MPi head would be appreciated.

Cheers.

Hi Cooper 1999.

Sorry I've not replied sooner but the day after I finally got back on-line, all the phones in the village went down due to the local floods here (on the edge of the Fens) and when BT repaired the fault they connected two villages up the 'wrong way round' (yes, really, it was on Anglia TV last night). We are finally back on today so I was really not ignoring you.

If you can, it's best to use a really good selection of grinding bits with an air-driven die-grinder. Electric drills are a bit too slow and the grinding bits tend to judder too much.

For the initial shaping and blending I always leave the old scrap valves in to avoid damaging the seats, but if you are intending to fit bigger inlet valves it not such a problem. With Mini heads being so well established, you actually don't need a flow bench unless you want the ultimate race power. Vizard's book really does give you all you need to know about shapes and sizes. It's just having the confidence to do it that counts. I always remember how nervous I used to be about 30 years ago when I first started doing my own heads. You don't need a highly polished finish. A good flap-wheel finish is fine. The expensive heads with almost mirror-finish surfaces cost a lot, but don't perform any better. It's the shaping that matter in order for the mixture to flow in as well as possible.

After you have shaped the chambers and lapped in the valves, check the chamber volumes with either a shringe of a burette. However, there is a lot of rubbish talked about this as, in practice, it's hard to know when the chamber is full of paraffin, water, petrol, or whatever liquid you decide to use. All you can do is to use your best judgement and get the volumes as equual as possible. That's what I do and it seems to work for me.

Feel free to personal email me if I can be of any more help. If you want I will give you my phone number or, if you live near enough to Cambridge, you could call round sometime and bring the head with you.

I hope this helps,

Peter

Sorry I've not replied sooner but the day after I finally got back on-line, all the phones in the village went down due to the local floods here (on the edge of the Fens) and when BT repaired the fault they connected two villages up the 'wrong way round' (yes, really, it was on Anglia TV last night). We are finally back on today so I was really not ignoring you.

If you can, it's best to use a really good selection of grinding bits with an air-driven die-grinder. Electric drills are a bit too slow and the grinding bits tend to judder too much.

For the initial shaping and blending I always leave the old scrap valves in to avoid damaging the seats, but if you are intending to fit bigger inlet valves it not such a problem. With Mini heads being so well established, you actually don't need a flow bench unless you want the ultimate race power. Vizard's book really does give you all you need to know about shapes and sizes. It's just having the confidence to do it that counts. I always remember how nervous I used to be about 30 years ago when I first started doing my own heads. You don't need a highly polished finish. A good flap-wheel finish is fine. The expensive heads with almost mirror-finish surfaces cost a lot, but don't perform any better. It's the shaping that matter in order for the mixture to flow in as well as possible.

After you have shaped the chambers and lapped in the valves, check the chamber volumes with either a shringe of a burette. However, there is a lot of rubbish talked about this as, in practice, it's hard to know when the chamber is full of paraffin, water, petrol, or whatever liquid you decide to use. All you can do is to use your best judgement and get the volumes as equual as possible. That's what I do and it seems to work for me.

Feel free to personal email me if I can be of any more help. If you want I will give you my phone number or, if you live near enough to Cambridge, you could call round sometime and bring the head with you.

I hope this helps,

Peter

i thought to measure chamber sizes you lightly silicone (or similiar) a piece of glass over the chambers with a couple of holes above each chamber. measure how much fluid is needed to fill to the holes in each chamber. this will give you a good measurement, make sure your valves are siliconed in aswell!

I have tried that in the past using a piece of perspex, but I still find the results a bit less that ideal. What I do is to fit the valves, check for leaks around the valves, fill each chamber in turn to what seems an identical level, then increase the capacity of any chamber which is a bit too small. In practice if you pay attention to the chamber re-shaping, you get pretty close anyway, so not much additional grinding is needed. I always reckon that + or -about 0.5 cc is OK for most applications and you can get that close with experience and judgement when filling each chamber.

Gassing Station | Classic Minis | Top of Page | What's New | My Stuff