Chimaera rough idle confusion

Discussion

Hi all

I'm hoping someone will kindly share their wisdom because I've run out of ideas/knowledge on this one!

Long story short(ish)...

I have a 1997 Chimaera 500 that would not start due to a lack of spark on the king lead. Tried new coils/amps and swapped leads, no joy, even bought a new hall sensor for the dizzy, but still nothing. I did manage to create a spark manually by rolling a screwdriver over the hall sensor so I figured there was a problem somewhere in the dizzy preventing the spark triggering. I broke a plastic part in the dizzy trying to investigate further (doh!), so bit the bullet and splashed out on a 123 Ignition, hoping never to have similar issues again. After fitting the 123 dizzy the car started fine and I was hoping to get it on the rollers to set it up properly, but unfortunately it still wasn't/isn't running right...

I bought 4 x sparkrite plug testers and checked the sparks on each bank. This showed that plug #6 occasionally had a weak to no spark when the rough running occurred - there would be a drop in rpm and the motor would struggle to keep running until a few seconds later when something corrected itself and the rpm jumped up. I thought 'ah ha' and changed #6 HT lead (and plug) with the neighbouring one that was running fine. It made no difference. #6 still bad. My confusion really set in when I disconnected #6 HT lead and held it to the engine block to see the spark and I saw the same behaviour i.e. rough running when the spark quality dropped or disappeared - even though it wasn't connected to the plug! I thought it was the mis-fire causing the rough running, but it's almost like something else is causing the rpms to drop at the same time as affecting the spark to #6.

Things I tried along the way:

New AFM

New Flame-Thrower coil (recommended for the 123 ignition)

Cleaning the stepper motor (proved working using RoverGauge)

Cleaning around the butterfly air inlet flap (not sure of its proper name)

Checked the ECU for connections/dampness

Checked the ignition (and fuel) relay

The timing is set to roughly 8 degrees BTDC.

RoverGauge shows everything as normal (AFAIK) with no fault codes - apart from 100% long term trim on both lambdas, but I'm thinking that's down to the mis-fire(?)

Would anyone be able to help me with next steps or let me know anything I've missed please?

Maybe take it somewhere for a vacuum leak check??

Many thanks in advance.

Tim

I'm hoping someone will kindly share their wisdom because I've run out of ideas/knowledge on this one!

Long story short(ish)...

I have a 1997 Chimaera 500 that would not start due to a lack of spark on the king lead. Tried new coils/amps and swapped leads, no joy, even bought a new hall sensor for the dizzy, but still nothing. I did manage to create a spark manually by rolling a screwdriver over the hall sensor so I figured there was a problem somewhere in the dizzy preventing the spark triggering. I broke a plastic part in the dizzy trying to investigate further (doh!), so bit the bullet and splashed out on a 123 Ignition, hoping never to have similar issues again. After fitting the 123 dizzy the car started fine and I was hoping to get it on the rollers to set it up properly, but unfortunately it still wasn't/isn't running right...

I bought 4 x sparkrite plug testers and checked the sparks on each bank. This showed that plug #6 occasionally had a weak to no spark when the rough running occurred - there would be a drop in rpm and the motor would struggle to keep running until a few seconds later when something corrected itself and the rpm jumped up. I thought 'ah ha' and changed #6 HT lead (and plug) with the neighbouring one that was running fine. It made no difference. #6 still bad. My confusion really set in when I disconnected #6 HT lead and held it to the engine block to see the spark and I saw the same behaviour i.e. rough running when the spark quality dropped or disappeared - even though it wasn't connected to the plug! I thought it was the mis-fire causing the rough running, but it's almost like something else is causing the rpms to drop at the same time as affecting the spark to #6.

Things I tried along the way:

New AFM

New Flame-Thrower coil (recommended for the 123 ignition)

Cleaning the stepper motor (proved working using RoverGauge)

Cleaning around the butterfly air inlet flap (not sure of its proper name)

Checked the ECU for connections/dampness

Checked the ignition (and fuel) relay

The timing is set to roughly 8 degrees BTDC.

