How the Dutch do it

Discussion

I read something a while ago, which I can’t really remember, and may also not even be correct. Because internet.

It was something to do with I think in the Netherlands, how they pipe their systems better than us. And I’m sure it was that they use separate manifolds for flow and return to rads. I suppose like WUFH. You can then use TRV at the rads, or on each ‘zone’. This also may not be correct. But it also somewhat reduces the requirement for balancing. That is probably definitely not correct.

If this is anywhere near the truth, then the re-pipe of my current 8mm microbore system may be totally DIYable. And far less complex than our ‘branch’ systems. Especially if PEX pipe is used, and is surely reliable given there are far fewer joints. And if the manifold is easily accessed.

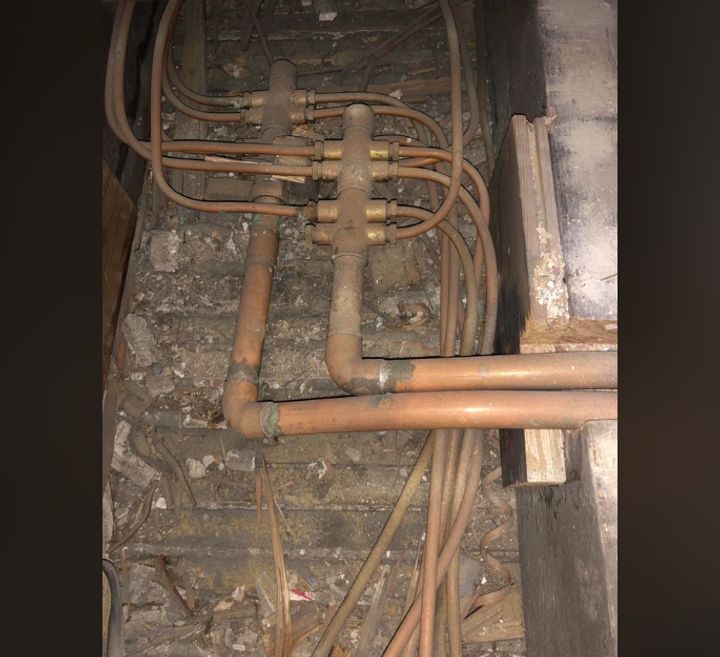

I believe the existing late 70’s system may also use a manifold! Will likely look like this.

Cheers!

It was something to do with I think in the Netherlands, how they pipe their systems better than us. And I’m sure it was that they use separate manifolds for flow and return to rads. I suppose like WUFH. You can then use TRV at the rads, or on each ‘zone’. This also may not be correct. But it also somewhat reduces the requirement for balancing. That is probably definitely not correct.

If this is anywhere near the truth, then the re-pipe of my current 8mm microbore system may be totally DIYable. And far less complex than our ‘branch’ systems. Especially if PEX pipe is used, and is surely reliable given there are far fewer joints. And if the manifold is easily accessed.

I believe the existing late 70’s system may also use a manifold! Will likely look like this.

Edited by PT1984 on Wednesday 19th March 16:37

Cheers!

Edited by PT1984 on Wednesday 19th March 16:56

I have got Manifolds in my house, when changing the boiler, radiators and re-plumbing the whole house, the plumber ( my uncle) suggested manifolds.

Ive got one for the upstairs for flow and return and one for the downstairs, flow and return.

It's ran in 22mm from the boiler to the manifolds which then drop down to 10mm which is man enough to do all but the biggest rads.

https://www.screwfix.com/p/hep2o-plastic-push-fit-...

It also keeps joints to a minimum and in one place if a leak does happen.

Ive got one for the upstairs for flow and return and one for the downstairs, flow and return.

It's ran in 22mm from the boiler to the manifolds which then drop down to 10mm which is man enough to do all but the biggest rads.

https://www.screwfix.com/p/hep2o-plastic-push-fit-...

It also keeps joints to a minimum and in one place if a leak does happen.

PT1984 said:

So who is right? I find they tend to do most things better over the channel.

I’m not a fluid engineer. But a manifold certainly makes sense. Assuming most tails are of equal length.

Would it be that the British system was designed to use less pipework, at a time when copper was expensive - the same principle as ring mains versus spurs for wiring.I’m not a fluid engineer. But a manifold certainly makes sense. Assuming most tails are of equal length.

Edited by PT1984 on Wednesday 19th March 19:52

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff