DB11 V12 Evaporative Emissions System

Discussion

Over the last several days, I've completely rebuilt the evaporative emissions system in my 2018 DB11 V12. My mission was to replace all components in the system without any visit to an AM dealer.

I did this because I was occasionally (about every 100 miles which is a typical EMS system check) receiving a CEL (a P0456), defined as a very small vapor leak. Without the proper test equipment I could not test the system to pinpoint the exact failure point so I renewed every component in the system. The ONLY component not renewed is the capless fuel fill port (what an absolutely stupid design). I had to hope some other component failed in the system as the capless unit would have to be AM parts at an exorbitant price. One other part(s) of the system that could fail is any cracked or leaking lines. These too, I did not check, but was hopeful not the problem. I would have had to use a smoke machine to test for failed lines.

First, I tackled the back end of the system which starts with the carbon canister along with a vapor leak detection pump. These are in an assembly found in the left hand rear wheel well (on a LHD NA car). It looks like this:

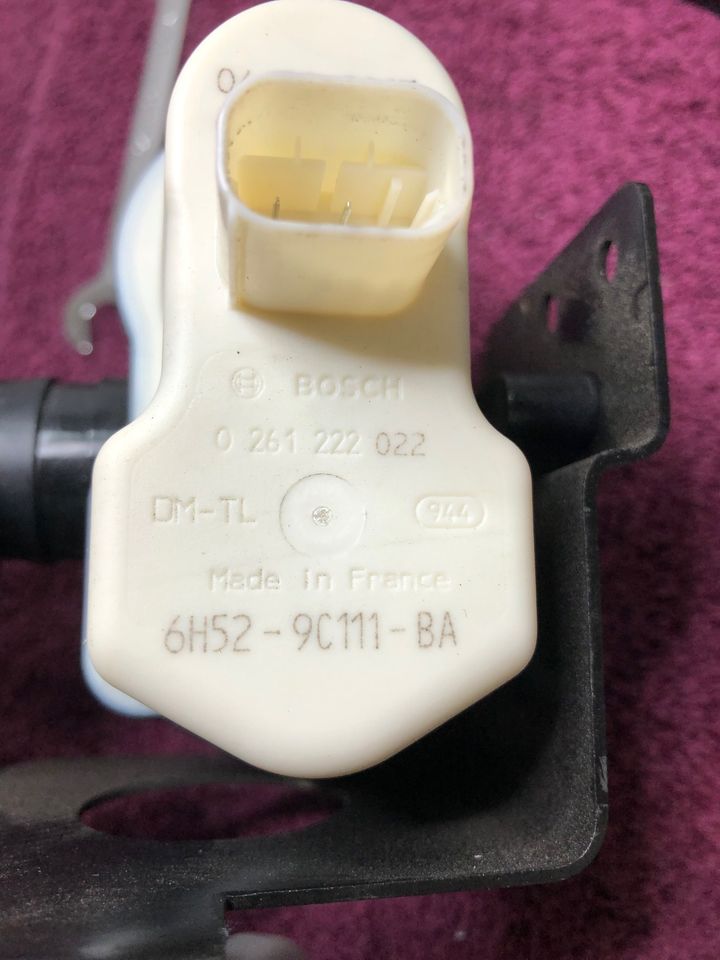

For the vapor leak detection pump, I found it to be a fairly common Bosch part easily obtainable from parts stores. This same pump is used on a number of other cars. For the carbon canister, I searched and searched but could not find the source of this part, so I elected to open the canister and rebuild it completely with new carbon material I easily found in the commercial marketplace. The canister has a "clean" and a "dirty" side separated by a spring loaded, double sided filter. The canister is divided about 1/3, 2/3rds - 2/3rd the dirty side, 1/3 the clean side. This rebuild went easily, I resealed the canister, the assembled the new pump and filter, then back in the car.

The "other" end of the evaporative emissions system is found under the bonnet. On the V12, AM used a pair of purge valves which are typical failure points in this system. The purge valves are located here:

Some disassembly has to be had to reach these two components. I won't go through those gory details, but should be intuitive from the picture. Here too, I found the purge valves to be a somewhat common Bosch component, used on a number of other cars from different manufacturers and easily acquired. I actually purchased these two purge valves on Amazon.

One last component (a pair, aft of the purge valves) is an anti-siphon (one way) valve found in the lines that leave the purge valves, and before those lines attach to the TBs. These were easily tested as any one way valve would be.

Now after this rebuild, I've put about 300 miles on the car with no more CELs, no more P0456s. Very satisfied with the results and the entire rebuild cost about $150 USD.

