500+bhp Lotus Elise S2 with Quaife Sequential Gearbox

Discussion

Hi all,

A friend advised me to get a pistonheads thread of my car build going. I am quite far into to build/rebuild already but I will try to bring you all up to date while keeping this as short as I can.

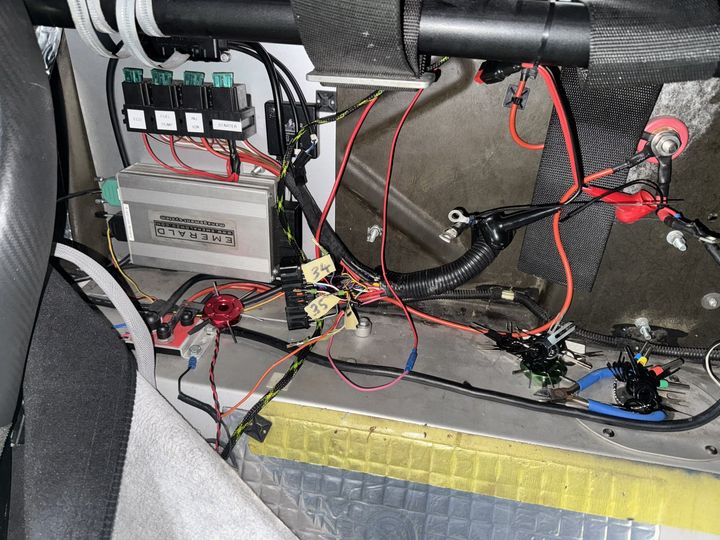

It's a 2002 Lotus Elise, which had a 1.8T Audi S3 engine fitted around the year 2005. It had been thoroughly enjoyed and developed by the previous owners over the years and then I bought the car in October 2024. Its basic specs were fully forged and 320bhp, Emerald ECU, Nitron 46 shocks, forged cup wheels etc.

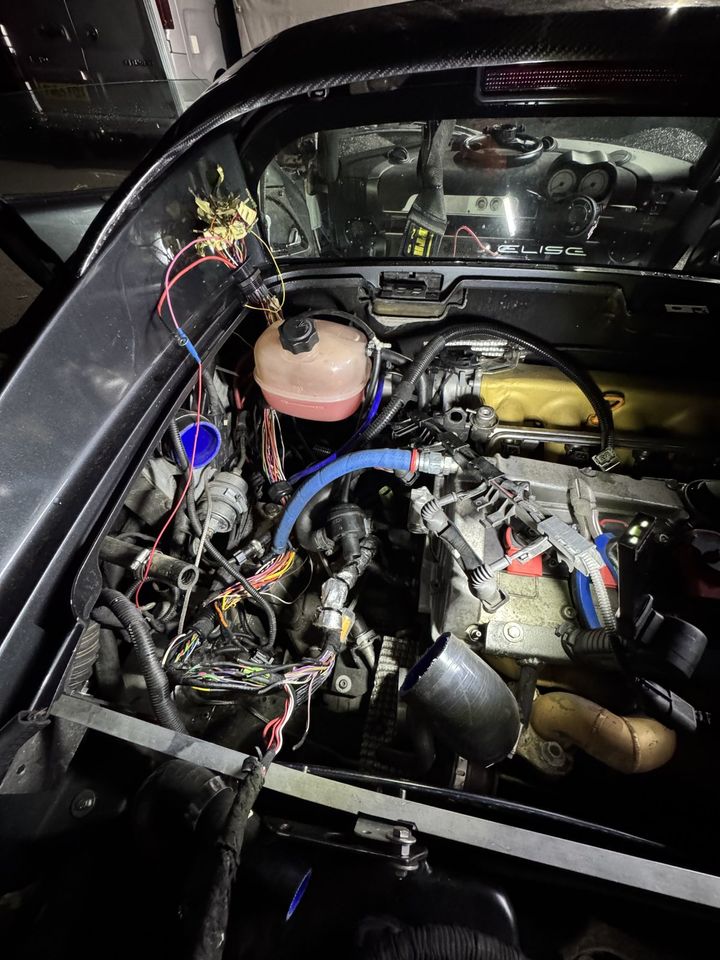

Long story short, it arrived to me on 30th October and by 31st October, its engine seized. I bought the car from a dealer under the impression that the car was sorted and it wasn't. Without getting into it, we came to a deal and I was somewhat compensated then I started figuring the direction in which I wanted to move forward with it. On inspection of the engine prior to its removal, the rear torque mount, which functions to prevent the engine from rocking under its own power, wasn't bolted in. Consequently on my first drive, the engine rocked forwards and a bolt holding the lower wishbone in place, punched a hole in the sump and it drained itself of oil. YAY....

