do i want/need a 3d printer?

Discussion

so after watching a video about 3d printing your own cable management bits by handsonkatie i thought do i want/need a 3d printer

had a look at bambu labs as its what she mentioned but £169 to £1099 is a hell of a difference in price but i have no idea what specs id need as i have no idea what id honestly use it for other than some cable management stuff and then i could just pay someone to print that for me.

but i like toys

so im still looking

any suggestions of what to look at or for?

budget i dont have one as this is totally spur of the moment so really lower the better but as i understand it you tend to be able to upgrade bits to make them better anyway

so where is a good place to start?

had a look at bambu labs as its what she mentioned but £169 to £1099 is a hell of a difference in price but i have no idea what specs id need as i have no idea what id honestly use it for other than some cable management stuff and then i could just pay someone to print that for me.

but i like toys

so im still looking

any suggestions of what to look at or for?

budget i dont have one as this is totally spur of the moment so really lower the better but as i understand it you tend to be able to upgrade bits to make them better anyway

so where is a good place to start?

Do you intened to print alot of stuff?

If you only printing a very few gadgets, probably easier and cheap to get someone to print it

make your own 3D model/CAD?

there are many model free/cost in the internet, but it could be hard to find the pefect fit, Blender and Fusion 360 is free so you might want to consider making your own model

what will you be printing mostly?

I print diorama, and N gague scenary, so a bambu lab mini or standard 220/250 printer work for me, if you like to print helmet for cosplay you might want a bigger printer, on the other hand if you printing figure like warhammer a small but high def printer (e.g. Resin printer) might be work. the bigger print area the more expensive the printer and the more space it take up, and Resin printer could get very messy

do you have the patience to tinker each print file?

leveling the print bed, changing layer height, temperature, infill etc. Even a good printer like bambu lab would require some adjustment. I spend more than 200g of material just to get my printer working.

Sometimes the issue is not your printer but the 3D file or the slicing software.

Do you have the space?

Bed slinger take up some space espeically the larger one, CoreXY arent budget friendly, Resin printer require post curing and washing station. A Print could take more than 24hrs and the printer could get quite noisy and generate a bit of heat. You might also want a environmental chamber to keep the temperature and humidity stable for better quality of print

at the end, once you get the printer setup correctly, you would keep on wanting to print more and more. Welcome to the blackhole

If you only printing a very few gadgets, probably easier and cheap to get someone to print it

make your own 3D model/CAD?

there are many model free/cost in the internet, but it could be hard to find the pefect fit, Blender and Fusion 360 is free so you might want to consider making your own model

what will you be printing mostly?

I print diorama, and N gague scenary, so a bambu lab mini or standard 220/250 printer work for me, if you like to print helmet for cosplay you might want a bigger printer, on the other hand if you printing figure like warhammer a small but high def printer (e.g. Resin printer) might be work. the bigger print area the more expensive the printer and the more space it take up, and Resin printer could get very messy

do you have the patience to tinker each print file?

leveling the print bed, changing layer height, temperature, infill etc. Even a good printer like bambu lab would require some adjustment. I spend more than 200g of material just to get my printer working.

Sometimes the issue is not your printer but the 3D file or the slicing software.

Do you have the space?

Bed slinger take up some space espeically the larger one, CoreXY arent budget friendly, Resin printer require post curing and washing station. A Print could take more than 24hrs and the printer could get quite noisy and generate a bit of heat. You might also want a environmental chamber to keep the temperature and humidity stable for better quality of print

at the end, once you get the printer setup correctly, you would keep on wanting to print more and more. Welcome to the blackhole

I'm currently printing some hinges for a parcel box I'm making.

Recently printed some battery holders for my tools.

The best thing is that there are so many designs online you invariably don't need to 3D model anything, just download an .STL file and off you go.

I calibrated mine ages ago and it now just works.

It's a learning curve, but once you get to the point where everything is working it's all good.

Recently printed some battery holders for my tools.

The best thing is that there are so many designs online you invariably don't need to 3D model anything, just download an .STL file and off you go.

I calibrated mine ages ago and it now just works.

It's a learning curve, but once you get to the point where everything is working it's all good.

Buy an Ender 3 Pro for a couple of hundred quid and see how you get on.

Don't worry about cad and designing your own parts as there are many files ready to print on sites like thingiverse, learing the cad is quite a steep learning curve but not a blocker to having a useful 3d print capability.

Don't worry about cad and designing your own parts as there are many files ready to print on sites like thingiverse, learing the cad is quite a steep learning curve but not a blocker to having a useful 3d print capability.

otolith said:

Does anyone use them to print scarce/expensive/improved automotive components? Is the material strength comparable to commercially produced moulded plastic parts?

