n57 bad rattle, rod bearings?

Discussion

Girlfriend just came home saying her car is rattling. It does not sound good.

Strangely, I have been doing a lot of reading about BMW rod bearings, particularly in the V8s - I have a car with an S63tu that I'm thinking of keeping hold of for longer than I thought.

My thoughts are that there is a high chance that this is rod bearing failure here. What do you think? I have done a very basic test of unplugging a few injectors (one at a time of course) to compare the current rough-running to a cylinder-down rough running. I just did the front 3 cylinders though due to not being in a position for stripping bits down yet, but I confirmed they are running and that engine is even worse with each of those injectors unplugged.

Video:

I suppose my options are to get whatever tool is required for pulling an injector, and putting a borescope down each cylinder to have a look from the top, and/or pulling the sump and checking the con rod bearings from the bottom.

cheers,

Carl

Strangely, I have been doing a lot of reading about BMW rod bearings, particularly in the V8s - I have a car with an S63tu that I'm thinking of keeping hold of for longer than I thought.

My thoughts are that there is a high chance that this is rod bearing failure here. What do you think? I have done a very basic test of unplugging a few injectors (one at a time of course) to compare the current rough-running to a cylinder-down rough running. I just did the front 3 cylinders though due to not being in a position for stripping bits down yet, but I confirmed they are running and that engine is even worse with each of those injectors unplugged.

Video:

I suppose my options are to get whatever tool is required for pulling an injector, and putting a borescope down each cylinder to have a look from the top, and/or pulling the sump and checking the con rod bearings from the bottom.

cheers,

Carl

Oh no...

Mine started doing exactly the same yesterday. It started out with a vibration under full load going up a long incline. I was able to drive it 20miles back home, but the noise got worse and worse.

It has code 2A6900 - Cylinder 5 Contribution / Balance - "The correction quantity is in the impermissible range."

What I did so far:

- pulled oil filter - couldn't see any glitter or similar. I also drained the oil, nothing obvious there either.

- switched injector 4 and 5 position (incl. changing the adaptation codes) to rule out it's an injector. No change, same noise and same code after this.

Initially the noise was there only at higher RPM (>1,500rpm), but now it's all there all the time.

I'm not sure what else it could be other than bottom end?

Mine started doing exactly the same yesterday. It started out with a vibration under full load going up a long incline. I was able to drive it 20miles back home, but the noise got worse and worse.

It has code 2A6900 - Cylinder 5 Contribution / Balance - "The correction quantity is in the impermissible range."

What I did so far:

- pulled oil filter - couldn't see any glitter or similar. I also drained the oil, nothing obvious there either.

- switched injector 4 and 5 position (incl. changing the adaptation codes) to rule out it's an injector. No change, same noise and same code after this.

Initially the noise was there only at higher RPM (>1,500rpm), but now it's all there all the time.

I'm not sure what else it could be other than bottom end?

Check the crank pulley before condemning the engine block. The rubber vibration damper part tends to tear apart (well documented failure item) and causes an extreme harmonic that usually wrecks main bearing no.1 first. If that spins, then the oil feed to rod bearings gets blocked, then it's Adios, muchachos.

I've decided to drop the subframe, take off the oil pan and look at it from below. Hopefully it's just a spun rod bearing and I can get away with replacing that and polishing the crank bearing surface.

Given I'm observing consistent codes for cylinder 5 balance only, I assume most likely it's that rod bearing rather than the pulley / cylinder 1. But we shall see! I'll take it apart this weekend.

Given I'm observing consistent codes for cylinder 5 balance only, I assume most likely it's that rod bearing rather than the pulley / cylinder 1. But we shall see! I'll take it apart this weekend.

marcelN57 said:

I've decided to drop the subframe, take off the oil pan and look at it from below. Hopefully it's just a spun rod bearing and I can get away with replacing that and polishing the crank bearing surface.

Given I'm observing consistent codes for cylinder 5 balance only, I assume most likely it's that rod bearing rather than the pulley / cylinder 1. But we shall see! I'll take it apart this weekend.

Good luck. I have been contemplating the same, however I'm considering just removing the engine and taking my time, after I have checked the oil and oil filter, which will be this weekend.Given I'm observing consistent codes for cylinder 5 balance only, I assume most likely it's that rod bearing rather than the pulley / cylinder 1. But we shall see! I'll take it apart this weekend.

