Clutch slipping issue/reconsideration needed?

Discussion

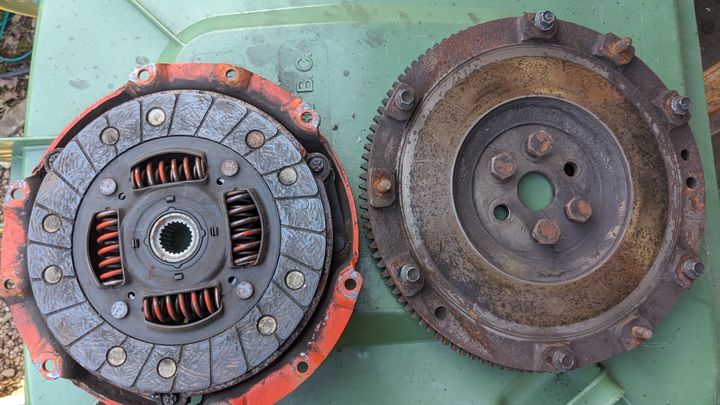

So during an engine swap I have been working on I upgraded the clutch to match the power of the engine.

I got the flywheel resurfaced as a precaution before fitting the new clutch, however I am having a few issues where when coming off the clutch and holding it under light conditions I can feel it catching unevenly, I thought I needed it in correctly and after about 100 miles on the clutch did do a half throttle pull and noticed it slipped under the power.

Dut to other issues with the engine (possible timing chain issue so have re-done this) I have had to take it out the engine, whilst doing this I have also took the clutch off.

As a home mechanic and not a professional I am wondering a couple of things. First what might of caused this? And with the pictures attached is there anything I need to do to recondition this clutch?

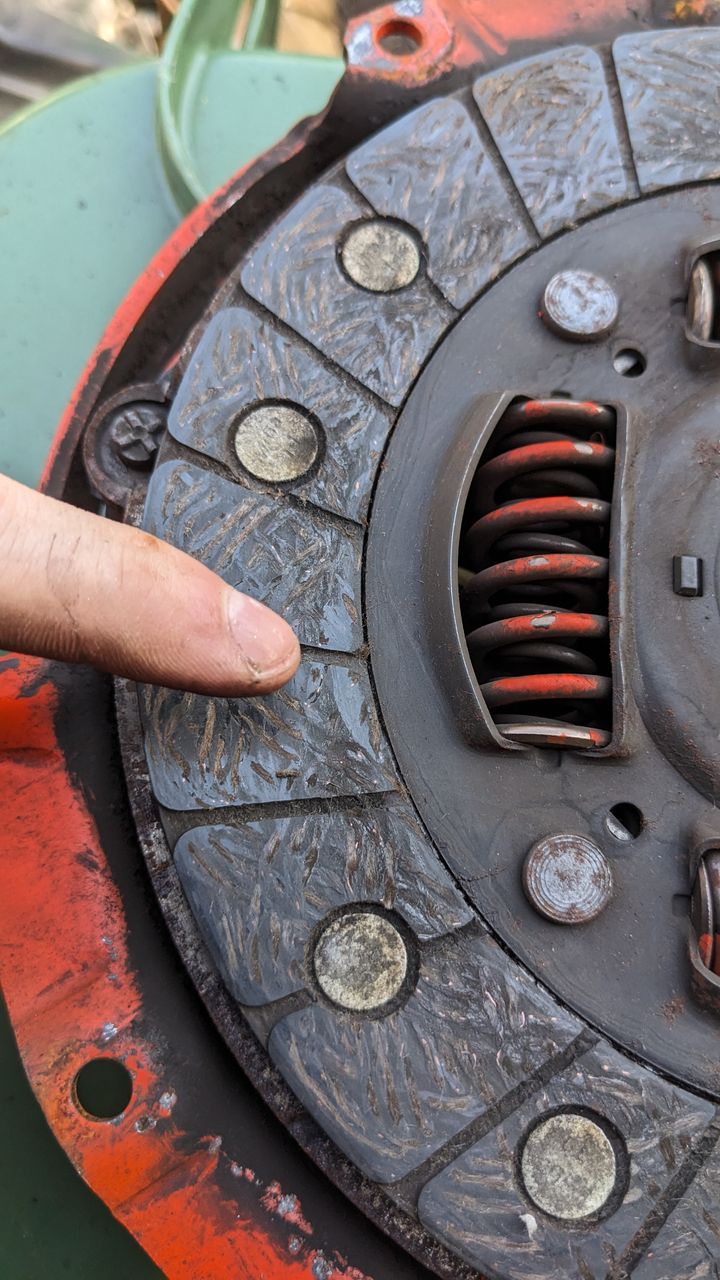

I have read if it's glazed to rub it down a little but for the most part, to me at least, looks fine. I have noticed a small area on the clutch that has seemed to ware away a little bit and have a separate picture pointing to it.