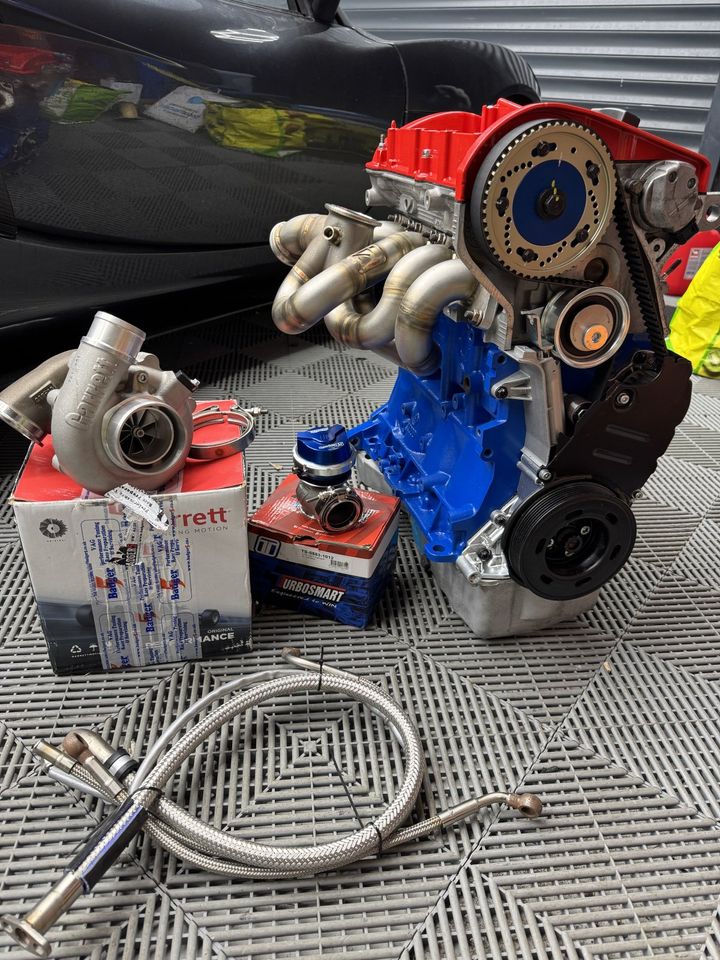

I considered various engine options, including the common K20/K24 route but having a history of some extremely fast cars, the NA engines weren't going to do it for me. I was then looking at a boosted K20 but given the cost/effort in doing so, I saw marginal gains over a very high spec version of the engine that was already in the car. So, I purchased a race-spec built engine by the renowned 1.8T tuner; Badger5 and decided to right all the wrongs on this build, hoping to build something truly special (and reliable)