Thanks everyone. Apologies for the radio-silence. I have been frantically getting the stationary M6 road legal and MOTd while she drives my 125d and I talk my way out of work site-visits.

It's been a wonderful week for working on a car outside and being forced to ride motorcycle a couple of times. I feel like I've had a proper holiday from my life of working and endlessly watching people do stuff on youtube. I've been forced and kicked up the arse to do my long term project (get mill running to fix lathe top slide to skim m6 discs). Refitting the cats on the M6 was a crap job as usual and that is the last time I will ever do that job.

I should hopefully start looking at the x4 this weekend.

It's been a wonderful week for working on a car outside and being forced to ride motorcycle a couple of times. I feel like I've had a proper holiday from my life of working and endlessly watching people do stuff on youtube. I've been forced and kicked up the arse to do my long term project (get mill running to fix lathe top slide to skim m6 discs). Refitting the cats on the M6 was a crap job as usual and that is the last time I will ever do that job.

I should hopefully start looking at the x4 this weekend.

That's f ked.

ked.

The problem with the N57 is that the block goes out of shape after a major trauma. If No.1 main bearing has spun, the block and crank are both scrap. Big end failure also means a piston has been touching the valves on that cylinder.

I'd be looking for another engine. The N57 is a bit marginal - disappointing after the previous M57 that was a tough old beast and hard to kill. The 35d/40d seem far more prone to this sort of thing - a regular 530d N57 is generally good for highish miles if decently treated and maintained.

ked.

ked.The problem with the N57 is that the block goes out of shape after a major trauma. If No.1 main bearing has spun, the block and crank are both scrap. Big end failure also means a piston has been touching the valves on that cylinder.

I'd be looking for another engine. The N57 is a bit marginal - disappointing after the previous M57 that was a tough old beast and hard to kill. The 35d/40d seem far more prone to this sort of thing - a regular 530d N57 is generally good for highish miles if decently treated and maintained.

The Conflated Outlier said:

That's f ked.

ked.

The problem with the N57 is that the block goes out of shape after a major trauma. If No.1 main bearing has spun, the block and crank are both scrap. Big end failure also means a piston has been touching the valves on that cylinder.

I'd be looking for another engine. The N57 is a bit marginal - disappointing after the previous M57 that was a tough old beast and hard to kill. The 35d/40d seem far more prone to this sort of thing - a regular 530d N57 is generally good for highish miles if decently treated and maintained.

Yup. N57s cannot be saved cost effectively unless the damage is very minor. The upper bearing shells being sputtered destroy the crank if they spin and BMW will bend you over £5K just for one of those. ked.

ked.The problem with the N57 is that the block goes out of shape after a major trauma. If No.1 main bearing has spun, the block and crank are both scrap. Big end failure also means a piston has been touching the valves on that cylinder.

I'd be looking for another engine. The N57 is a bit marginal - disappointing after the previous M57 that was a tough old beast and hard to kill. The 35d/40d seem far more prone to this sort of thing - a regular 530d N57 is generally good for highish miles if decently treated and maintained.

And the aluminium block warps easily from the heat of said bearing spinnage, and BMW will hammer your wallet £10K for a short motor, or £14k for a long block.

And yep again, 40 and 50d engines are borderline from the factory, in spite of the 40 and 50d cranks being a lot stronger than the base N57 single turbo's.

35ds can last if looked after and not remapped. N57 30d is the pick of the crop if lifespan is more important than performance. They go on forever if left standard with regular oil changes. i.e not BMW's 18K/24 month regime.

The M57 is the 2JZ of the diesel world, like the Merc OM6, but progress and cost cutting killed those off unfortunately.