On the back side I have noticed a small heat area at 3 points forming though, have put a picture of that too.

Any help would be most appreciated!

I got the flywheel resurfaced as a precaution before fitting the new clutch, however I am having a few issues where when coming off the clutch and holding it under light conditions I can feel it catching unevenly, I thought I needed it in correctly and after about 100 miles on the clutch did do a half throttle pull and noticed it slipped under the power.

Dut to other issues with the engine (possible timing chain issue so have re-done this) I have had to take it out the engine, whilst doing this I have also took the clutch off.

As a home mechanic and not a professional I am wondering a couple of things. First what might of caused this? And with the pictures attached is there anything I need to do to recondition this clutch?

I have read if it's glazed to rub it down a little but for the most part, to me at least, looks fine. I have noticed a small area on the clutch that has seemed to ware away a little bit and have a separate picture pointing to it.

On the back side I have noticed a small heat area at 3 points forming though, have put a picture of that too.

Any help would be most appreciated!

Something looks very odd about that flywheel, the contact surface with the clutch disc is heavily contaminated. When you say it was "resurfaced" - what did they do? Normally it would either be okay as-is (and you'd give it a decent clean) or you'd skim it and it should look like shiny metal.

Just for the sake of completeness, how is your engine's rear main seal; and the gearbox's input shaft seal? With a new-ish clutch disc and a resurfaced flywheel, I'd expect it to be much cleaner and no slipping. I am wondering if that's oil contamination from one or both of the aforementioned seals leaking (quite a lot).

element118 said:

I got it machined/skimmed, it was completely shiny when I had it back but had kept it out of the car for a while and had got surface rust by the time I had put back in, but I cleaned that up before I put it back in

That's more than surface rust - that's fairly serious corrosion which is probably the root of the problem.Edited by element118 on Saturday 8th March 19:36

Rally appreciate the feedback!

To answer some questions, the gear box seal is fine, the gearbox was off the original car, had no issues with that, same as the flywheel, this was also off my original car (mx5 MK3 1.8) and was clean when I took it off that, got it skimmed as I was putting this performance clutch on, brand new from bofi racing, so I'm assuming the pressure plate was flat. With that said it was in good condition when it was skimmed and really didn't need much taking off at all.

This project has been on and off for almost 2 years, I got the flywheel skimmed fairly early in the project alongside getting the clutch.

I had left it on my boot for a while, by the time I took it out it had got corrosion on it, so cleaned it up, lightly sanding it evenly back a little.

The only thing to note, and this is probably/possibly where my in experience is, there is a small gap between the block and the gearbox housing, my presumption at the time, as the engine that I swapped in uses the same block that the original engine also used, that this was by design.

So when I say a small gap, it's probably about 2cm long by a couple of mm wide, might not even be that big, it might also meet up internally where I can't see, but also could be a possible location for contamination ingress, or where rust could of continued (200 miles in 2 years means it hasn't had much use).

So going of recommendations here,

1st get the flywheel sorted.

2nd check to see if the pressure plate is flat (I'm assuming using an engineers straight edge?)

If it's not, can this be machined like a flywheel?

3rd Check the engine main seal, I have had the engine out and didn't notice anything leaking but will triple check it.

To answer some questions, the gear box seal is fine, the gearbox was off the original car, had no issues with that, same as the flywheel, this was also off my original car (mx5 MK3 1.8) and was clean when I took it off that, got it skimmed as I was putting this performance clutch on, brand new from bofi racing, so I'm assuming the pressure plate was flat. With that said it was in good condition when it was skimmed and really didn't need much taking off at all.

This project has been on and off for almost 2 years, I got the flywheel skimmed fairly early in the project alongside getting the clutch.

I had left it on my boot for a while, by the time I took it out it had got corrosion on it, so cleaned it up, lightly sanding it evenly back a little.

The only thing to note, and this is probably/possibly where my in experience is, there is a small gap between the block and the gearbox housing, my presumption at the time, as the engine that I swapped in uses the same block that the original engine also used, that this was by design.

So when I say a small gap, it's probably about 2cm long by a couple of mm wide, might not even be that big, it might also meet up internally where I can't see, but also could be a possible location for contamination ingress, or where rust could of continued (200 miles in 2 years means it hasn't had much use).

So going of recommendations here,

1st get the flywheel sorted.

2nd check to see if the pressure plate is flat (I'm assuming using an engineers straight edge?)

If it's not, can this be machined like a flywheel?

3rd Check the engine main seal, I have had the engine out and didn't notice anything leaking but will triple check it.

Gassing Station | Home Mechanics | Top of Page | What's New | My Stuff