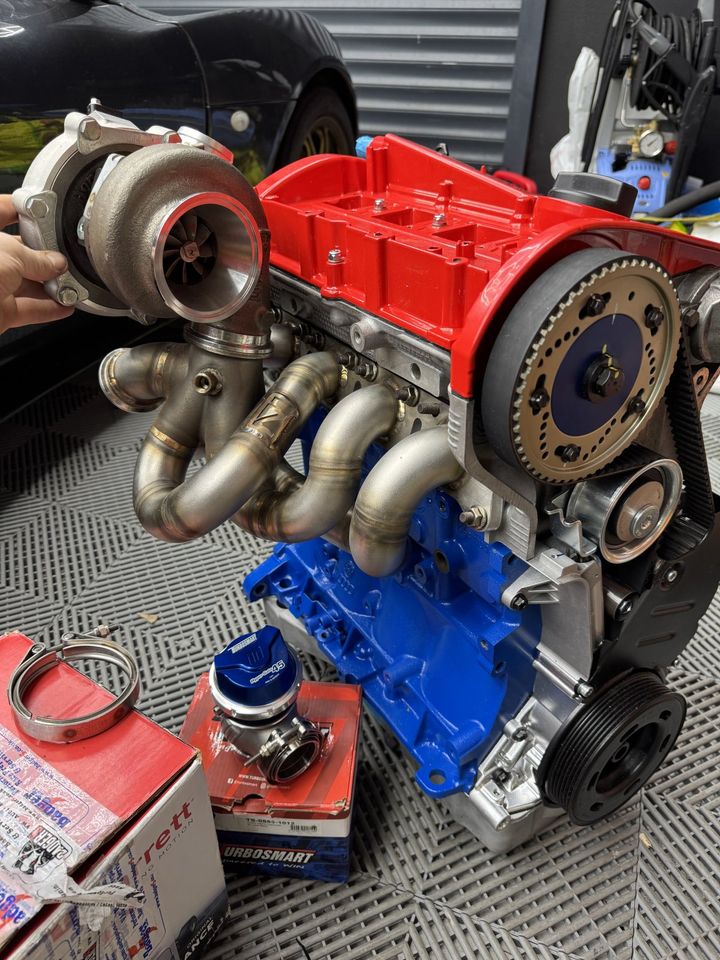

For anyone that’s interested, here’s the full spec of the engine:

-- 82.5mm bore, 9.5:1 compression

- Catcams performance cams (Badger5 spec)

- Catcams vernier pulley

- Supertech inlet and exhaust valves

- Supertech valvesprings

- Supertech retainers

- ARP cam bolt

- I-Beam rifle drilled forged rods (144x20)

- ARP 2000 bolts

- JE Forged pistons

- ARP Mainstuds

- ARP Headstuds

- ARP crank bolt

- Fluidampr harmonic balancer

- Billet steel crank main caps

- Gates belt kit & tensioner

- OE Water pump

- OE Oil pump & pickup pipe

- ACL Race bigend and main bearings

- KS Thrust bearings

- Elring head gasket

- Baffled sump

- Garrett G25-660 turbo

- Nortech tubular manifold

- Turbosmart Hypergate45 external wastegate

- acid & caustic dipped & hotwashed, cleaned blocks, core plugs removed, rebored

- dynamically balanced & polished crank journals

- precision end to end balanced rods & pistons

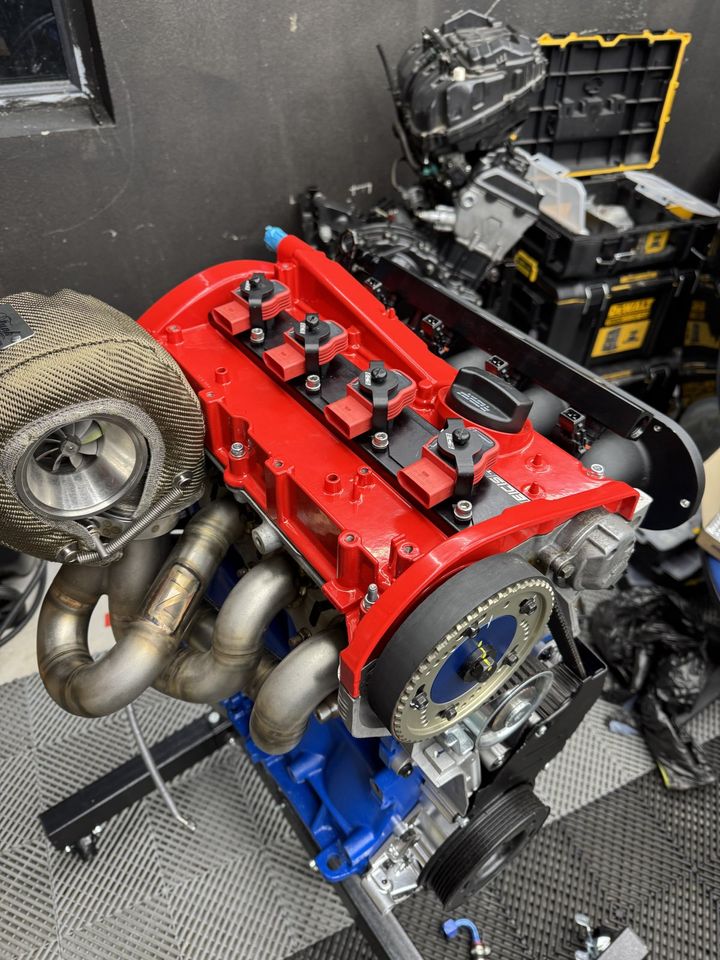

- painted block, and powder coated rocker covers

As a matter of priority on this build, I had the engine 3D scanned so we could properly fabricate a STRONG engine torque mount. This will prevent any 'rocking' going forward.