Edited by rottenegg on Friday 3rd May 20:29

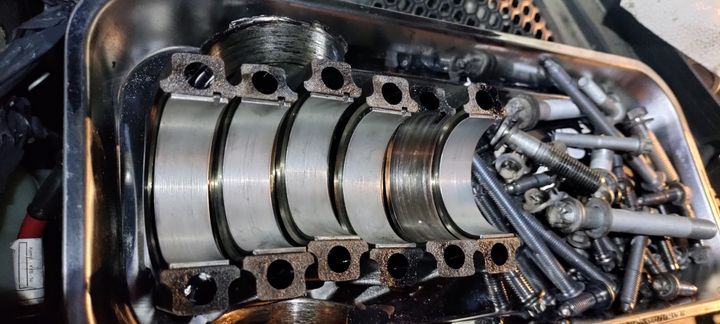

Here is how mine looks like:

1. Rod bearings - number 5 is spun and pretty destroyed. Rod and rod cap look fairly okay.

i.postimg.cc

0NJKfmqZ

IMG-20240503-213616.jpg

2. Main bearings - number 6 has lots of wear and is somewhat distorted. It was also very slightly rotated when I took them out, maybe 3-5 degree, but not so much that it would block the oil flow. It doesn't look like it spun, the outer bearing surfaces look pristine.

Number 2 to 6 are visible in the photo below.

i.postimg.cc

mDfz6DL4

IMG-20240504-190902.jpg

(can't post any photos/links here as a new forum member, if you put slashes / between the three lines you get to the photos)

No other apparent damage - pistons and cylinder surfaces look OK from what I can see from below. The oil pump had some carnage from the rod bearing in the pickup tube.

I'll try to measure run out of the crank on position 6 tomorrow. If that is acceptable, my plan is to replace all the bearings and put it back together.

Thoughts?

1. Rod bearings - number 5 is spun and pretty destroyed. Rod and rod cap look fairly okay.

i.postimg.cc

0NJKfmqZ

IMG-20240503-213616.jpg

2. Main bearings - number 6 has lots of wear and is somewhat distorted. It was also very slightly rotated when I took them out, maybe 3-5 degree, but not so much that it would block the oil flow. It doesn't look like it spun, the outer bearing surfaces look pristine.

Number 2 to 6 are visible in the photo below.

i.postimg.cc

mDfz6DL4

IMG-20240504-190902.jpg

(can't post any photos/links here as a new forum member, if you put slashes / between the three lines you get to the photos)

No other apparent damage - pistons and cylinder surfaces look OK from what I can see from below. The oil pump had some carnage from the rod bearing in the pickup tube.

I'll try to measure run out of the crank on position 6 tomorrow. If that is acceptable, my plan is to replace all the bearings and put it back together.

Thoughts?

Marcel, I will re-post your images for you.

Also, can you give a brief rundown re: dropping subframe - any shortcuts etc. The weather has picked up, so think I will do the same tomorrow. Not sure if yours in an X3/X4 too but would like to hear your experience regardless. I was going to remove bumper and pull engine but it would be good to inspect from below first.

These are MarcelN57's images:

1. Rod bearings - number 5 is spun and pretty destroyed. Rod and rod cap look fairly okay.

2. Main bearings - number 6 has lots of wear and is somewhat distorted. It was also very slightly rotated when I took them out, maybe 3-5 degree, but not so much that it would block the oil flow. It doesn't look like it spun, the outer bearing surfaces look pristine.

Number 2 to 6 are visible in the photo below.

Also, can you give a brief rundown re: dropping subframe - any shortcuts etc. The weather has picked up, so think I will do the same tomorrow. Not sure if yours in an X3/X4 too but would like to hear your experience regardless. I was going to remove bumper and pull engine but it would be good to inspect from below first.

These are MarcelN57's images:

1. Rod bearings - number 5 is spun and pretty destroyed. Rod and rod cap look fairly okay.

2. Main bearings - number 6 has lots of wear and is somewhat distorted. It was also very slightly rotated when I took them out, maybe 3-5 degree, but not so much that it would block the oil flow. It doesn't look like it spun, the outer bearing surfaces look pristine.

Number 2 to 6 are visible in the photo below.

Thank you for posting my photos, Carl!

Sure I'm happy to share a bit more how I did it.

I'm working on a F15 X5 (US version - may have some additional hoses and stuff for a 2nd EGR cooler, and the SCR/adblue system, but otherwise same as Europe version)

potential "short cuts":

- use load straps to hang the engine. I didn't have the proper engine bridge tool so that saved me time and money getting one

- tied away the steering rack and stabilizer instead of disconnecting. Stabilizer is the adaptive version so has hydraulic lines going to it.

- leave the axles in the wheel bearing / mount, just pull them out of the diff and tie away

- so far I got away with not removing / fully unbolting the power steering pump. I only removed the lowest bolt that goes directly into the oil pan. But it was very tight, I'm not sure I'll get the oil pan back on with the pump still in place.

