Front Wheel arch liners

Discussion

Does anyone have suggestions on how to reform the shape of them?

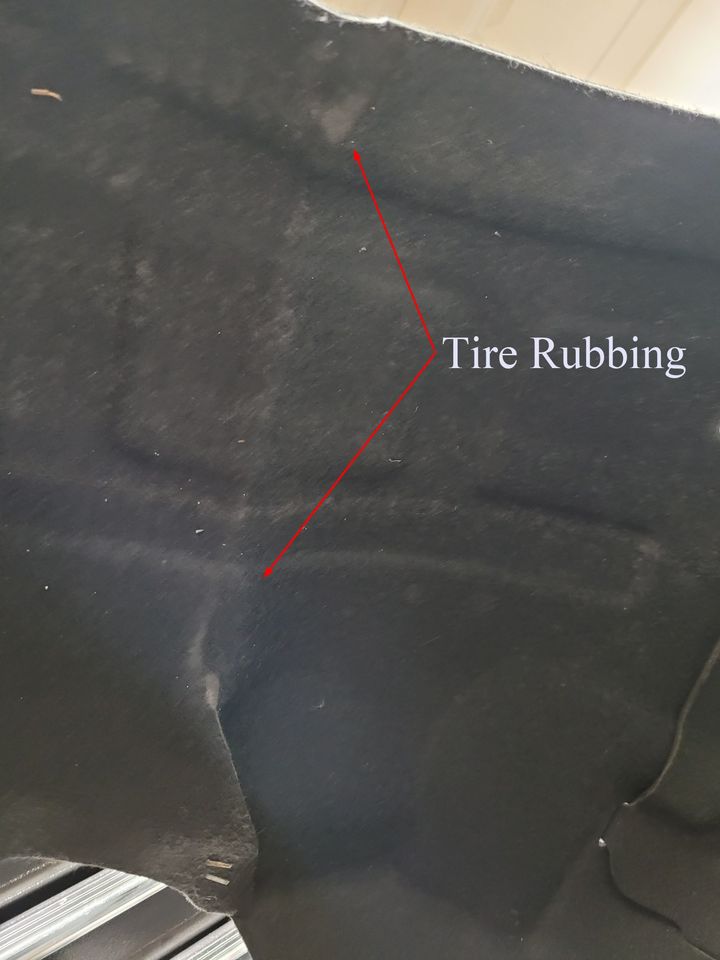

My DB9.2 has some cupping happening on the top section; so when installed it is starting to cup downward enough that you can see the underside of the liner when looking into the wheel well.

It's a section about 3" wide, outside and on the inside. The underside of the cupping is also starting to rub on the tire a bit.

My DB9.2 has some cupping happening on the top section; so when installed it is starting to cup downward enough that you can see the underside of the liner when looking into the wheel well.

It's a section about 3" wide, outside and on the inside. The underside of the cupping is also starting to rub on the tire a bit.

Not sure what plastic material they are made of but this will be an important factor, e.g. is it thermosetting or thermoplastic as thermosetting would be harder brittle and not possible to be reformed or reshaped with heat.

If thermoplastic, which I believe they must be, I’d imagine it needs heat to be applied to warm and allow reshaping then you’d need to strengthen and re-enforce the areas where it is deforming, by adding and bonding plastic strips and possibly even metal strips for support.

But I’d reach out to folks in the AMOC club section for your car to find tried and tested solutions.

If thermoplastic, which I believe they must be, I’d imagine it needs heat to be applied to warm and allow reshaping then you’d need to strengthen and re-enforce the areas where it is deforming, by adding and bonding plastic strips and possibly even metal strips for support.

But I’d reach out to folks in the AMOC club section for your car to find tried and tested solutions.