Yes people do, but they tend to be using fairly good printers and have done a lot of learning.I know someone has printed a lot of plastic and rubbery bits for some 90s bikes for instance.

It helps if you also have a scanner and the original part to copy.

I built mine in lockdown from a really cheap and nasty kit.

I don't use it all that much but I'm tempted by an upgrade, or to re-build it with a better framework and moving parts.

The CAD is as difficult as you make it.

A lot of what I print is brackets and spacers and fairly simple shapes.

I've tried a few different packages, there's a really basic one called 'selfcad' which can be really quick and easy for beginners, if you want e.g. a rectangular lump with a few holes in it!

I'm a few weeks into ownership of a Bambu Labs P1S and thoroughly enjoying it so far. I saw it as a purchase in the same category as a power washer or a garden shredder, as in something that's not used all the time but really useful to have when you need it.

The only issue I've found is that I'm wondering how I can solve every problem I see around the house by printing something. I've had a bunch of Allen keys lying loose on my desk for months that I didn't really have a place for, so at the weekend I designed and printed a little holder for them. Stuff like that

I do have an advantage in that I've done plenty of 3D modelling so I'm comfortable making my own models to print using Blender. Without that I think I'd be a bit more wary.

And from reading around it feels like they've only recently got to a stage where they are pretty much plug and play. I just wanted to make stuff rather than spend time farting about with the printer itself and so far that's been the case. I've just imported my model, picked the material, pressed go and it's figured it all out itself.

The only issue I've found is that I'm wondering how I can solve every problem I see around the house by printing something. I've had a bunch of Allen keys lying loose on my desk for months that I didn't really have a place for, so at the weekend I designed and printed a little holder for them. Stuff like that

I do have an advantage in that I've done plenty of 3D modelling so I'm comfortable making my own models to print using Blender. Without that I think I'd be a bit more wary.

And from reading around it feels like they've only recently got to a stage where they are pretty much plug and play. I just wanted to make stuff rather than spend time farting about with the printer itself and so far that's been the case. I've just imported my model, picked the material, pressed go and it's figured it all out itself.

durbster said:

I....

The only issue I've found is that I'm wondering how I can solve every problem I see around the house by printing something......

I'm now seeing prjects which might be a lot easier with a CNC router...The only issue I've found is that I'm wondering how I can solve every problem I see around the house by printing something......

There are some interesting CNC router/laser cutter things on ebay.

I haven't used one, but a bambu labs printer would be where my money's at if I had to buy one. Anything lesser is just a waste of time.

I've spent countless hours and a few quid in upgrades trying to get an older Prusa to print correctly. It rarely gets used, it's slow, and it can be a pain in the arse... but it's invaluable when I need it. I mainly use it for car parts, tools and things that require dimensional accuracy.

They are essentially a prototyping tool, and the finished results look and feel like it. They don't have the same finish as an injection moulded part and I think they're wasted on printing little nik naks for the home.

I've spent countless hours and a few quid in upgrades trying to get an older Prusa to print correctly. It rarely gets used, it's slow, and it can be a pain in the arse... but it's invaluable when I need it. I mainly use it for car parts, tools and things that require dimensional accuracy.

They are essentially a prototyping tool, and the finished results look and feel like it. They don't have the same finish as an injection moulded part and I think they're wasted on printing little nik naks for the home.

Edited by fasimew on Monday 15th July 20:50

otolith said:

Does anyone use them to print scarce/expensive/improved automotive components? Is the material strength comparable to commercially produced moulded plastic parts?

I do, the answer regarding strength is yes, no, maybe, sometimes - it depends entirely on what the original part was made off and/or if you are designing specifically for 3D Print. I use a lot of PETG for parts, usually high temp or carbon reinforced (note this is different to the CF powder matt look stuff), ABS and Nylon is also very suitable for automotive parts. PLA and similar very much not.