Some pictures below (grateful if you can repost).

View from above on all the straps that hold the engine (engine mount) as well as steering rack and stabilizer in place

i.postimg.cc (slash) kDrq6Zg9 (slash) IMG-20240502-165612.jpg

Sub frame just coming down. It's not too heavy, I did all of this by myself.

i.postimg.cc (slash) KYVMpG95 (slash) IMG-20240502-180349.jpg

View from below with subframe removed

i.postimg.cc (slash) nVXmmDhw (slash) IMG-20240503-145119.jpg

Look carefully for cables / hoses tied to the subframe, there are quite a few at least on my car. I nearly ripped the wiring harness going to the steering rack apart when lowering the subframe and initially not realizing it is attached to it.

Overall, nothing really difficult but quite a number of things to remove.

Lacking alternatives, I'm doing all of this in the parking garage of an upscale apartment complex. So I have to be careful to make the scene look not too messy and always clean up, put back all the tools etc when I leave.

Good luck with yours! Curious to see what you will find.

Sure I'm happy to share a bit more how I did it.

I'm working on a F15 X5 (US version - may have some additional hoses and stuff for a 2nd EGR cooler, and the SCR/adblue system, but otherwise same as Europe version)

potential "short cuts":

- use load straps to hang the engine. I didn't have the proper engine bridge tool so that saved me time and money getting one

- tied away the steering rack and stabilizer instead of disconnecting. Stabilizer is the adaptive version so has hydraulic lines going to it.

- leave the axles in the wheel bearing / mount, just pull them out of the diff and tie away

- so far I got away with not removing / fully unbolting the power steering pump. I only removed the lowest bolt that goes directly into the oil pan. But it was very tight, I'm not sure I'll get the oil pan back on with the pump still in place.

Some pictures below (grateful if you can repost).

View from above on all the straps that hold the engine (engine mount) as well as steering rack and stabilizer in place

i.postimg.cc (slash) kDrq6Zg9 (slash) IMG-20240502-165612.jpg

Sub frame just coming down. It's not too heavy, I did all of this by myself.

i.postimg.cc (slash) KYVMpG95 (slash) IMG-20240502-180349.jpg

View from below with subframe removed

i.postimg.cc (slash) nVXmmDhw (slash) IMG-20240503-145119.jpg

Look carefully for cables / hoses tied to the subframe, there are quite a few at least on my car. I nearly ripped the wiring harness going to the steering rack apart when lowering the subframe and initially not realizing it is attached to it.

Overall, nothing really difficult but quite a number of things to remove.

Lacking alternatives, I'm doing all of this in the parking garage of an upscale apartment complex. So I have to be careful to make the scene look not too messy and always clean up, put back all the tools etc when I leave.

Good luck with yours! Curious to see what you will find.

Thanks very much! I do have an engine support bar so I can use that to help.

I've reposted your photos below.

These are MarcelN57's photos:

View from above on all the straps that hold the engine (engine mount) as well as steering rack and stabilizer in place

Sub frame just coming down. It's not too heavy, I did all of this by myself.

View from below with subframe removed

I've reposted your photos below.

These are MarcelN57's photos:

View from above on all the straps that hold the engine (engine mount) as well as steering rack and stabilizer in place

Sub frame just coming down. It's not too heavy, I did all of this by myself.

View from below with subframe removed

Now you have definite confirmation it's not an injector or something like that!

Update from my carnage:

I polished the crank surface for the #5 rod bearing (the bad one), then put that journal back together using the bearing shells from one of the other (good) rods. The plan was to measure the bearing clearance with Plastigage. However - the journal had lots and lots of play. Knock knock

So I took it back apart and measured the crank diameter at #5 rod position. It's between 49.2 and 49.5mm depending where you measure - not round and totally out of spec (49.975 - 49.994)!

Sounds like I need a new crankshaft. Which means, I need to take the engine out. At that point, it also makes sense to replace the #5 connecting rod. Which means, head has to come off... Gone the dream of a quick fix for this.

Update from my carnage:

I polished the crank surface for the #5 rod bearing (the bad one), then put that journal back together using the bearing shells from one of the other (good) rods. The plan was to measure the bearing clearance with Plastigage. However - the journal had lots and lots of play. Knock knock

So I took it back apart and measured the crank diameter at #5 rod position. It's between 49.2 and 49.5mm depending where you measure - not round and totally out of spec (49.975 - 49.994)!