I did this because I was occasionally (about every 100 miles which is a typical EMS system check) receiving a CEL (a P0456), defined as a very small vapor leak. Without the proper test equipment I could not test the system to pinpoint the exact failure point so I renewed every component in the system. The ONLY component not renewed is the capless fuel fill port (what an absolutely stupid design). I had to hope some other component failed in the system as the capless unit would have to be AM parts at an exorbitant price. One other part(s) of the system that could fail is any cracked or leaking lines. These too, I did not check, but was hopeful not the problem. I would have had to use a smoke machine to test for failed lines.

First, I tackled the back end of the system which starts with the carbon canister along with a vapor leak detection pump. These are in an assembly found in the left hand rear wheel well (on a LHD NA car). It looks like this:

For the vapor leak detection pump, I found it to be a fairly common Bosch part easily obtainable from parts stores. This same pump is used on a number of other cars. For the carbon canister, I searched and searched but could not find the source of this part, so I elected to open the canister and rebuild it completely with new carbon material I easily found in the commercial marketplace. The canister has a "clean" and a "dirty" side separated by a spring loaded, double sided filter. The canister is divided about 1/3, 2/3rds - 2/3rd the dirty side, 1/3 the clean side. This rebuild went easily, I resealed the canister, the assembled the new pump and filter, then back in the car.

The "other" end of the evaporative emissions system is found under the bonnet. On the V12, AM used a pair of purge valves which are typical failure points in this system. The purge valves are located here:

Some disassembly has to be had to reach these two components. I won't go through those gory details, but should be intuitive from the picture. Here too, I found the purge valves to be a somewhat common Bosch component, used on a number of other cars from different manufacturers and easily acquired. I actually purchased these two purge valves on Amazon.

One last component (a pair, aft of the purge valves) is an anti-siphon (one way) valve found in the lines that leave the purge valves, and before those lines attach to the TBs. These were easily tested as any one way valve would be.

Now after this rebuild, I've put about 300 miles on the car with no more CELs, no more P0456s. Very satisfied with the results and the entire rebuild cost about $150 USD.

McButterpants said:

Did you have a way of reading the P code? Every code reader i try fails to read anything at all. I know that you need the AMS system to get into all the details but I just want to check for basic codes.

I've no problem reading any "power train" codes on this platform. P-codes produce the infamous CEL (check engine light). These codes are not proprietary to any auto manufacturer. Auto builders complying with US/Euro EPA emissions standards must use the SAE standard protocols and provide capability for these codes to be accessed openly. I have several scan tools, some cheap and simple and some much more complex and they all work to read P-codes on my DB11. An older scan tool wouldn't work. The scan tool must be CAN-BUS compatible but you would have to be using a tool probably back before 2006 for that to be the case. Other monitored systems on the car (and all other cars) do get proprietary. These include

B-codes - body and security faults

C-codes - chassis faults

U-codes - networking faults

Any of these faults I cannot read without an AM system, which no aftermarket suppliers support on the DB11 platform, to my knowledge.

thanks, yea not sure. I had one that was an innova that was maybe $60 and at the time i had both low voltage and misfires and it read absolutely nothing.

Now i lost that one and tried another innova $30 cheap one and again, nothing.

I am going to try a Foxwell nt530 next. Aston said it sounds like an evap issue but i made an appointment that i'll keep if the foxwell cant read it.

Now i lost that one and tried another innova $30 cheap one and again, nothing.

I am going to try a Foxwell nt530 next. Aston said it sounds like an evap issue but i made an appointment that i'll keep if the foxwell cant read it.

QUESTION: Are you getting a check engine light for misfires, etc? If you are not, then no codes are being produced to be read by a scan tool.

If the CEL is illuminated, then any recent CAN BUS scan tool should read it.

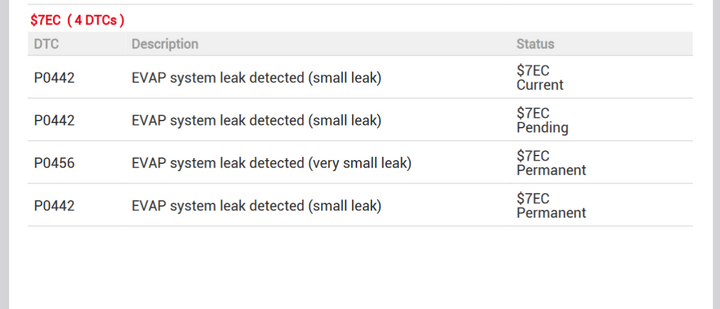

When dealing with the emissions fault described above on my DB11, I used one of my tools, an Autel MX808 and it read the following (and I deleted same codes with the delete feature which even my cheap tools have):

If the CEL is illuminated, then any recent CAN BUS scan tool should read it.