Few examples,

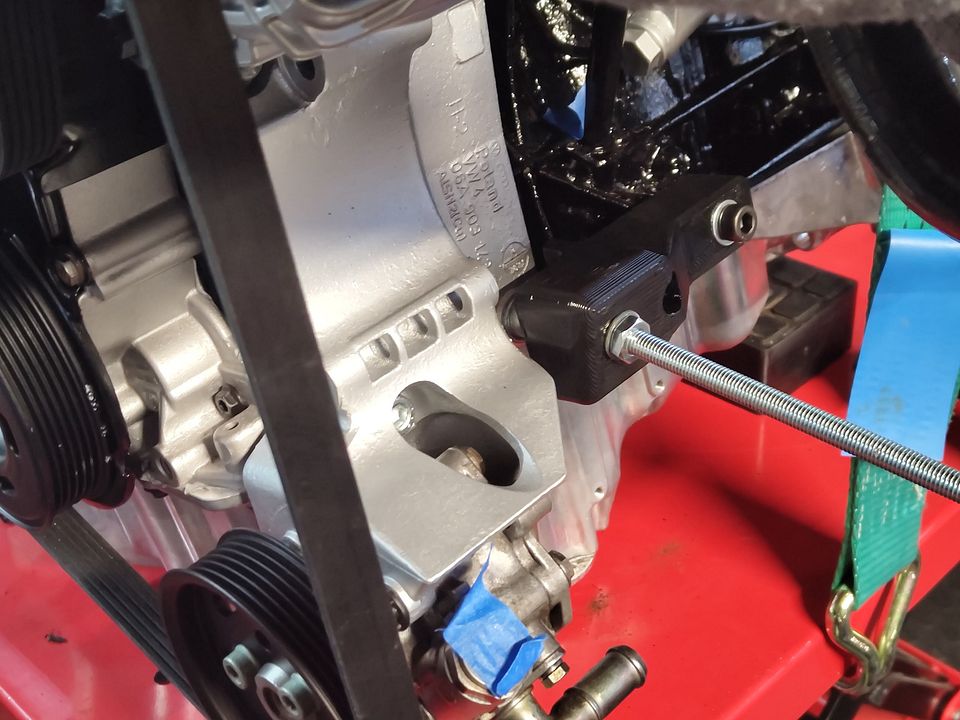

Booster Charge Cooler Bracket - this supports the entire charge cooler assembly, printed in high temp PETG:

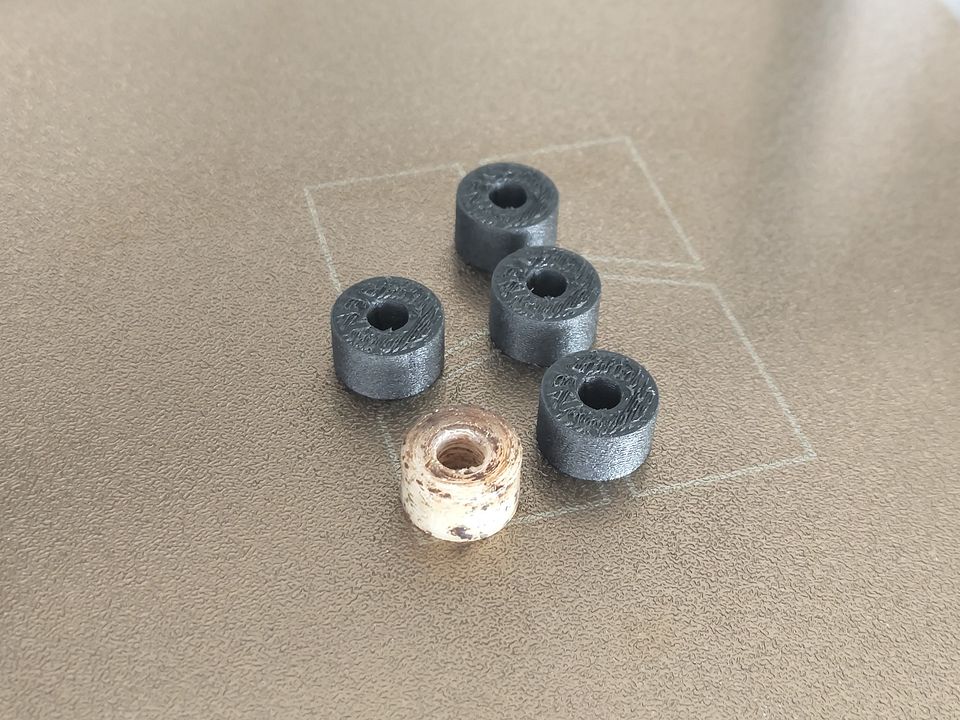

Porsche 930 Turbo oil line spacers - printed in Nylon:

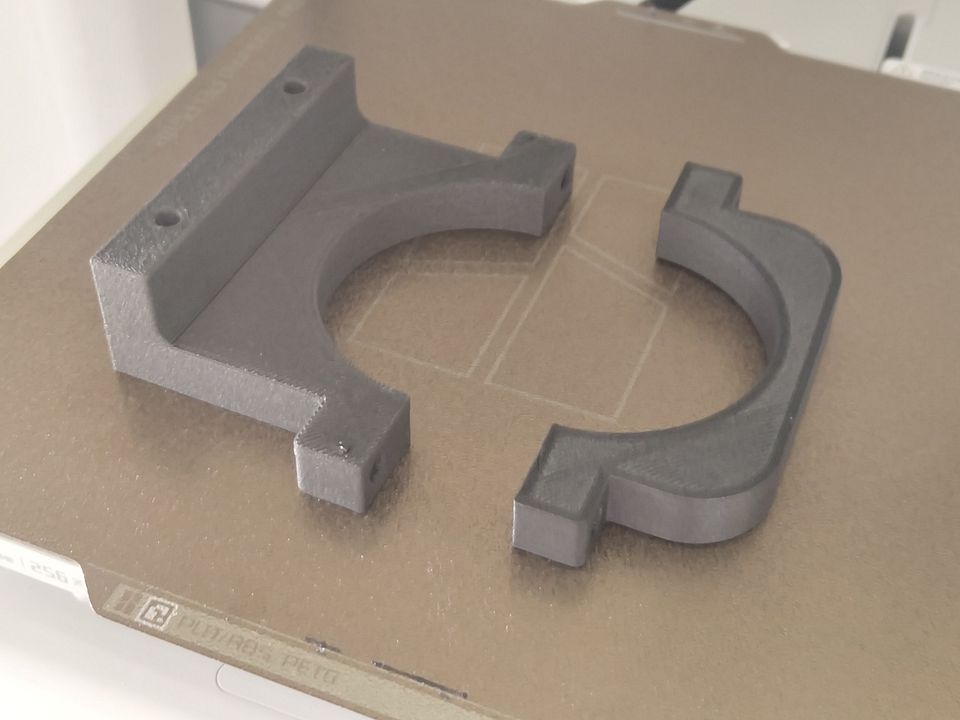

Booster Charge Cooler Header Tank Mount - printed in CF PETG:

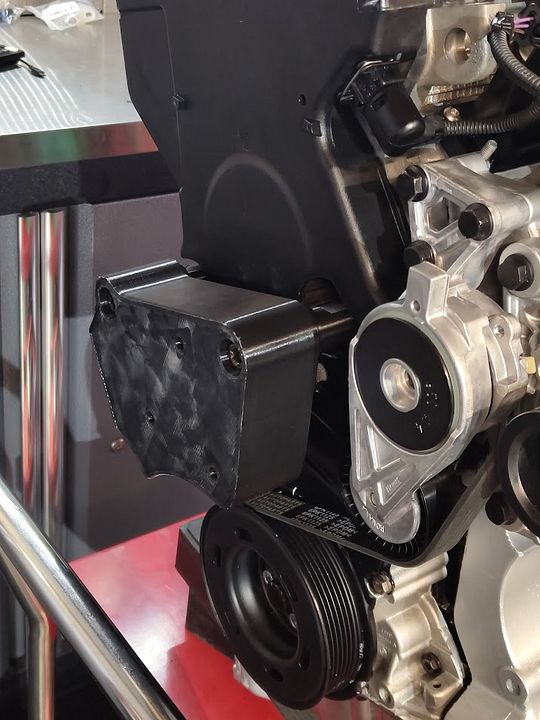

And fitted, although I think this is a test fit/mock up print:

Engine cover blisters, printed in high temp PETG and bonded to the original glass reinforced nylon cover:

ECU Mount, printed in boggo PETG:

Also extremely useful for making mockup parts before machining to test fit, geometry, clerances etc. The nice thing about designing for 3D print is that you're working from a flat surface so very similar to designing for 3 axis machining and vice versa.

Front engine mount mock up print:

If you can already use CAD and have a bit of machining experience then 3D printers are an incredibly useful tool! I can't imagine not having one.

fasimew said:

I haven't used one, but a bambu labs printer would be where my money's at if I had to buy one. Anything lesser is just a waste of time.

I've spent countless hours and a few quid in upgrades trying to get an older Prusa to print correctly. It rarely gets used, it's slow, and it can be a pain in the arse... but it's invaluable when I need it. I mainly use it for car parts, tools and things that require dimensional accuracy.

They are essentially a prototyping tool, and the finished results look and feel like it. They don't have the same finish as an injection moulded part and I think they're wasted on printing little nik naks for the home.

Different people have different requirements from their prints or prototypes.I've spent countless hours and a few quid in upgrades trying to get an older Prusa to print correctly. It rarely gets used, it's slow, and it can be a pain in the arse... but it's invaluable when I need it. I mainly use it for car parts, tools and things that require dimensional accuracy.

They are essentially a prototyping tool, and the finished results look and feel like it. They don't have the same finish as an injection moulded part and I think they're wasted on printing little nik naks for the home.

Edited by fasimew on Monday 15th July 20:50

I know what my cheap comedy printer can do, and I can use that for varous things.

At a different point on the scale, a mate is making good money printing and selling a product which looks quite pretty and professional.

It's about matching the tools and the process to the 'requirement'.

It's also about designing your 'part' or 'product' to be made with the limits of your process, and still satisfy the customer or requirement.

I could buy a £500 3D printer that would for example print better threaded holes, or I can run an HSS tap through the prints I make on a comedy chinese printer. An HSS tap is maybe a tenner.

I could invest in printing strong plastic, or I can design around the snot I use, and have a thread steel bar providing tensile strength in another example.

I might say sod it, this is a job for bashing some metal or laminating some carbon fibre instead...

beambeam1 said:

My friend does. He's printing a lot of refined brackets for E46 M3 rear bumpers for better alignment as the OEM ones are terrible.

OutInTheShed said:

Yes people do, but they tend to be using fairly good printers and have done a lot of learning.

poppopbangbang said:

I do, the answer regarding strength is yes, no, maybe, sometimes - it depends entirely on what the original part was made off and/or if you are designing specifically for 3D Print.

I use a lot of PETG for parts, usually high temp or carbon reinforced (note this is different to the CF powder matt look stuff), ABS and Nylon is also very suitable for automotive parts. PLA and similar very much not.

Thanks chaps, very interesting! My late FIL had one, but he just seemed to make toys and nick-nacks, good to know that you can make useful things with consumer grade kit!I use a lot of PETG for parts, usually high temp or carbon reinforced (note this is different to the CF powder matt look stuff), ABS and Nylon is also very suitable for automotive parts. PLA and similar very much not.

OutInTheShed said:

fasimew said:

I haven't used one, but a bambu labs printer would be where my money's at if I had to buy one. Anything lesser is just a waste of time.

I've spent countless hours and a few quid in upgrades trying to get an older Prusa to print correctly. It rarely gets used, it's slow, and it can be a pain in the arse... but it's invaluable when I need it. I mainly use it for car parts, tools and things that require dimensional accuracy.

They are essentially a prototyping tool, and the finished results look and feel like it. They don't have the same finish as an injection moulded part and I think they're wasted on printing little nik naks for the home.

Different people have different requirements from their prints or prototypes.I've spent countless hours and a few quid in upgrades trying to get an older Prusa to print correctly. It rarely gets used, it's slow, and it can be a pain in the arse... but it's invaluable when I need it. I mainly use it for car parts, tools and things that require dimensional accuracy.

They are essentially a prototyping tool, and the finished results look and feel like it. They don't have the same finish as an injection moulded part and I think they're wasted on printing little nik naks for the home.

Edited by fasimew on Monday 15th July 20:50

I know what my cheap comedy printer can do, and I can use that for varous things.

At a different point on the scale, a mate is making good money printing and selling a product which looks quite pretty and professional.

It's about matching the tools and the process to the 'requirement'.

It's also about designing your 'part' or 'product' to be made with the limits of your process, and still satisfy the customer or requirement.

I could buy a £500 3D printer that would for example print better threaded holes, or I can run an HSS tap through the prints I make on a comedy chinese printer. An HSS tap is maybe a tenner.

I could invest in printing strong plastic, or I can design around the snot I use, and have a thread steel bar providing tensile strength in another example.

I might say sod it, this is a job for bashing some metal or laminating some carbon fibre instead...

t out of my half decent not-so-cheap-and-comedy printer. It's not worth the aggro if you value your time. You'll be reaching for a hammer when you find out your multicoloured pikachu butt plug looks and feels like it came out of a knock off poundland Christmas cracker.

t out of my half decent not-so-cheap-and-comedy printer. It's not worth the aggro if you value your time. You'll be reaching for a hammer when you find out your multicoloured pikachu butt plug looks and feels like it came out of a knock off poundland Christmas cracker. OutInTheShed said:

durbster said:

I....

The only issue I've found is that I'm wondering how I can solve every problem I see around the house by printing something......

I'm now seeing prjects which might be a lot easier with a CNC router...The only issue I've found is that I'm wondering how I can solve every problem I see around the house by printing something......

There are some interesting CNC router/laser cutter things on ebay.

Gassing Station | Computers, Gadgets & Stuff | Top of Page | What's New | My Stuff