Tightening up a 300Nm Crankshaft bolt. Suggestions?

Discussion

This is going to seem like a silly question but I figured I best ask!

As some of you know I have changed the crankshaft seal on my W124 250D Manual; fitted with the OM602 engine. When I undid the bolt I used the starter motor trick to undo it, as holding the car in gear with the handbrake on wasn't enough to stop the engine turning over.

I've refitted it but again I was unable to use my breaker bar for the aforementioned reasons. Thus I used my Kielder rattle gun. Going by the car wheel nuts it can tighten to around 100-120Nm on a 17mm bolt if it's rattling for long enough. I am aware that the torque does up up for socket sizes and being 27mm I'm hoping it went up quite a bit. Using my torque wrench I know the bolt is done up to at least 150Nm, but again the engine/car turns after that despite having it in gear with the handbrake on.

I'm also worried about having 300NM of force going through the clutch and drivetrain damaging things ; I've heard about this before with tightening things, but is it valid?

One way around it is to get a flywheel lock. But they are hard to come by and tend to be £50-60. These use two bolts from the sump and slot into the flywheel via a small aperture in the bottom of the sump.

I've debated a screwdriver being used but I'm worried with that amount of torque it will snap, leaving me with a bigger problem (swarf in the bellhousing). I've never heard of a crank bolt being that tight previously; normally figures of 90-100Nm seem more normal.

My question to you is bar buying the tool what else do you suggest? Am I right to be worried about damage to the drivetrain if I get a friend to stamp on the brake pedal as I tighten the crank bolt? I've previously used a screwdriver but never for things this tight. Part of me wants to think it is fine now (it's been fine in the workshop) but taking it to France has me wanting to eliminate potential issues for the trip. That and the oil pump is driven off the crank.

As some of you know I have changed the crankshaft seal on my W124 250D Manual; fitted with the OM602 engine. When I undid the bolt I used the starter motor trick to undo it, as holding the car in gear with the handbrake on wasn't enough to stop the engine turning over.

I've refitted it but again I was unable to use my breaker bar for the aforementioned reasons. Thus I used my Kielder rattle gun. Going by the car wheel nuts it can tighten to around 100-120Nm on a 17mm bolt if it's rattling for long enough. I am aware that the torque does up up for socket sizes and being 27mm I'm hoping it went up quite a bit. Using my torque wrench I know the bolt is done up to at least 150Nm, but again the engine/car turns after that despite having it in gear with the handbrake on.

I'm also worried about having 300NM of force going through the clutch and drivetrain damaging things ; I've heard about this before with tightening things, but is it valid?

One way around it is to get a flywheel lock. But they are hard to come by and tend to be £50-60. These use two bolts from the sump and slot into the flywheel via a small aperture in the bottom of the sump.

I've debated a screwdriver being used but I'm worried with that amount of torque it will snap, leaving me with a bigger problem (swarf in the bellhousing). I've never heard of a crank bolt being that tight previously; normally figures of 90-100Nm seem more normal.

My question to you is bar buying the tool what else do you suggest? Am I right to be worried about damage to the drivetrain if I get a friend to stamp on the brake pedal as I tighten the crank bolt? I've previously used a screwdriver but never for things this tight. Part of me wants to think it is fine now (it's been fine in the workshop) but taking it to France has me wanting to eliminate potential issues for the trip. That and the oil pump is driven off the crank.

Edited by SebringMan on Tuesday 8th May 10:56

xjay1337 said:

Why worried about 300nm going through the gearbox etc when the engine produces more that that... get someone to sit in the car on the brakes. Easy.

Except mine doesn't. It's a 2.5 non-turbo diesel making 94BHP and IIRC 140Nm of torque. I think the most powerful diesel W124 made 131BHP; the 300D with the OM603 as well as the non-turbo OM606; Whether either came with a manual 'box I don't know.Jakg said:

ou've lost me there?

From a few user manuals I had read (and thinking about it also (Force x Distance=Work) both Makita and Kielder say that their rattle guns go up to 1000Nm and 450Nm respectively. They say up to and then plot a graph in the manuals showing what torque to expect on your bolts, with the relationship being the size of the bolt and the torque being proportional between the two.I only put that there to give an idea/guestimate of how tight the bolt may be.

http://icmsmakita.eu/cms/custom/uk/user_manual/DTW...