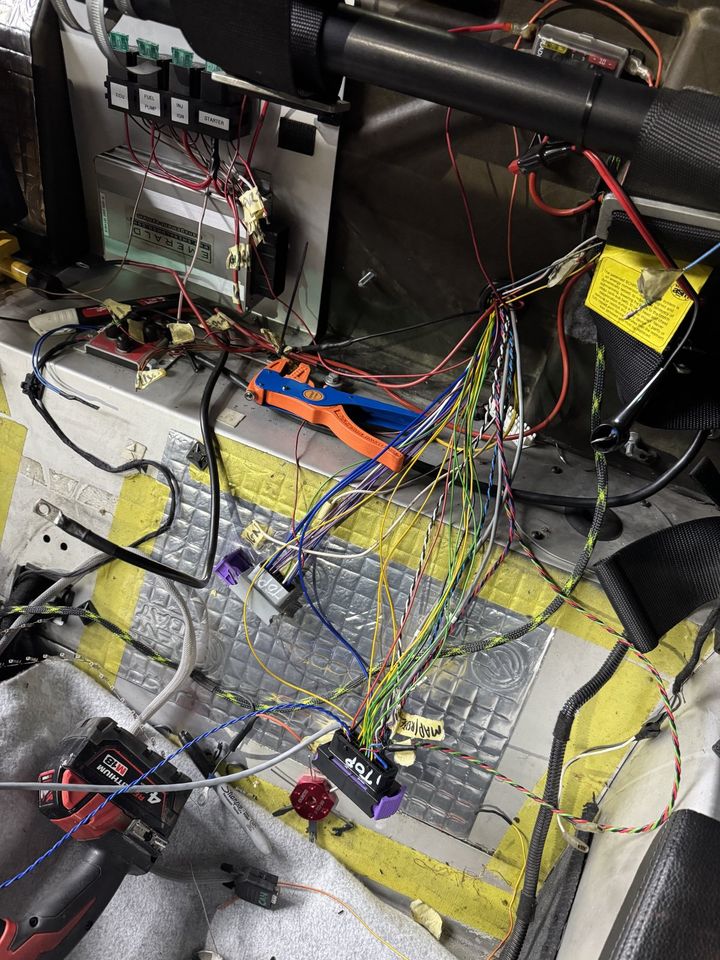

I pulled the entire wiring loom out of the car and decided I wanted it redone as it was a complete birds nest. The old Emerald ECU wasn't fit for any of the modern tech I wanted to run, so I opted for an ECU Master Black with V3 software for closed loop flatshift control etc, GPS-CAN module for speedo/lap-timer etc, a CANBUS keypad for controlling all of the car's functions and an 'ADU5' digital dash display to get rid of the archaic stack dash. I am not a mechanic or electrician, but I have been building cars as a hobbyist over the years, so I do almost everything on this build myself with the exception of the fabrication. I am friends with an exceptional fabricator, so I am a firm believer in letting him do that side of things! All of the wiring was done by myself, using Raychem DR25 sheathing and brand new automotive connectors, so the loom should stand the test of time. I also converted the car from cable throttle to drive-by-wire, utilizing a pedal potentiometer from a BMW E39 and an electronic throttle body from a Mk5 Golf R32.

I then ordered a Quaife sequential gearbox and despite having some issues by way of multiple cracked donor bellhousings, I eventually received the freshly-built Quaife at the end of January. To fit the gearbox, I had it 3D scanned so a CAD designed, custom-fabricated shifter cable bracket could be made to secure the cable to the box to suit this RWD transverse application (the Quaife box only has a casted mount to suit FWD application so could not be used).

I have started to get into YouTube for my own benefit of having something to look back on, so I will probably continue this thread by uploading videos of the cars progress. However, the pics to follow will bring you up to date with where I am at with the car. I am planning to press the start button tomorrow and at least crank the car over, generating oil pressure/testing for leaks etc. So we are not far away!

If anyone wants to stay up to date, my YouTube link is https://www.youtube.com/@Carkevo

A friend advised me to get a pistonheads thread of my car build going. I am quite far into to build/rebuild already but I will try to bring you all up to date while keeping this as short as I can.

It's a 2002 Lotus Elise, which had a 1.8T Audi S3 engine fitted around the year 2005. It had been thoroughly enjoyed and developed by the previous owners over the years and then I bought the car in October 2024. Its basic specs were fully forged and 320bhp, Emerald ECU, Nitron 46 shocks, forged cup wheels etc.