RoverGauge shows everything as normal (AFAIK) with no fault codes - apart from 100% long term trim on both lambdas, but I'm thinking that's down to the mis-fire(?)

Would anyone be able to help me with next steps or let me know anything I've missed please?

Maybe take it somewhere for a vacuum leak check??

Many thanks in advance.

Tim

Yep, I have the leads with the ceramic extenders which have always been great. I have just bought a new (cheaper) set as the next thing to try actually, so I'll give it a go, thanks.

When I tested the spark against the block I had no extender on though, so I'm not expecting that to be the problem.

When I tested the spark against the block I had no extender on though, so I'm not expecting that to be the problem.

> You happy it's wired right ?

I believe so. It's pretty simple. Just 2 wires + an earth (optional).

> Does the dizzy spin ok when cranking?

The rotor arm? I haven't cranked it with the cap off to watch, but I presume so as the engine starts no problem and the other 7 cylinders seem fine.

I believe so. It's pretty simple. Just 2 wires + an earth (optional).

> Does the dizzy spin ok when cranking?

The rotor arm? I haven't cranked it with the cap off to watch, but I presume so as the engine starts no problem and the other 7 cylinders seem fine.

Since the 123 is electronic, and you've been swapping HT leads, is it possible the fault lies with the 123 unit?

Especially since you swapped the HT lead around but the problem stayed on the same cylinder.

I wondered whether the spark plug thread in the block is gummed up and preventing the spark plug from earthing, but your testing may have debunked that thought.

Your notes didn't say whether you replaced the spark plugs, but then your swapping suggests they're working.

I've got a spare old Lucas amp and old Bosch coil that both work, so if you're anywhere near me in Amersham you'd be welcome to try them.

Not sure that's your issue though.

The other thing is Steve_D's wiring diagrams that might help you trace possibilities - I can email them to you if you PM me your email address.

Might be time to take it in to a mechanic with an auto-electrician

Especially since you swapped the HT lead around but the problem stayed on the same cylinder.

I wondered whether the spark plug thread in the block is gummed up and preventing the spark plug from earthing, but your testing may have debunked that thought.

Your notes didn't say whether you replaced the spark plugs, but then your swapping suggests they're working.

I've got a spare old Lucas amp and old Bosch coil that both work, so if you're anywhere near me in Amersham you'd be welcome to try them.

Not sure that's your issue though.

The other thing is Steve_D's wiring diagrams that might help you trace possibilities - I can email them to you if you PM me your email address.

Might be time to take it in to a mechanic with an auto-electrician

Thanks Pal, have PM'd you.

Yeah, I forgot to mention I have all new plugs too. I've also tried my original lucas coil and two new viper coils along the way! The 123 ignition has an internal amp, so that's out of the equation.

I tried some local old school auto electrician types but they are all waiting on hip ops or have bad knees so 'don't want to be crawling in and out of a TVR' I'm just left with the local bosch garage at £120/hr for diagnostics - It may well come to that!

I also spoke to the 123 supplier who gave me a bunch of tests to try. Can't remember all of them off the top of my head, but only some seemed relevant and others I didn't have the equipment for. I did suspect the 123 unit, but the engine dipping without #6 lead connected makes me think it's something else.

Yeah, I forgot to mention I have all new plugs too. I've also tried my original lucas coil and two new viper coils along the way! The 123 ignition has an internal amp, so that's out of the equation.

I tried some local old school auto electrician types but they are all waiting on hip ops or have bad knees so 'don't want to be crawling in and out of a TVR' I'm just left with the local bosch garage at £120/hr for diagnostics - It may well come to that!

I also spoke to the 123 supplier who gave me a bunch of tests to try. Can't remember all of them off the top of my head, but only some seemed relevant and others I didn't have the equipment for. I did suspect the 123 unit, but the engine dipping without #6 lead connected makes me think it's something else.