When dealing with the emissions fault described above on my DB11, I used one of my tools, an Autel MX808 and it read the following (and I deleted same codes with the delete feature which even my cheap tools have):

OP - I’m running into the same issues here… CEL comes on every 50 miles or so and the code reader shows small evap leak. Would you mind sharing the part numbers for the various valves you replaced - I believe you said all were common Bosch parts.

Also - how involved is getting to the two valves under the bonnet? I’m trying to decide if I can tackle this project myself or not :-)

Thanks!

Also - how involved is getting to the two valves under the bonnet? I’m trying to decide if I can tackle this project myself or not :-)

Thanks!

Mmayberry said:

OP - I’m running into the same issues here… CEL comes on every 50 miles or so and the code reader shows small evap leak. Would you mind sharing the part numbers for the various valves you replaced - I believe you said all were common Bosch parts.

Also - how involved is getting to the two valves under the bonnet? I’m trying to decide if I can tackle this project myself or not :-)

Thanks!

Hi Mmayberry,Also - how involved is getting to the two valves under the bonnet? I’m trying to decide if I can tackle this project myself or not :-)

Thanks!

Sorry to hear you're dealing with small leaks in the evap system. Because of regs, this system is overly complex and clumsily designed.

The first question - are you in the UK or the US (or elsewhere)? Asking because it will vary whether you can get aftermarket parts to repair.

Without going into a lot of gory detail, the way the system tests, and the frequency - Evap system is "tested" by the ECU (2) every few startups. It will do the test for leaks by and before the engine starts. Therefor, you will typically see the check engine light upon random starts. not while the engine is running.

The system checks for leaks by literally pressurizing the entire system from the fuel filler tube to the purge valves, then the electrical resistance of the pump is measured against a set value. If there are no leaks, then the resistance will be high. If there are leaks the resistance will be low. Then, of course, if the pump is faulty, it could report a leak that is not really there.

Well, enough design theory, now to the fault(s).

I began making assumptions and started replacing suspect parts in the system which is a terrible way to do this, but believe it or not, the AM factory TSB used by field techs to diagnose the very same faults does the same - starts replacing parts until the problem is solved. So, I replaced (in order)

Carbon canister

leak detection pump

then the purge valves. (2, one on each throttle body)

The purge valves are a Bosch part; HOWEVER, AM takes this valve and builds in the fore and aft lines, now making it an assembly costing hundreds of $USD. The valve(s) itself sell for anywhere from $15 to $50 USD depending on the source. It is a somewhat common purge valve used on some other cars (chevy cruze, for one). This particular Bosch purge valve appears to be common for sale in the aftermarket in the UK/EU under P/N Bosch 0280-142-442. In the US, and since not used on US cars, there are aftermarket parts with the same specs only not with the Bosch name. This is the reason why I asked for your loc.

For my creative solution, I removed the factory ASSEMBLED units then cut the lines at the purge valves (fore and aft) then spliced in the new valves to the original lines using fuel line hose and appropriate clamps. BTW, in the end, and after renewing most every part in the system except the fuel filler, I did find one of the two purge valves leaked when I did a vacuum pump test on them after replacement.

Regarding the R and R - You will need to remove the plastic cowl cover. You might also have to remove the cross brace (depends how agile you are). The cowl comes off relatively easily -

Remove both windscreen wiper arms

Remove the bonnet bumper stops (left and right)

The cowl has two plastic snap in tabs approx in the center snapping onto the cross brace. These have a strong tendency tp break BC of age, so do not fret if one or both are broken.

The cross brace (if you cannot get to both ends of two purge valves) is very easy and intuitive when the cowl is removed.

Conclusion - I cannot judge your mechanical capabilities, but if you paid for the exorbitantly expensive AM assemblies then just installed those I would rate this job as a 2.5 or 3 out of 5 difficulty. If you do the splice in aftermarket parts, then a 3 to 3.5 of 5 difficulty. And, unfortunately, if you did all of the above you still might have a P0456 or/and 442 because lines can be cracked, fuel filler could be leaking, etc. The fuel filler without an actual gas cap is another very dumb design. The filler tube alone is over $1K when a simple gas cap design could fix an evap leak with a new cap for around circa $25.

Skhannes - thank you so much for the detailed response. Extremely helpful. I am located in the US.

I was able to locate the complete purge valve assembly on the Aston Bits website for GBP100, which doesn’t seem to be too terribly much over the cost of the vales. So maybe that beats splicing in this case.