Sounds like I need a new crankshaft. Which means, I need to take the engine out. At that point, it also makes sense to replace the #5 connecting rod. Which means, head has to come off... Gone the dream of a quick fix for this.

marcelN57 said:

Now you have definite confirmation it's not an injector or something like that!

Update from my carnage:

I polished the crank surface for the #5 rod bearing (the bad one), then put that journal back together using the bearing shells from one of the other (good) rods. The plan was to measure the bearing clearance with Plastigage. However - the journal had lots and lots of play. Knock knock

So I took it back apart and measured the crank diameter at #5 rod position. It's between 49.2 and 49.5mm depending where you measure - not round and totally out of spec (49.975 - 49.994)!

Sounds like I need a new crankshaft. Which means, I need to take the engine out. At that point, it also makes sense to replace the #5 connecting rod. Which means, head has to come off... Gone the dream of a quick fix for this.

Oh dear, I'm sorry to hear that. I was hoping you (and I!) would get away with a quick fix.Update from my carnage:

I polished the crank surface for the #5 rod bearing (the bad one), then put that journal back together using the bearing shells from one of the other (good) rods. The plan was to measure the bearing clearance with Plastigage. However - the journal had lots and lots of play. Knock knock

So I took it back apart and measured the crank diameter at #5 rod position. It's between 49.2 and 49.5mm depending where you measure - not round and totally out of spec (49.975 - 49.994)!

Sounds like I need a new crankshaft. Which means, I need to take the engine out. At that point, it also makes sense to replace the #5 connecting rod. Which means, head has to come off... Gone the dream of a quick fix for this.

I pulled pan on mine, oil was like black gloop. When I washed away the gloopy oil in the pan, I saw lots of beautiful glitter.

You can get a new forged crank from Autodoc for ~$1200 USD. Non-OEM but also not Aliexpress. You can also get one from Ali Express for half that :-) that won't be forged though.

Do you know of anyone who has experience with the aftermarket crankshafts?

I'm a little nervous going for the aftermarket ones given how much work the replacement is, and how relatively little difference it makes in overall cost for the repair.

I can get an OEM new crank here for $1700 + shipping, maybe $1850 total. The aftermarket forged ones will be $1200, not that much cheaper - given I will also need about another $1000 in various other parts like bearings, bolts, gaskets, etc

Which raises another point - realistically repairing this is going to cost $3,000 in parts, and many hours of work. I like the car and don't really want to scrap it and get another one. I'm also enjoying doing the work, even though it's a big unexpected job now.

However, will the repair last? Why did the rod bearing spin in the first place?

I've inspected the #6 main in detail and am confident that it didn't spin. As this one supplies the #5 rod with oil, it would have been a very clear progression if it started there. But it really doesn't look like it.

So then, the damage started with the rod #5, that started to spin + knock, and then that caused the substantial wear on #6 main? The other rod bearings all look pretty, so why did the #5 rod journal go bad? Just random bad luck? What will happen next to this engine? ...

Good luck! Enjoy the glitter

I'm a little nervous going for the aftermarket ones given how much work the replacement is, and how relatively little difference it makes in overall cost for the repair.

I can get an OEM new crank here for $1700 + shipping, maybe $1850 total. The aftermarket forged ones will be $1200, not that much cheaper - given I will also need about another $1000 in various other parts like bearings, bolts, gaskets, etc

Which raises another point - realistically repairing this is going to cost $3,000 in parts, and many hours of work. I like the car and don't really want to scrap it and get another one. I'm also enjoying doing the work, even though it's a big unexpected job now.

However, will the repair last? Why did the rod bearing spin in the first place?

I've inspected the #6 main in detail and am confident that it didn't spin. As this one supplies the #5 rod with oil, it would have been a very clear progression if it started there. But it really doesn't look like it.

So then, the damage started with the rod #5, that started to spin + knock, and then that caused the substantial wear on #6 main? The other rod bearings all look pretty, so why did the #5 rod journal go bad? Just random bad luck? What will happen next to this engine? ...

Good luck! Enjoy the glitter

Gassing Station | BMW General | Top of Page | What's New | My Stuff