So if you have replaced all the HT components and still have a problem, have you routed the HT leads correctly? It has a very specific routing path because if you cross or mis route HT leads you can induce cross firing between the leads leading to erratic sparks occurring. Also check the HT leads in the dark and look for any slight blue glows that would indicate leakage. In terms of the 123 / coil and trigger, its all exactly the same system for all 8 cylinders, it only becomes specific between the rotor arm and HT lead number 6 so you can discount anything "upstream" of that point. The tip of the rotor arm is a very specific design in so much it has to arc across the whole spectrum of the ignition advance so thats why its a wide blade to cope with the timing shift. It also means the leading edge of the rotor arm has to be just aligning with the pick up point at maximum advance and the trailing edge leaving at minimum advance. In theory at least you should not be able to mis align things so this cant happen, but given a bit of cam mistiming or like it may be possible to cause the rotor to be too far away from its corresponding plug lead take off to maintain a decent spark under all conditions, it might even jump to another cylinder if its a long way off. Unfortunately the only way to be sure this is not an issue is to cut a hole in an old distributor cap and look at the rotor position at about 8' and 28' BTDC crank position and make sure the rotor is perfectly aligned with the copper post between these figures.

In terms of old school diagnostics the old Crypton or Sun ignition scopes could display HT waveforms. They are very specific as you should see the HT build to the point of ignition, then drop sharply as the plug arcs for the burn period. If you can find someone who can look at several cylinder traces at the same time you should at least see if its lack of peak HT or low burn period causing the misfire.

Another thing to bear in mind is the spark arc voltage depends on the combustion chamber condition. Plain air has quite a low resistance to an arc, but if you add petrol and then increase the compression the resistance to the arc goes up, so it takes a higher voltage to start the spark. If you had say oil getting into the combustion chamber it might be enough to stop the arc occurring, and this would stop you seeing the flash on a test plug cap as the arc never occurs, so its not a voltage fault but a combustion chamber condition fault. Likewise a sooty plug leaks all the HT away as it builds so you never see the flash. Pull plug number 6 out and have a good look at its electrode compared to the working cylinders.

In terms of your long term trim, is it adding or removing fuel? Short term will also spike at 100% adding fuel during a misfire. If its is adding, it could be the mis fire, but its showing on both banks yet you say its only plug 6?

More generally have you put a test meter on the coils 12v ignition supply to make sure its not dropping ? Definitely got + and -ve the correct way around on the coil? The coils HT circuit does not ground through the case but the -ve 12v terminal so its polarity is critical.

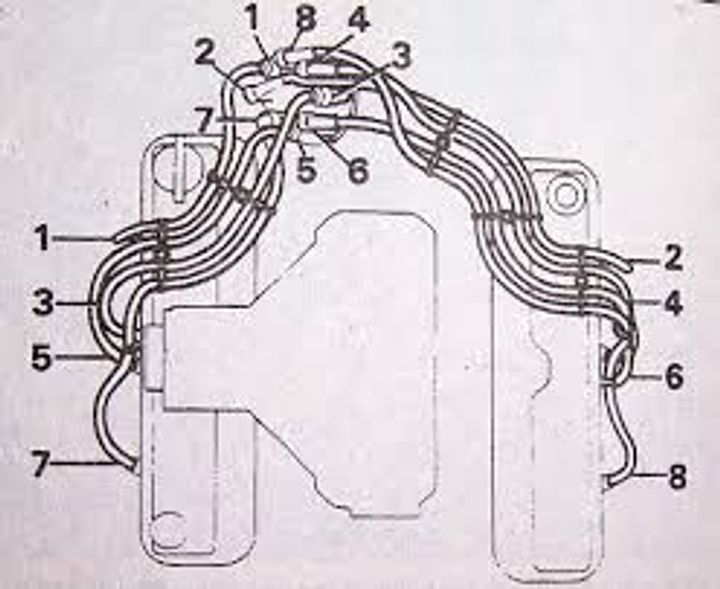

Here is your HT routing:

In terms of old school diagnostics the old Crypton or Sun ignition scopes could display HT waveforms. They are very specific as you should see the HT build to the point of ignition, then drop sharply as the plug arcs for the burn period. If you can find someone who can look at several cylinder traces at the same time you should at least see if its lack of peak HT or low burn period causing the misfire.