Long story short, it arrived to me on 30th October and by 31st October, its engine seized. I bought the car from a dealer under the impression that the car was sorted and it wasn't. Without getting into it, we came to a deal and I was somewhat compensated then I started figuring the direction in which I wanted to move forward with it. On inspection of the engine prior to its removal, the rear torque mount, which functions to prevent the engine from rocking under its own power, wasn't bolted in. Consequently on my first drive, the engine rocked forwards and a bolt holding the lower wishbone in place, punched a hole in the sump and it drained itself of oil. YAY....

I considered various engine options, including the common K20/K24 route but having a history of some extremely fast cars, the NA engines weren't going to do it for me. I was then looking at a boosted K20 but given the cost/effort in doing so, I saw marginal gains over a very high spec version of the engine that was already in the car. So, I purchased a race-spec built engine by the renowned 1.8T tuner; Badger5 and decided to right all the wrongs on this build, hoping to build something truly special (and reliable)

For anyone that’s interested, here’s the full spec of the engine:

-- 82.5mm bore, 9.5:1 compression

- Catcams performance cams (Badger5 spec)

- Catcams vernier pulley

- Supertech inlet and exhaust valves

- Supertech valvesprings

- Supertech retainers

- ARP cam bolt

- I-Beam rifle drilled forged rods (144x20)

- ARP 2000 bolts

- JE Forged pistons

- ARP Mainstuds

- ARP Headstuds

- ARP crank bolt

- Fluidampr harmonic balancer

- Billet steel crank main caps

- Gates belt kit & tensioner

- OE Water pump

- OE Oil pump & pickup pipe

- ACL Race bigend and main bearings

- KS Thrust bearings

- Elring head gasket

- Baffled sump

- Garrett G25-660 turbo

- Nortech tubular manifold

- Turbosmart Hypergate45 external wastegate

- acid & caustic dipped & hotwashed, cleaned blocks, core plugs removed, rebored

- dynamically balanced & polished crank journals

- precision end to end balanced rods & pistons

- painted block, and powder coated rocker covers

As a matter of priority on this build, I had the engine 3D scanned so we could properly fabricate a STRONG engine torque mount. This will prevent any 'rocking' going forward.

I pulled the entire wiring loom out of the car and decided I wanted it redone as it was a complete birds nest. The old Emerald ECU wasn't fit for any of the modern tech I wanted to run, so I opted for an ECU Master Black with V3 software for closed loop flatshift control etc, GPS-CAN module for speedo/lap-timer etc, a CANBUS keypad for controlling all of the car's functions and an 'ADU5' digital dash display to get rid of the archaic stack dash. I am not a mechanic or electrician, but I have been building cars as a hobbyist over the years, so I do almost everything on this build myself with the exception of the fabrication. I am friends with an exceptional fabricator, so I am a firm believer in letting him do that side of things! All of the wiring was done by myself, using Raychem DR25 sheathing and brand new automotive connectors, so the loom should stand the test of time. I also converted the car from cable throttle to drive-by-wire, utilizing a pedal potentiometer from a BMW E39 and an electronic throttle body from a Mk5 Golf R32.