Edited by Apollya on Wednesday 22 January 12:39

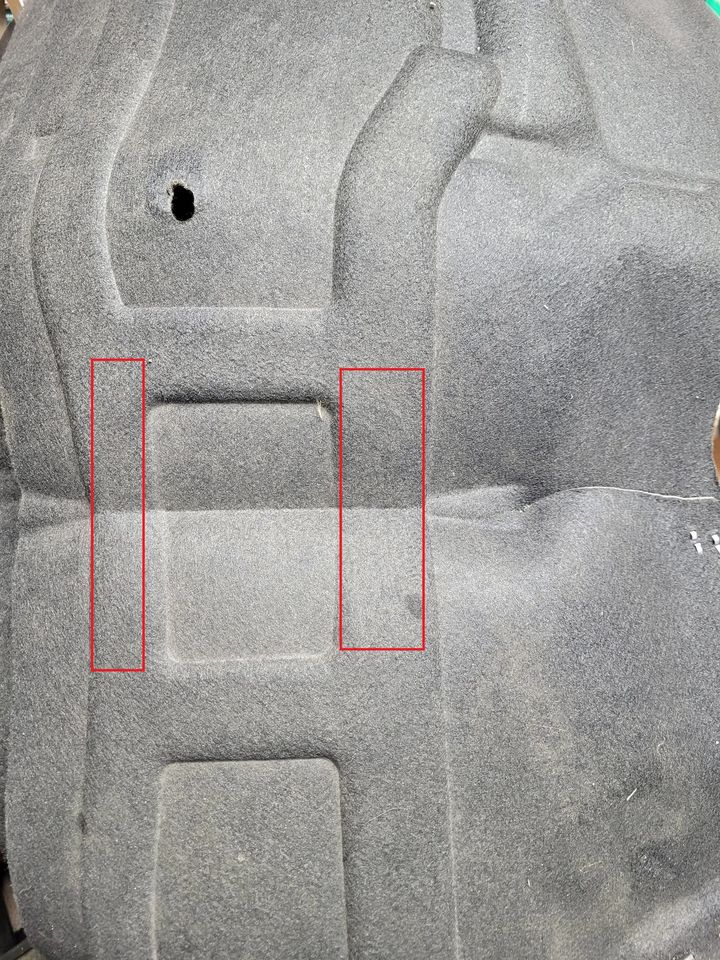

My $0.02 is that liner does not look like the hard plastic type that they fitted to the Vantages, but is more of a fibrous mat or felt-like material, probably to reduce the noise of gravel rattle and to save weight.

If I'm right, one of the problem with these materials is once they crease they get a "memory", a bit like folding a piece of paper - you can flatten it but it will always fold easily along the new fold line. Another issue with some of these man-made fibrous mat materials is if you try to bond to them you often just bond to the surface layer, which can then be pulled off and delaminate the mat underneath it.

If I were in your position, and depending on the clearance above the liner when installed, I'd be looking to reinforce the material with something like pieces of aluminium sheet on the top surface both bonded on with fibreglass and pop-riveted through, with either large washers or even another sheet of aluminium on the underside to sandwich the liner and make it hold its shape. Probably two flat strips on the raised sections on the opposite side to what looks like reinforcing depressions.

If the form is flat enough and there is sufficient clearance you could even use angle or box section for extra rigidity

If I'm right, one of the problem with these materials is once they crease they get a "memory", a bit like folding a piece of paper - you can flatten it but it will always fold easily along the new fold line. Another issue with some of these man-made fibrous mat materials is if you try to bond to them you often just bond to the surface layer, which can then be pulled off and delaminate the mat underneath it.

If I were in your position, and depending on the clearance above the liner when installed, I'd be looking to reinforce the material with something like pieces of aluminium sheet on the top surface both bonded on with fibreglass and pop-riveted through, with either large washers or even another sheet of aluminium on the underside to sandwich the liner and make it hold its shape. Probably two flat strips on the raised sections on the opposite side to what looks like reinforcing depressions.

If the form is flat enough and there is sufficient clearance you could even use angle or box section for extra rigidity

From the pictures it would seem that the affected area is a crease.

How did it get creased? Maybe when replacing the air filters?

As, has been mentioned, various materials act in different ways when heated or bonded.

LTP mentioned reinforcement using a variety of materials, which would be my way out.

I only have experience of early DB9 liners and they seem to be pretty tuff (and appear to be of a different material and shape to that shown in the photo) and they do have a considerable amount of sound deadening material attached to the inside of the liner.

Flexibility is the key to fully or part removing the liner, so whatever method you choose the need retain that flexibility is important, maybe not so much if you carry out maintenance yourself , but definitely so, if garage serviced.

You realistically have two methods of repair, chemical or mechanical reinforcement as I can’t see reshaping with heat alone will satisfactorily resolve this situation.

If you go down the pop rivet reinforcement route then a flexible material that is strong enough to support the area and not permanently distort should be used and it should be as long as is practicable so as to spread the load, otherwise the liner will probably crease again adjacent to the original failure when being removed.

If this does not work you could try fiber glassing over the area.

How did it get creased? Maybe when replacing the air filters?

As, has been mentioned, various materials act in different ways when heated or bonded.

LTP mentioned reinforcement using a variety of materials, which would be my way out.

I only have experience of early DB9 liners and they seem to be pretty tuff (and appear to be of a different material and shape to that shown in the photo) and they do have a considerable amount of sound deadening material attached to the inside of the liner.

Flexibility is the key to fully or part removing the liner, so whatever method you choose the need retain that flexibility is important, maybe not so much if you carry out maintenance yourself , but definitely so, if garage serviced.

You realistically have two methods of repair, chemical or mechanical reinforcement as I can’t see reshaping with heat alone will satisfactorily resolve this situation.

If you go down the pop rivet reinforcement route then a flexible material that is strong enough to support the area and not permanently distort should be used and it should be as long as is practicable so as to spread the load, otherwise the liner will probably crease again adjacent to the original failure when being removed.

If this does not work you could try fiber glassing over the area.

LTP said:

My $0.02 is that liner does not look like the hard plastic type that they fitted to the Vantages, but is more of a fibrous mat or felt-like material, probably to reduce the noise of gravel rattle and to save weight.

You are correct, they are the fibrous/felt mat style.Mine were already creased from previous owner(s)/mechanics. I mean these things are around 6ft (2M) long so i can see them being somewhat easy to crease along the tops like mine are.

I like the idea of using aluminum strips for reinforcement as you pointed out, and I think the use of large head pop-rivets could work quite well.

I could see fiberglass separating from this material fairly easily. You can see that the factory used industrial staples where the material is overlapped instead of a bonding agent.

Thanks for everyone's input.

Edited by AM-DB9 on Thursday 23 January 00:39

Gassing Station | Aston Martin | Top of Page | What's New | My Stuff