Another thing to bear in mind is the spark arc voltage depends on the combustion chamber condition. Plain air has quite a low resistance to an arc, but if you add petrol and then increase the compression the resistance to the arc goes up, so it takes a higher voltage to start the spark. If you had say oil getting into the combustion chamber it might be enough to stop the arc occurring, and this would stop you seeing the flash on a test plug cap as the arc never occurs, so its not a voltage fault but a combustion chamber condition fault. Likewise a sooty plug leaks all the HT away as it builds so you never see the flash. Pull plug number 6 out and have a good look at its electrode compared to the working cylinders.

In terms of your long term trim, is it adding or removing fuel? Short term will also spike at 100% adding fuel during a misfire. If its is adding, it could be the mis fire, but its showing on both banks yet you say its only plug 6?

More generally have you put a test meter on the coils 12v ignition supply to make sure its not dropping ? Definitely got + and -ve the correct way around on the coil? The coils HT circuit does not ground through the case but the -ve 12v terminal so its polarity is critical.

Here is your HT routing:

Edited by blitzracing on Monday 10th June 21:37

Thanks all for your replies.

Andy:

> Do a vacuum or smoke test before doing anything else

Yep, I think definitely worth doing once I've ruled out the further checks I can do myself, thanks.

Andrew:

> king lead from coil direct to a plug which is resting on the block

I did this but without the plug. I can try with a plug to see if it makes a difference.

Mark, many thanks for your detailed and well thought out response. Please see my replies to your questions below...

> have you routed the HT leads correctly?

Not looking at the diagram, no. Mine do cross over in several places. I'll sort that out as the next step. That said, I have closely monitored for sparks in the dark several times and haven't noticed any sparks or blue glows, but will check again.

> it only becomes specific between the rotor arm and HT lead number 6 so you can discount anything "upstream"

This is why I was really confused when I saw the same problems occurring even without #6 lead connected to the plug - in that situation there is nothing else "downstream"

> cut a hole in an old distributor cap

I could maybe try and mark the exact position of the copper post on the dizzy body and hand-crank to see if the rotor range is aligned. (BTW, I didn't mention, but I also tried a Distributor Doctor rotor and cap)

> find someone who can look at several cylinder traces at the same time

Yeah, this is where I was heading with the "local old school auto electrician types" because one of them advised me to hook it up to an oscilloscope, but I haven't found anyone yet.

> spark arc voltage depends on the combustion chamber condition

Great suggestion, but I believe this was ruled out by observing the spark when not connected to the plug. I will definitely pull plug 6 out and take a look at the condition though.

> long term trim, is it adding or removing fuel

100% adding on both

> Short term will also spike at 100% adding fuel during a misfire

Makes sense, but didn't observe that

> showing on both banks yet you say its only plug 6

Very good point. I hadn't thought of that. Not sure where that leave me though. Presumably I have a fueling/lambda issue too then??

> have you put a test meter on the coils 12v ignition supply to make sure its not dropping

Not while running, no. I'll give that a try too, thanks!

> Definitely got + and -ve the correct way around on the coil

Pretty sure, yes.

Andy:

> Do a vacuum or smoke test before doing anything else

Yep, I think definitely worth doing once I've ruled out the further checks I can do myself, thanks.

Andrew:

> king lead from coil direct to a plug which is resting on the block

I did this but without the plug. I can try with a plug to see if it makes a difference.

Mark, many thanks for your detailed and well thought out response. Please see my replies to your questions below...