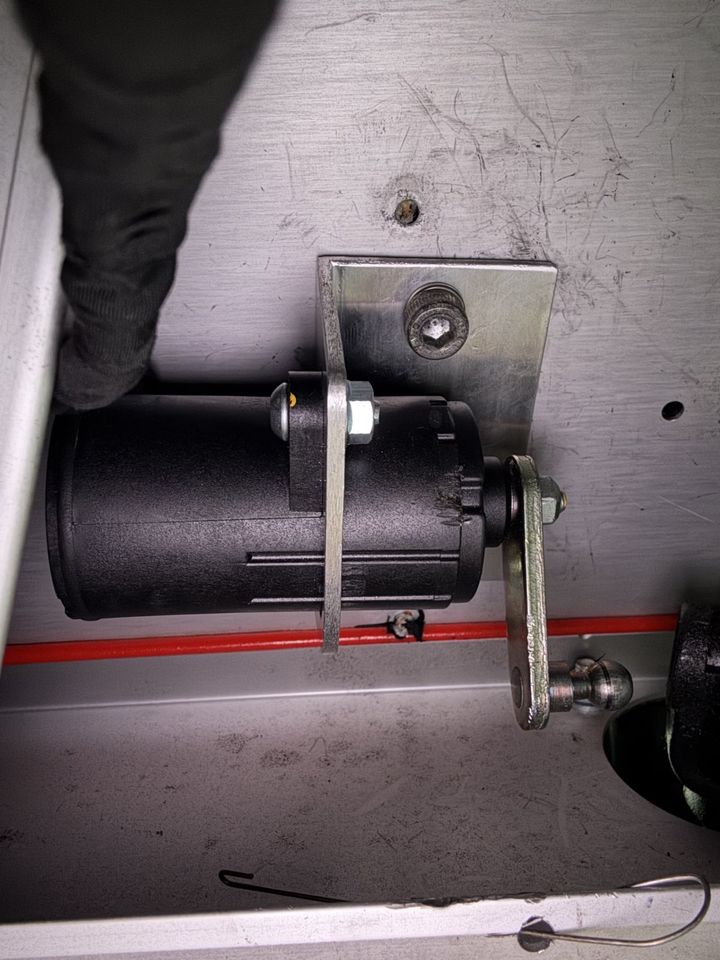

I then ordered a Quaife sequential gearbox and despite having some issues by way of multiple cracked donor bellhousings, I eventually received the freshly-built Quaife at the end of January. To fit the gearbox, I had it 3D scanned so a CAD designed, custom-fabricated shifter cable bracket could be made to secure the cable to the box to suit this RWD transverse application (the Quaife box only has a casted mount to suit FWD application so could not be used).

I have started to get into YouTube for my own benefit of having something to look back on, so I will probably continue this thread by uploading videos of the cars progress. However, the pics to follow will bring you up to date with where I am at with the car. I am planning to press the start button tomorrow and at least crank the car over, generating oil pressure/testing for leaks etc. So we are not far away!

If anyone wants to stay up to date, my YouTube link is https://www.youtube.com/@Carkevo

Edited by Carkevo on Friday 7th March 10:34

Edited by Carkevo on Friday 7th March 10:49

Edited by Carkevo on Friday 7th March 10:50

Edited by Carkevo on Friday 7th March 10:53

Looking forward to following this, thanks for taking the time to document it. (I'll subscribe to your Youtube channel when I get home from work as well).

Can I assume that you'll be doing plenty of track days when this is complete?

I can barely stretch my Exige 410's legs on the road, so god knows what this will feel like once done!

Can I assume that you'll be doing plenty of track days when this is complete?

I can barely stretch my Exige 410's legs on the road, so god knows what this will feel like once done!

Thanks Paul!

Yes, I intend on doing as many Irish/UK track days as possible and providing I have a requisite level of reliability, Spa/Ring days too.

I’ll probably just update YouTube going forward and post the links in here as it’s much easier for me recording a video and just dropping it on the thread.

Be nice to see your Exige 410! Considered one but a nice fresh Exige doesn’t want to see me tinkering hands! 😂

Yes, I intend on doing as many Irish/UK track days as possible and providing I have a requisite level of reliability, Spa/Ring days too.

I’ll probably just update YouTube going forward and post the links in here as it’s much easier for me recording a video and just dropping it on the thread.

Be nice to see your Exige 410! Considered one but a nice fresh Exige doesn’t want to see me tinkering hands! 😂

Carkevo said:

Thanks Paul!

Yes, I intend on doing as many Irish/UK track days as possible and providing I have a requisite level of reliability, Spa/Ring days too.

I’ll probably just update YouTube going forward and post the links in here as it’s much easier for me recording a video and just dropping it on the thread.

Be nice to see your Exige 410! Considered one but a nice fresh Exige doesn’t want to see me tinkering hands! ??

You'll be having a blast in that, and probably chasing race teams rather than other track dayers.Yes, I intend on doing as many Irish/UK track days as possible and providing I have a requisite level of reliability, Spa/Ring days too.

I’ll probably just update YouTube going forward and post the links in here as it’s much easier for me recording a video and just dropping it on the thread.

Be nice to see your Exige 410! Considered one but a nice fresh Exige doesn’t want to see me tinkering hands! ??

I did a thread about a my adventures with my Exige, but it certainly doesn't involve anything like yours. Changing brake pads was about as complicated as mine got

https://www.pistonheads.com/gassing/topic.asp?h=0&...

It’s been a long two days sitting in the driver seat, on the laptop changing ECU settings but we got there!

Here we are, she breathes. Very smoky as it’s burning off excess oil etc

https://youtu.be/NvFhzcFM1KY?si=wk3LDozoYptcyLlo

Here we are, she breathes. Very smoky as it’s burning off excess oil etc

https://youtu.be/NvFhzcFM1KY?si=wk3LDozoYptcyLlo

Edited by Carkevo on Sunday 9th March 20:57

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff

t start to ownership but thats the risk when taking on someone else’s project.

t start to ownership but thats the risk when taking on someone else’s project.