S1 Replacement Hood

Discussion

I've purchased a new Cabrio replacement hood for my TVR S1 (1988). I also had the top bar reupholstered because it was cut up in multiple places near the hinge bolts. Unfortunately they covered over the bolt holes in the bar for the collapsible roof stays that hold it in place and I can't find them. I thought this would be easy but everything seems solid underneath ???? I really don't want to screw up an expensive upholstering job by cutting holes in the wrong place.Can anyone provide distance from the center of the bar along with distance from the front or rear for your roof stay attachment points?

My hood stays go onto two studs set into the fibreglass of the targa hoop, they are 805mm between centres. If the trimmer has put a thin layer of sponge under the leathercloth they will be difficult to feel the holes for your bolts. Once you think you're close, poking with a fine needle might find them?

But, of course, as the old saying goes "no two are the same", don't think the budget ran to a tape measure at TVR !!!

Edited by phillpot on Sunday 25th August 21:22

I assume you saw the bits before it was sent away. Does it definitely have a female thread there and not studs?

If they're steel, you should be able to get a reasonably accurate location with a metal detector. I've never cut up a hoop but I assume there's no other metal in there apart from the fixings. The fore and aft position will be fixed by the position of the hoop and the length of the struts, so you should be able to judge that reasonably accurately.

If they're steel, you should be able to get a reasonably accurate location with a metal detector. I've never cut up a hoop but I assume there's no other metal in there apart from the fixings. The fore and aft position will be fixed by the position of the hoop and the length of the struts, so you should be able to judge that reasonably accurately.

Great replies. Thanks. I definitely have female threads in the hoop. I'll do some measurements and mark the spots. Somewhere I have a magnetic stud finder. I'll try that before I do any cutting. You're right, they could have filled the threaded holes with foam. I'll let you know how it comes out.

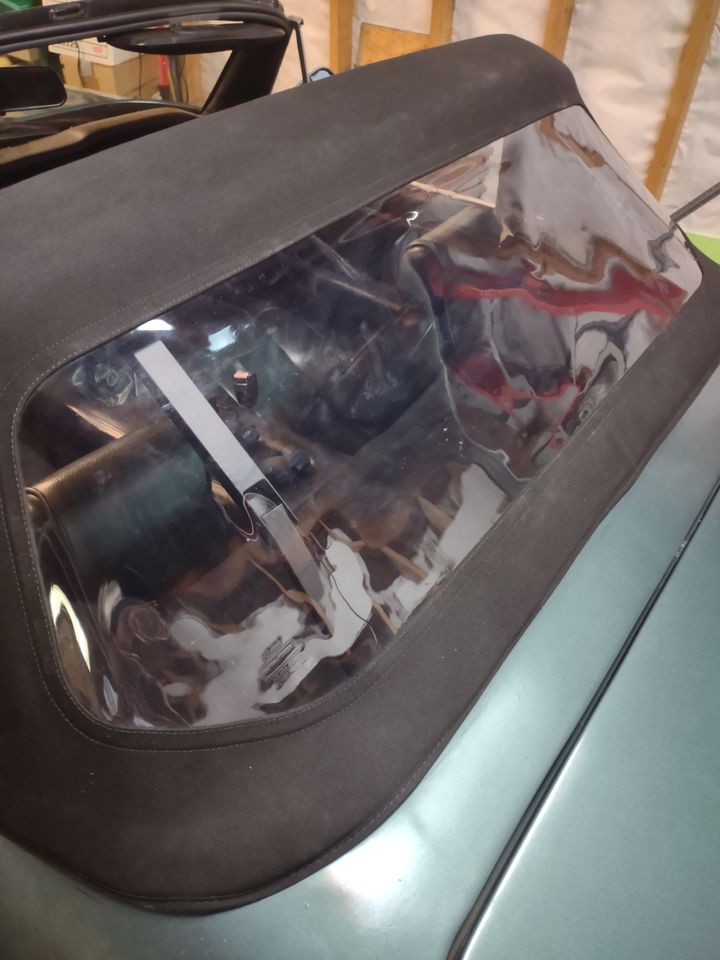

It took awhile, but I found the threaded brass inserts in the targa hoop and installed the roof stays. Thank you for your assistance. Unfortunately I now have another problem. The fabric hood is not taut when the stays are extended. Looks like a long talk with the upholstery guy and some major alterations to the sides.

I called the fitter and explained the situation. We chose a hot day to soften the fabric and vinyl window. I drove the car to the shop. It took three hours and two pairs of very strong hands but the results were very good. And no charge! Now I have to install the weather stripping. Thanks for all the assistance.

It required tightening in multiple directions. To find out what I was dealing with I had to carefully remove the fabric from the targa hoop using a heat gun and occasionally a putty knife. The adhesive used is the same contact cement used to glue Formica laminate to counter tops. Once removed I temporarily locked the targa bar in place with pieces of pipe insulation and tape. Then I started pulling the fabric forward and to the sides (both directions) until I figured out what had to be done to get the wrinkles and waves out. In my case the fabric had to be pulled forward about an inch and then to the sides, one more than the other. It was at this point I decided it was a job for a professional. When I took it to the shop they did same experimental tugging and stretching, then shot the adhesive on the bar and the underside of the cloth. I held the bar locked in place while two of them started pulling the fabric until the vinyl window was as tight as they could get it, then pressed the adhesive prepared edges in place on the bar. Once in place they trimmed off the excess fabric, opened the targa panel slots and worked their way down the sides finally doing a nice tuck and fold at the bottom of the bar. Some advice: plan to do the job with the fabric and vinyl warm to allow them to stretch. A hot day is a good idea. Make sure the Velcro strips on the sides can still be engaged with those on the body. If doing it yourself, memorize the tuck and fold used to finish the bottoms of the targa hoop. You'll likely have extra fabric there.

Best of luck.

Best of luck.

Gassing Station | S Series | Top of Page | What's New | My Stuff