> have you routed the HT leads correctly?

Not looking at the diagram, no. Mine do cross over in several places. I'll sort that out as the next step. That said, I have closely monitored for sparks in the dark several times and haven't noticed any sparks or blue glows, but will check again.

> it only becomes specific between the rotor arm and HT lead number 6 so you can discount anything "upstream"

This is why I was really confused when I saw the same problems occurring even without #6 lead connected to the plug - in that situation there is nothing else "downstream"

> cut a hole in an old distributor cap

I could maybe try and mark the exact position of the copper post on the dizzy body and hand-crank to see if the rotor range is aligned. (BTW, I didn't mention, but I also tried a Distributor Doctor rotor and cap)

> find someone who can look at several cylinder traces at the same time

Yeah, this is where I was heading with the "local old school auto electrician types" because one of them advised me to hook it up to an oscilloscope, but I haven't found anyone yet.

> spark arc voltage depends on the combustion chamber condition

Great suggestion, but I believe this was ruled out by observing the spark when not connected to the plug. I will definitely pull plug 6 out and take a look at the condition though.

> long term trim, is it adding or removing fuel

100% adding on both

> Short term will also spike at 100% adding fuel during a misfire

Makes sense, but didn't observe that

> showing on both banks yet you say its only plug 6

Very good point. I hadn't thought of that. Not sure where that leave me though. Presumably I have a fueling/lambda issue too then??

> have you put a test meter on the coils 12v ignition supply to make sure its not dropping

Not while running, no. I'll give that a try too, thanks!

> Definitely got + and -ve the correct way around on the coil

Pretty sure, yes.

I will reiterate that I'm no expert, but 100% adding on both trims sounds like the lambda sensors are worth a look.

If they're both giving the same input to the ECU, there might be something there.

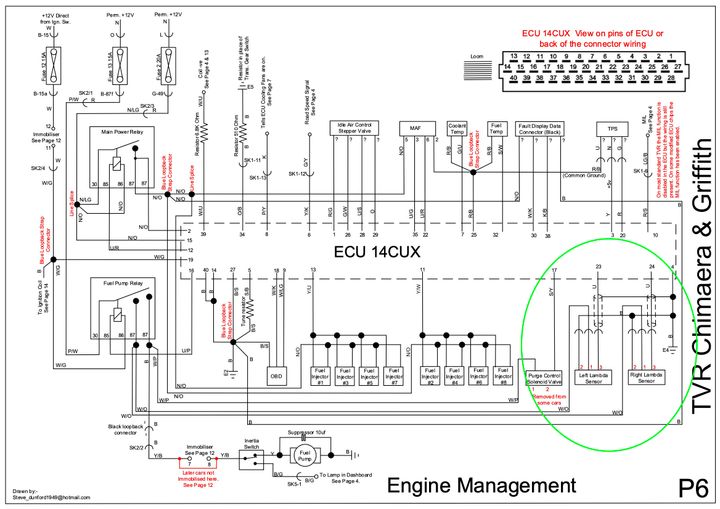

On this diagram it shows that the lambdas are relatively isolated, and have two common earth links (or at least have two earths), as well as the W/O wires going to a common point on the fuel pump relay, so those wires could be worth testing.

In my wildest imagination there's a nice and simple connection issue on the socket of your fuel pump relay, your ECU is trying to correct wildly and no.6 is bearing the brunt (not sure how that might work), and once fixed your world will right itself...

I'm not intending to send you down a rabbit hole, just trying to think around what you're describing.

If they're both giving the same input to the ECU, there might be something there.

On this diagram it shows that the lambdas are relatively isolated, and have two common earth links (or at least have two earths), as well as the W/O wires going to a common point on the fuel pump relay, so those wires could be worth testing.

In my wildest imagination there's a nice and simple connection issue on the socket of your fuel pump relay, your ECU is trying to correct wildly and no.6 is bearing the brunt (not sure how that might work), and once fixed your world will right itself...

