Extending joists. Which method?

Discussion

Removing a staircase and need to extend 4 joists from approx 1.5 meters and adding to 1.8 meters to make approx 3.3 meter joists. Can’t remove old joists so need to be extended. Two methods I’m considering and I’ll do whichever is considered best practice. Joist will cement bedded into brick pocket on internal cavity wall. Joist are 8 x 2 and all plates and extensions would be in 8 x 2

Edited by Mad Maximus on Friday 29th November 12:17

You’re looking at more than doubling the clear span without increasing the dimensions of the joist or adding any additional support?

You’d have to be quite lucky for that to work, irrespective of how you join them.

Have you looked at any span tables to see what size you should be using and how it compares to what is already there?

You’d have to be quite lucky for that to work, irrespective of how you join them.

Have you looked at any span tables to see what size you should be using and how it compares to what is already there?

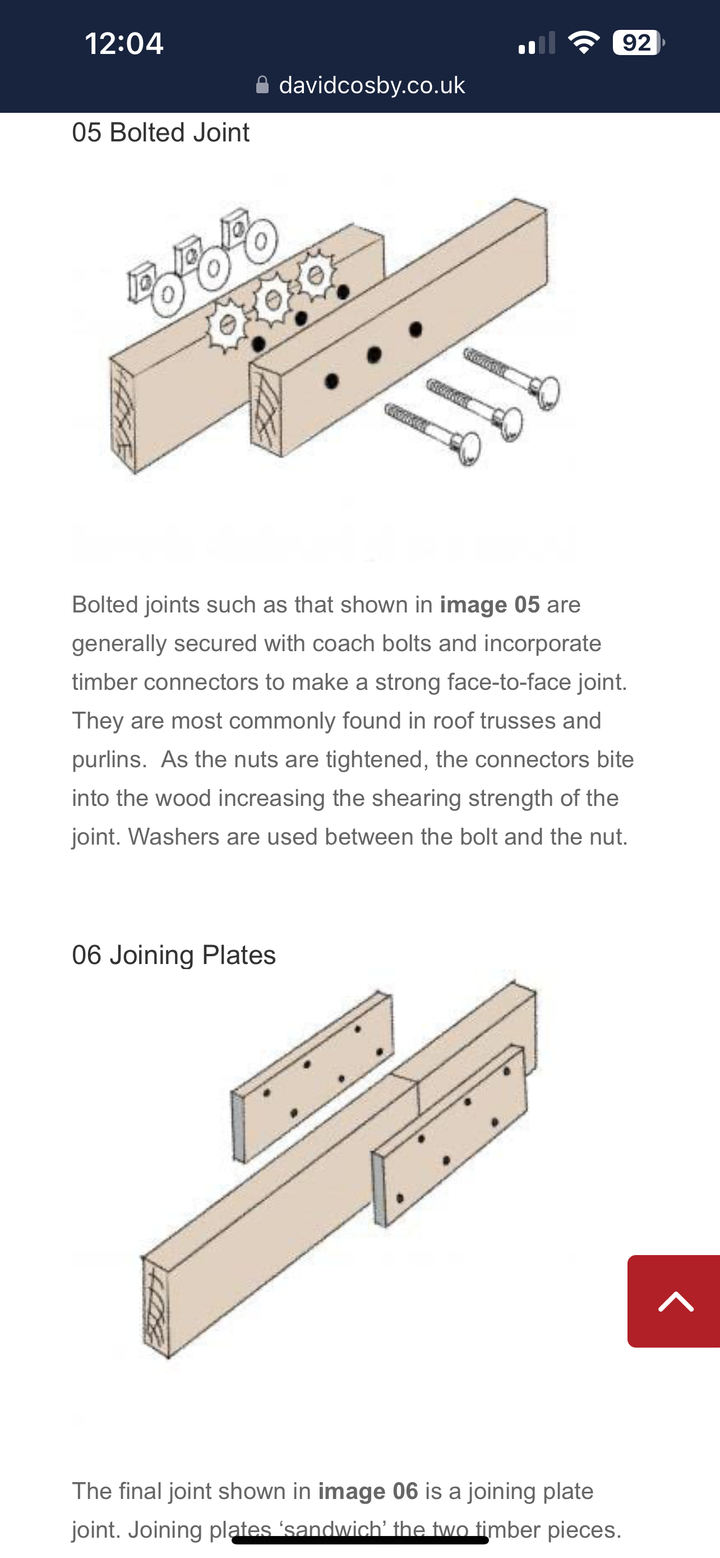

Was thinking overlap although most examples I’ve found people seem to be using plates either side made of the same size timber as the joists. One large overlap of the same size joist using coach bolts and the spiked inner washers seem the most sensible. I purchased 3m joists just incase so I’ll overlap as much as I can get in. Thanks all.

LooneyTunes said:

You’re looking at more than doubling the clear span without increasing the dimensions of the joist or adding any additional support?

You’d have to be quite lucky for that to work, irrespective of how you join them.

Have you looked at any span tables to see what size you should be using and how it compares to what is already there?

This would be a big worry normally but 8 x 2 is a big joist for this job; I wonder what it's supporting.You’d have to be quite lucky for that to work, irrespective of how you join them.

Have you looked at any span tables to see what size you should be using and how it compares to what is already there?