Separately, on eBay there is the canister and valve, but its used and ~$263. No way of knowing if it’s working or was also a CEL light car when it was salvaged, or if the part was submerged in a flood, etc.

I wonder if the higher end ODBII readers can test the valves individually. Im debating spending $400 and the time for a non-guaranteed fix. Hmmmm. Lots to think about.

Matt

I was able to locate the complete purge valve assembly on the Aston Bits website for GBP100, which doesn’t seem to be too terribly much over the cost of the vales. So maybe that beats splicing in this case.

Separately, on eBay there is the canister and valve, but its used and ~$263. No way of knowing if it’s working or was also a CEL light car when it was salvaged, or if the part was submerged in a flood, etc.

I wonder if the higher end ODBII readers can test the valves individually. Im debating spending $400 and the time for a non-guaranteed fix. Hmmmm. Lots to think about.

Matt

Mmayberry said:

Skhannes - thank you so much for the detailed response. Extremely helpful. I am located in the US.

I was able to locate the complete purge valve assembly on the Aston Bits website for GBP100, which doesn’t seem to be too terribly much over the cost of the vales. So maybe that beats splicing in this case.

Separately, on eBay there is the canister and valve, but its used and ~$263. No way of knowing if it’s working or was also a CEL light car when it was salvaged, or if the part was submerged in a flood, etc.

I wonder if the higher end ODBII readers can test the valves individually. Im debating spending $400 and the time for a non-guaranteed fix. Hmmmm. Lots to think about.

Matt

Hi Matt,I was able to locate the complete purge valve assembly on the Aston Bits website for GBP100, which doesn’t seem to be too terribly much over the cost of the vales. So maybe that beats splicing in this case.

Separately, on eBay there is the canister and valve, but its used and ~$263. No way of knowing if it’s working or was also a CEL light car when it was salvaged, or if the part was submerged in a flood, etc.

I wonder if the higher end ODBII readers can test the valves individually. Im debating spending $400 and the time for a non-guaranteed fix. Hmmmm. Lots to think about.

Matt

Now that I know you're in the US, there is an aftermarket purge valve and, of course, it is only the valve so splicing would be your only option. The crossover PN for the Bosch 0280142442 is also a Chinese part so all of these factors could change your mind.

If you're interested in the part it is available on Amazon, just search Amazon using the Bosch PN, this is the description for the aftermarket valve and the ones I now have in my car. I have approx. 500 + miles since changing these

0280142430 Vapor Canister Purge Valve Solenoid Valve Compaitble with Chevro let Cruze Opel Astra Corsa Insignia Part No.#0280142442/55353802 / 55574240/0280142440

Also, the way to test a purge valve is with a simple vacuum pump. Placing vacuum at the front port (the port going to the throttle body) should hold vacuum. If it does not, that valve is leaking.

All the Best!

Thank you for the continued sharing of your wealth of information. I think I’m going to buy a Foxwell NT530, which can supposedly run an evap test and tell you which part(s) are faulty. I’m a little suspicious, but feels worth a try before I rip into the car too much. I’ll post updates when available.

Mmayberry said:

Thank you for the continued sharing of your wealth of information. I think I’m going to buy a Foxwell NT530, which can supposedly run an evap test and tell you which part(s) are faulty. I’m a little suspicious, but feels worth a try before I rip into the car too much. I’ll post updates when available.

Hi Mmayberry,I would very much like to hear any info that you come up with, especially if the NT530 can do anything on the DB11 V12, past the simple engine/trans fault codes. Would be grateful!

All the Best,

Quick update here. I emailed Foxwell and they said they don’t believe any of their units can do an EVAP test on a V12 DB11. So I tried a Konnwei KW850 as it says it works with Astons and has an EVAP test function. However, no dice there either. All the standard OBD2 scans worked fine, but when I ran the EVAP test function it too said not supported. Bummer.

OP - do you have a part number on the EVAP system test pump? I believe I read that you changed that on the charcoal canister. I think my plan at this point is to replace that first, and if it doesnt fix it, go for the purge valves up front.

Thanks!

OP - do you have a part number on the EVAP system test pump? I believe I read that you changed that on the charcoal canister. I think my plan at this point is to replace that first, and if it doesnt fix it, go for the purge valves up front.

Thanks!

Yes on the leak detection pump. These are very common used on lots of cars. Just follow the Bosch # 0261222022. These are on Amazon if you like:

https://www.amazon.com/s?k=0261222022&crid=2HB...

https://www.amazon.com/s?k=0261222022&crid=2HB...

Gassing Station | Aston Martin | Top of Page | What's New | My Stuff