I'm not intending to send you down a rabbit hole, just trying to think around what you're describing.

Can I suggest going right back to basics here.

When you say car is running rough what do you mean? Is it misfiring?? Is it running on 7 cylinders.

If running on 7 cyls do you know which one? Easy way to tell is temperature of each exhaust manifold (try holding a cable tie end on each branch - if you have a cylinder not running it will not melt the cable tie.

Roverguage should show a fault if you have a missing cylinder. Forget the lambda at the moment.

If you identify a missing cylinder remove spark plug and short it to engine block to check you have a good spark - if you dont it is the ht lead or distributor

Don't do anything else until you have established the above.

If you can get to Hastings I'm happy to have a look. (I fixed a very similar issue with mine but you have to change one thing at a time!!)

When you say car is running rough what do you mean? Is it misfiring?? Is it running on 7 cylinders.

If running on 7 cyls do you know which one? Easy way to tell is temperature of each exhaust manifold (try holding a cable tie end on each branch - if you have a cylinder not running it will not melt the cable tie.

Roverguage should show a fault if you have a missing cylinder. Forget the lambda at the moment.

If you identify a missing cylinder remove spark plug and short it to engine block to check you have a good spark - if you dont it is the ht lead or distributor

Don't do anything else until you have established the above.

If you can get to Hastings I'm happy to have a look. (I fixed a very similar issue with mine but you have to change one thing at a time!!)

If you can run Rover Gauge then you could create a log file for me and I will analyse it for you, as I've done for many on here and facebook forums.

I can tell you if all the inputs and outputs are working within normal boundaries, especially the MAF sensor which is critical and often the cause of fueling issues.

LOGGING PROCEDURE

1. Plug the 14CUX cable into the loom connector on the car

2. Start RoverGauge software

3. Setup RG opTions settings as follows

a. COM - COMx (use whatever COM port works for you)

b . Speed - mph

c. Temperature – Celsius

d. Parameters to log – all but not road speed or gear selection

4. Set RoverGauge main screen as follows:

a. MAF – Direct

b. Throttle – Absolute

c. Trim – Short Term

5. Turn on the ignition switch and press ‘connect’ to link 14CUX with your laptop.

6. Preferably start the car from cold.

7. Start logging the data (Start Log F5) and drive the car for 15 minutes on a local roads (eg A or B class to get varying running conditions) then stop the car and allow the engine to idle for a further 5 to 10 minutes. (DO NOT TOUCH ANY OF THE CONTROLSAT THIS STAGE)

8. You can now stop logging data by pressing “Stop Log F7”

9. Send the logfiles (held in a sub folder where RoverGauge is) to me (I will msg you my email address)

I can tell you if all the inputs and outputs are working within normal boundaries, especially the MAF sensor which is critical and often the cause of fueling issues.

LOGGING PROCEDURE

1. Plug the 14CUX cable into the loom connector on the car

2. Start RoverGauge software

3. Setup RG opTions settings as follows

a. COM - COMx (use whatever COM port works for you)

b . Speed - mph

c. Temperature – Celsius

d. Parameters to log – all but not road speed or gear selection

4. Set RoverGauge main screen as follows:

a. MAF – Direct

b. Throttle – Absolute

c. Trim – Short Term

5. Turn on the ignition switch and press ‘connect’ to link 14CUX with your laptop.

6. Preferably start the car from cold.

7. Start logging the data (Start Log F5) and drive the car for 15 minutes on a local roads (eg A or B class to get varying running conditions) then stop the car and allow the engine to idle for a further 5 to 10 minutes. (DO NOT TOUCH ANY OF THE CONTROLSAT THIS STAGE)

8. You can now stop logging data by pressing “Stop Log F7”

9. Send the logfiles (held in a sub folder where RoverGauge is) to me (I will msg you my email address)

Gassing Station | Chimaera | Top of Page | What's New | My Stuff