Page 6 of that manual will make it clearer as to what I am talking about

.

.Well, I've admitted defeat.

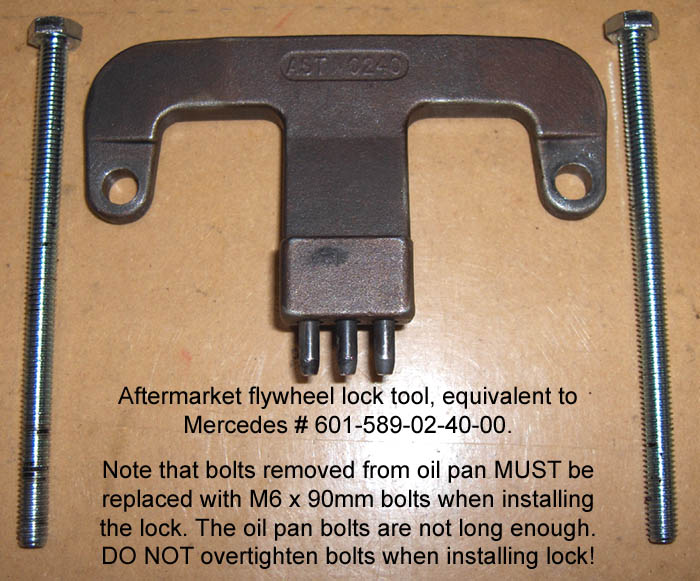

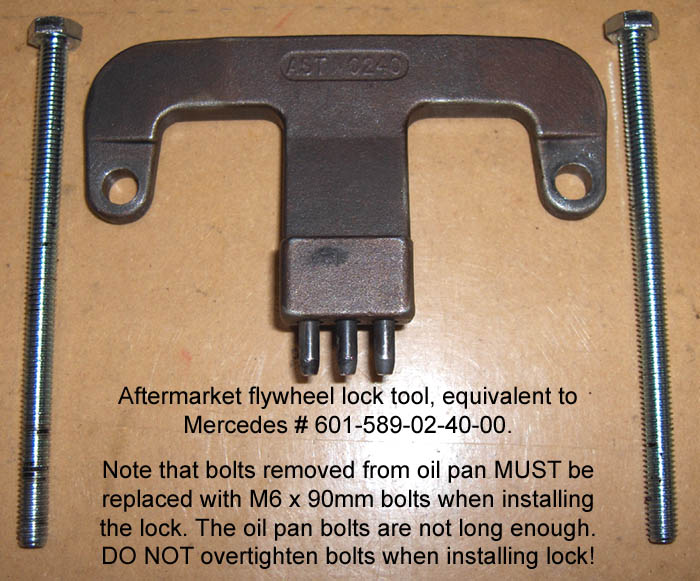

I've decided to go with this:

That is a replica of the factory tool. You remove two sump bolts, put that into the factory aperture and then tighten/loosen the crank bolt as per the factory manual. I sort of don't trust the two bolts but a few people have used these with success it seems after some forum searching.

For those wondering this the link I have got it from:

https://www.ebay.co.uk/itm/Steuerkette-wechseln-We...

I've decided to go with this:

That is a replica of the factory tool. You remove two sump bolts, put that into the factory aperture and then tighten/loosen the crank bolt as per the factory manual. I sort of don't trust the two bolts but a few people have used these with success it seems after some forum searching.

For those wondering this the link I have got it from:

https://www.ebay.co.uk/itm/Steuerkette-wechseln-We...

SebringMan said:

xjay1337 said:

Why worried about 300nm going through the gearbox etc when the engine produces more that that... get someone to sit in the car on the brakes. Easy.

Except mine doesn't. It's a 2.5 non-turbo diesel making 94BHP and IIRC 140Nm of torque. I think the most powerful diesel W124 made 131BHP; the 300D with the OM603 as well as the non-turbo OM606; Whether either came with a manual 'box I don't know.

Gassing Station | Mercedes | Top of Page | What's New | My Stuff