Recommendations For Online Metal CNC Companies

Discussion

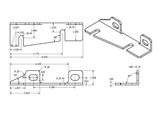

I'm looking to have a couple of small (200 mm x 75 mm x 5 mm) steel brackets fabricated as per image below. I have the designs available in DXF and DWG formats.

I assume that these would be ideally suited for a CNC machine, although happy to hear other fabrication options that may be more appropriate and cost effective for a one-off project. Otherwise can anyone recommend an online CNC machining or metal fabrication service that handles small jobs?

I assume that these would be ideally suited for a CNC machine, although happy to hear other fabrication options that may be more appropriate and cost effective for a one-off project. Otherwise can anyone recommend an online CNC machining or metal fabrication service that handles small jobs?

Edited by EViS on Sunday 20th July 17:00

Red Rocket Engineering will sort you out.

https://www.redrocketengineering.com/

Not an affiliation of me by the way. Just someone who has done work for me.

https://www.redrocketengineering.com/

Not an affiliation of me by the way. Just someone who has done work for me.

EViS said:

I'm looking to have a couple of small (200 mm x 75 mm x 5 mm) steel brackets fabricated as per image below. I have the designs available in DXF and DWG formats.

I assume that these would be ideally suited for a CNC machine, although happy to hear other fabrication options that may be more appropriate and cost effective for a one-off project. Otherwise can anyone recommend an online CNC machining or metal fabrication service that handles small jobs?

Either that's one very small bracket or you've drawn it in imperial.I assume that these would be ideally suited for a CNC machine, although happy to hear other fabrication options that may be more appropriate and cost effective for a one-off project. Otherwise can anyone recommend an online CNC machining or metal fabrication service that handles small jobs?

Edited by EViS on Sunday 20th July 17:00

You've dimensioned that to three decimal places but not specified a tolerance

.188 of an inch is 4.77mm but to get the 2.557 dimension you'd have to use stock 70mm X 70mm X 6mm angle with all the ball ache of taking the 6mm down to 4.77mm and keeping it square.

Find someone with a laser cutter and a press brake accepting that you can't have it made to three decimal places, the PH'er 'Seabod91' might be able to help?

Tango13 said:

Either that's one very small bracket or you've drawn it in imperial.

You've dimensioned that to three decimal places but not specified a tolerance

.188 of an inch is 4.77mm but to get the 2.557 dimension you'd have to use stock 70mm X 70mm X 6mm angle with all the ball ache of taking the 6mm down to 4.77mm and keeping it square.

Find someone with a laser cutter and a press brake accepting that you can't have it made to three decimal places, the PH'er 'Seabod91' might be able to help?

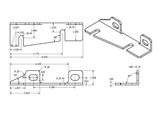

This is an imperial part drawn in inches. I can amend all the dims to metric (mm), as per attachment. Additionally, the plate thickness does not need to be exactly 4.77 mm nor does the outside corner radius need to be exactly 6.35 mm or 7.62 mm.You've dimensioned that to three decimal places but not specified a tolerance

.188 of an inch is 4.77mm but to get the 2.557 dimension you'd have to use stock 70mm X 70mm X 6mm angle with all the ball ache of taking the 6mm down to 4.77mm and keeping it square.

Find someone with a laser cutter and a press brake accepting that you can't have it made to three decimal places, the PH'er 'Seabod91' might be able to help?

Before drawing something, understand how it is to be made.

A lot of dimensions on there, how many of them matter?

I've had things made, with lots of tight dimensions like that, and they've cost hundreds of pounds, which was fine in the context.

Equally, I've needed a bracket and got some steel angle drilled and milled for a few quid.

And scrounged a bit of metal and done the job with a drill a saw and a file.

A lot of dimensions on there, how many of them matter?

I've had things made, with lots of tight dimensions like that, and they've cost hundreds of pounds, which was fine in the context.

Equally, I've needed a bracket and got some steel angle drilled and milled for a few quid.

And scrounged a bit of metal and done the job with a drill a saw and a file.

OutInTheShed said:

Before drawing something, understand how it is to be made.

A lot of dimensions on there, how many of them matter?

I've had things made, with lots of tight dimensions like that, and they've cost hundreds of pounds, which was fine in the context.

Equally, I've needed a bracket and got some steel angle drilled and milled for a few quid.

And scrounged a bit of metal and done the job with a drill a saw and a file.

Fair point noted, thanks. There are a fair few dims and angles there that are far from important, nor is the plate thickness (to the nearest mm!).A lot of dimensions on there, how many of them matter?

I've had things made, with lots of tight dimensions like that, and they've cost hundreds of pounds, which was fine in the context.

Equally, I've needed a bracket and got some steel angle drilled and milled for a few quid.

And scrounged a bit of metal and done the job with a drill a saw and a file.

Which of the details matter and which are just there because it's drawn that way? Radiuses/thicknesses/angles/relative positions?

Could you simplify it, either as a folded part or by assuming it was made from angle? What is the bare minimum you need?

As mentioned - tolerances/units/rounding.

I know back in the day I drew up parts that were duly delivered and they could have been much simpler & cheaper if I'd stuck to the critical information and skipped some of the 'simple' detail specs that didn't matter functionally but someone had to meet anyway.

Could you simplify it, either as a folded part or by assuming it was made from angle? What is the bare minimum you need?

As mentioned - tolerances/units/rounding.

I know back in the day I drew up parts that were duly delivered and they could have been much simpler & cheaper if I'd stuck to the critical information and skipped some of the 'simple' detail specs that didn't matter functionally but someone had to meet anyway.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff