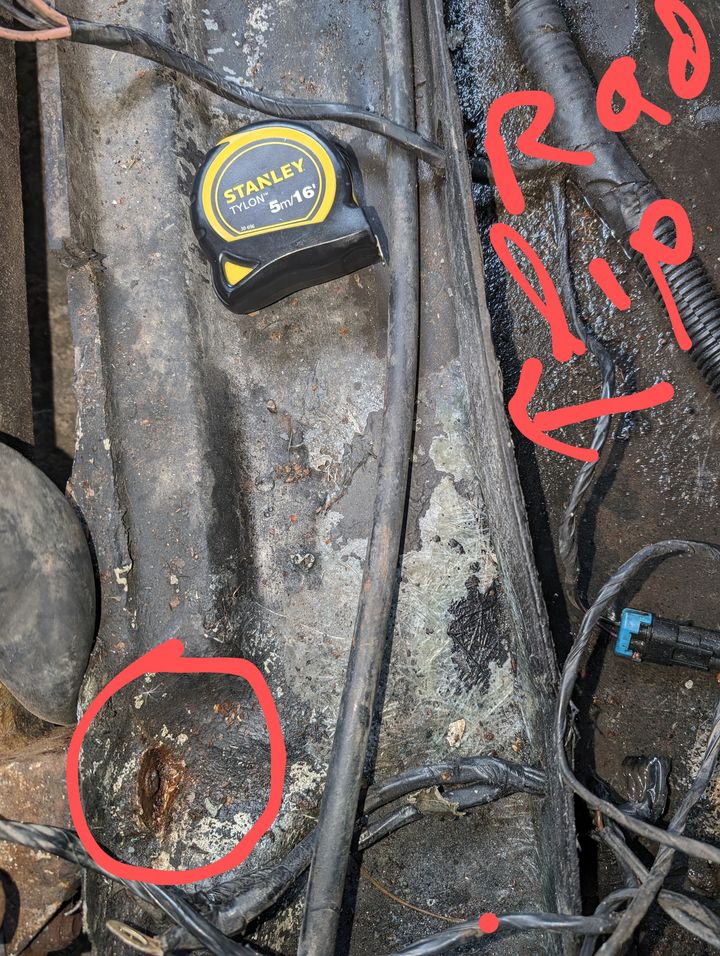

Earth bolt under Rad snapped....

Discussion

Hi everyone,

Despite me hitting the bolt with a hammer before attempting to loosen it (something a mechanic once taught me to "shock" the threads) the head on that 17mm bolt under the rad came clean off

I think drilling and tapping another thread will be a right PITA given where it is - has this happened to anyone else?

Where else could I earth those two fairly beefy wires with the ring connectors? (Which were very very rusty by the way)

Despite me hitting the bolt with a hammer before attempting to loosen it (something a mechanic once taught me to "shock" the threads) the head on that 17mm bolt under the rad came clean off

I think drilling and tapping another thread will be a right PITA given where it is - has this happened to anyone else?

Where else could I earth those two fairly beefy wires with the ring connectors? (Which were very very rusty by the way)

Cheers people. I was thinking about using the lower anti roll bar bolt as home for those two fat earth ring connectors, but if I have to tap a new thread on the original bolt so the body stays on (!) I may as well just use the original point under that rad.

The bolt (and earth connections) were totally rotten. Using penetrating oil (I usually use GT85 or plusgas) *sometimes* works for a heavily rusted bolt, but in my experience not always - I've found a good sharp whack with a hammer (sometimes using a metal bar if space is tight) to be more effective.

But yes, the position as an earthing point is questionable given it's basically under the rad and in a water trap- the ring connectors only "just" reach to that bolt, so if a better location is an option, the ring connectors will need to be extended.

Mine is a MK2 with the middle bar across the grill, so going in from the front (so to speak ) won't be an option - also, there is a fiberglass lip on the bottom (for the rad) which would prevent "front entry" anyway - and the "tradesman's entrance" isn't an option either ...

) won't be an option - also, there is a fiberglass lip on the bottom (for the rad) which would prevent "front entry" anyway - and the "tradesman's entrance" isn't an option either ...

I'll get my coat

The bolt (and earth connections) were totally rotten. Using penetrating oil (I usually use GT85 or plusgas) *sometimes* works for a heavily rusted bolt, but in my experience not always - I've found a good sharp whack with a hammer (sometimes using a metal bar if space is tight) to be more effective.

But yes, the position as an earthing point is questionable given it's basically under the rad and in a water trap- the ring connectors only "just" reach to that bolt, so if a better location is an option, the ring connectors will need to be extended.

Mine is a MK2 with the middle bar across the grill, so going in from the front (so to speak

) won't be an option - also, there is a fiberglass lip on the bottom (for the rad) which would prevent "front entry" anyway - and the "tradesman's entrance" isn't an option either ...

) won't be an option - also, there is a fiberglass lip on the bottom (for the rad) which would prevent "front entry" anyway - and the "tradesman's entrance" isn't an option either ...I'll get my coat

Many thanks for the replies everyone - they provide a glimmer of hope. The tricky thing is that bolt is only literally 1.5 possibly 2cm off the bottom of the radiator floor, making going in with a drill straight and true tricky unless I can find a drill with a very thin casing meaning I could use it on its side or possibly upside down - this would mean cutting out a section of the radiator lip to make room the drill. The excellent idea of one of those side/right angular drills may make things much easier, I might have to get one - they're cheap enough...

It will be very tight getting a grinder in there to get at what's left of the bolt. The grinder,like the sea, is a good servant but a cruel master...

It will be very tight getting a grinder in there to get at what's left of the bolt. The grinder,like the sea, is a good servant but a cruel master...

Edited by THEDAVINATOR on Tuesday 18th June 17:20

Good afternoon everyone,

I thought I'd give an update on this incase it helps anyone else...

I had an old friend come round who is very experienced with working on old cars (original minis are his thing and he's just finished building a mini sprint from scratch, so rusted bolts are not a new thing for him)

So he comes round and says "this will be no problem - get decent 3.5mm, 6.5mm and 8.5mm (for the M10 1.5 tap) drill bits and a nice new M10 tap, and I'll do it for you...

I graceously accepted his kind offer, but things didn't quite go to plan - the 6.5mm drill bit broke and I went and and got another one (all cobalt drill bits) but the drill bits either broke or barely touched the snapped bolt.

He said the bolt is extremely hard steel and recommended I just leave it as it is because the bolt is so rusted to the brass insert bush, that it ain't going anywhere.

It looks as though the brass insert bush which the bolt goes through is threaded - is this the case?

I mentioned just putting a big washer over the exposed bit of bolt and welding an "X" over the washer and (end of) bolt, but he started sucking air through his teeth and said fiberglass burns rather quickly and wouldn't risk a welder anywhere near the car...

I thought I'd give an update on this incase it helps anyone else...

I had an old friend come round who is very experienced with working on old cars (original minis are his thing and he's just finished building a mini sprint from scratch, so rusted bolts are not a new thing for him)

So he comes round and says "this will be no problem - get decent 3.5mm, 6.5mm and 8.5mm (for the M10 1.5 tap) drill bits and a nice new M10 tap, and I'll do it for you...

I graceously accepted his kind offer, but things didn't quite go to plan - the 6.5mm drill bit broke and I went and and got another one (all cobalt drill bits) but the drill bits either broke or barely touched the snapped bolt.

He said the bolt is extremely hard steel and recommended I just leave it as it is because the bolt is so rusted to the brass insert bush, that it ain't going anywhere.

It looks as though the brass insert bush which the bolt goes through is threaded - is this the case?

I mentioned just putting a big washer over the exposed bit of bolt and welding an "X" over the washer and (end of) bolt, but he started sucking air through his teeth and said fiberglass burns rather quickly and wouldn't risk a welder anywhere near the car...

Once again, many thanks everyone - the TVR community is absolutely fantastic - this has to be most friendly and helpful car communities out there.

Before I admit defeat, (and get a TVR specialist involved) I'll try and expand the 3.5mm bore that's already there with drill bits of smaller increments than my friend used - July is always a really quiet time for me work wise, so time isn't an issue for me at the moment. I think perhaps he lacked motivation to do the job because, well, it's not his car...

One method of removing rusted bolts that I've had some success with in the past is drilling a fairly hefty size hole in the bolt (at least 3/4 the diameter of bolt, preferably more) and hitting the outer shell of the existing bolt inwards with a screwdriver etc, this sometimes (if you're lucky) collapses the bolt and you can pull the bits out with needle nose pliers - this removes the need for a tap, if you're lucky...

I guess I want to keep the body lifts etc as an absolute last resort - I don't want to open another can of worms - I think on an old TVR, even the worms have their own little cans of worms

Before I admit defeat, (and get a TVR specialist involved) I'll try and expand the 3.5mm bore that's already there with drill bits of smaller increments than my friend used - July is always a really quiet time for me work wise, so time isn't an issue for me at the moment. I think perhaps he lacked motivation to do the job because, well, it's not his car...

One method of removing rusted bolts that I've had some success with in the past is drilling a fairly hefty size hole in the bolt (at least 3/4 the diameter of bolt, preferably more) and hitting the outer shell of the existing bolt inwards with a screwdriver etc, this sometimes (if you're lucky) collapses the bolt and you can pull the bits out with needle nose pliers - this removes the need for a tap, if you're lucky...

I guess I want to keep the body lifts etc as an absolute last resort - I don't want to open another can of worms - I think on an old TVR, even the worms have their own little cans of worms

I do have a pretty big mig welder and know how to weld to an acceptable standard (I learnt to weld because I had an old X1/9 years ago - it was the best welding practice there is  ) and I'm not afraid of wheeling it out (making sure there's a bucket of water and a fire extinguisher close by) but what would be the be the best thing to do with it? Just weld a washer on the end of the bolt and leave it at that?

) and I'm not afraid of wheeling it out (making sure there's a bucket of water and a fire extinguisher close by) but what would be the be the best thing to do with it? Just weld a washer on the end of the bolt and leave it at that?

) and I'm not afraid of wheeling it out (making sure there's a bucket of water and a fire extinguisher close by) but what would be the be the best thing to do with it? Just weld a washer on the end of the bolt and leave it at that?

) and I'm not afraid of wheeling it out (making sure there's a bucket of water and a fire extinguisher close by) but what would be the be the best thing to do with it? Just weld a washer on the end of the bolt and leave it at that?I've already moved the earth cables to the lower anti roll bar bolt - these bolts came undone without any trouble, I've made and extension using 3 X 30 amp wires with ring connectors from the existing earth wires to the lower anti roll bar bolt... If I can get the old bolt out, I'll put it back to how TVR intended.

Gassing Station | Chimaera | Top of Page | What's New | My Stuff

thanks for the heads up, I was going to leave it! (For now) Well then the only thing to do is somehow drill and tap a new thread - which is going to be absolute murder

thanks for the heads up, I was going to leave it! (For now) Well then the only thing to do is somehow drill and tap a new thread - which is going to be absolute murder