Mad Maximus said:

Was thinking overlap although most examples I’ve found people seem to be using plates either side made of the same size timber as the joists. One large overlap of the same size joist using coach bolts and the spiked inner washers seem the most sensible. I purchased 3m joists just incase so I’ll overlap as much as I can get in. Thanks all.

So effectively you'll be extending a 3m joist by 300mm. Unless there's an unusual load (like a masonry wall) it seems ok. Fit plenty of noggins and bolts; stagger the bolts half of them 1/3 down from the top and half 1/3 up from the bottom. A lot of small dia bolts is better than a few large dia bolts.TA14 said:

Mad Maximus said:

Was thinking overlap although most examples I’ve found people seem to be using plates either side made of the same size timber as the joists. One large overlap of the same size joist using coach bolts and the spiked inner washers seem the most sensible. I purchased 3m joists just incase so I’ll overlap as much as I can get in. Thanks all.

So effectively you'll be extending a 3m joist by 300mm. Unless there's an unusual load (like a masonry wall) it seems ok. Fit plenty of noggins and bolts; stagger the bolts half of them 1/3 down from the top and half 1/3 up from the bottom. A lot of small dia bolts is better than a few large dia bolts.Grumbly said:

TA14 said:

Mad Maximus said:

Was thinking overlap although most examples I’ve found people seem to be using plates either side made of the same size timber as the joists. One large overlap of the same size joist using coach bolts and the spiked inner washers seem the most sensible. I purchased 3m joists just incase so I’ll overlap as much as I can get in. Thanks all.

So effectively you'll be extending a 3m joist by 300mm. Unless there's an unusual load (like a masonry wall) it seems ok. Fit plenty of noggins and bolts; stagger the bolts half of them 1/3 down from the top and half 1/3 up from the bottom. A lot of small dia bolts is better than a few large dia bolts.I'm not sure I like the plated design but is moot given this hasn't been chosen.

I'm not sure what you gain by staggering bolts though. What's the rationale for this when the primary loading results in beam bending? Genuine question as placing bolts along the neutral axis seems logical.

I can well imagine bearing failure to be critical. Once you have the bolts sized just make sure the shank is a snug fit with the hole. Any clearance is not good in this respect.

TA14 said:

LooneyTunes said:

You’re looking at more than doubling the clear span without increasing the dimensions of the joist or adding any additional support?

You’d have to be quite lucky for that to work, irrespective of how you join them.

Have you looked at any span tables to see what size you should be using and how it compares to what is already there?

This would be a big worry normally but 8 x 2 is a big joist for this job; I wonder what it's supporting.You’d have to be quite lucky for that to work, irrespective of how you join them.

Have you looked at any span tables to see what size you should be using and how it compares to what is already there?

8x2 also obviously has different span capabilities depending on its rating.

Zero Fuchs said:

Grumbly said:

TA14 said:

Mad Maximus said:

Was thinking overlap although most examples I’ve found people seem to be using plates either side made of the same size timber as the joists. One large overlap of the same size joist using coach bolts and the spiked inner washers seem the most sensible. I purchased 3m joists just incase so I’ll overlap as much as I can get in. Thanks all.

So effectively you'll be extending a 3m joist by 300mm. Unless there's an unusual load (like a masonry wall) it seems ok. Fit plenty of noggins and bolts; stagger the bolts half of them 1/3 down from the top and half 1/3 up from the bottom. A lot of small dia bolts is better than a few large dia bolts.I'm not sure I like the plated design but is moot given this hasn't been chosen.

I'm not sure what you gain by staggering bolts though. What's the rationale for this when the primary loading results in beam bending? Genuine question as placing bolts along the neutral axis seems logical.

I can well imagine bearing failure to be critical. Once you have the bolts sized just make sure the shank is a snug fit with the hole. Any clearance is not good in this respect.

Grumbly said:

Yes bolts on the neutral axis, hole clearance just increases deflection.

I don't work with timber structures, mainly metallic, but we apply knock down factors for holes that don't match the shank of the fastener. Bearing allowances fall off a cliff as the hole/shank ratio increases.Appreciate all the input.

It took me a while to work out I am effectively extending a 3m joist by 300mm. Hahaha.

I’ll be using 12mm coach bolts with square washers with dog tooth in the centre.

8 x2 does seem large for the span and indeed it is on the tables but that’s what was put in.

The room is 5m+ x 3.3 ish meters in an extension bedroom . For some reason they put an extra staircase in the centre of the room and I am removing it.

It took me a while to work out I am effectively extending a 3m joist by 300mm. Hahaha.

I’ll be using 12mm coach bolts with square washers with dog tooth in the centre.

8 x2 does seem large for the span and indeed it is on the tables but that’s what was put in.

The room is 5m+ x 3.3 ish meters in an extension bedroom . For some reason they put an extra staircase in the centre of the room and I am removing it.

bobtail4x4 said:

was the stair needed as an additional fire excape?

100% no. It was required as the previous owner was eccentric. The stairs were not given permission. They weren’t supposed to be there. The builder went so far as to even chop out the supports in the brick for the joists that ill be putting in. For whatever reason in went an extra set of stairs.

Edited by Mad Maximus on Saturday 30th November 21:02

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff