Mid Engine TR6060 Transaxle

Discussion

First post here, so hello everyone. I saw some similar posts when searching on google that brought me here and I saw plenty of 'goodluck buddy' feedback as well as helpful feedback from the community, and I am open to all criticism, concerns, considerations. The image below is a mockup photo I made of the build/style I'm going for.

A little background about me, I currently own 3 ATS-V (1 daily, 1 race car, 1 garage queen) (LF4 3.6L Twin Turbo) Since owning these 3 years ago, I've become quite familiar with the engine and general knowledge of the car doing most of all my current race car build (Road Course HPDE), but I am not a professional car builder. I have a shop with lift for my personal use where I do projects and have a wide range of tools and ability to learn. I am self taught with 3D modeling/rendering and have 3D printed my own custom ATS-V Aero parts, and am currently working on a full widebody kit for my race car.

Conveniently, next to my personal shop is a professional custom racing harness manufacturer. They are contracted by Ford directly to make custom wiring harness for high end performance ford builds like the Ford GT. They've helped me more than once with complex damaged wiring harnesses on my ATS-V with excellent work. I've brought this idea up to them and are willing to assist whenever I'm ready.

As the title says, my ideal build would be to make this a mid engine using all of the same Engine, Wiring, ECM, Transmission (TR6060 6 speed Manual) to mitigate the confusion.

This would require mating the stock TR6060 Transmission with a transaxle. From further research I've come across this Youtuber that used a corvette transaxle and wondering if anyone has done anything similar: https://www.youtube.com/watch?v=iMQGsrbxDFA

One thing I'm not sure of it how this could affect the driving/traction modes) by removing the rear diff for a C6+ transaxle

This is just one of the MANY obstacles in the build and I'm not expecting it to be easy to mount this in the rear,. There will need to be significant changes to the cabin/frame/mounting/shifter linkage and if anyone has experience with a similar project hope you'll share your wisdom with me here.

Thanks for reading

A little background about me, I currently own 3 ATS-V (1 daily, 1 race car, 1 garage queen) (LF4 3.6L Twin Turbo) Since owning these 3 years ago, I've become quite familiar with the engine and general knowledge of the car doing most of all my current race car build (Road Course HPDE), but I am not a professional car builder. I have a shop with lift for my personal use where I do projects and have a wide range of tools and ability to learn. I am self taught with 3D modeling/rendering and have 3D printed my own custom ATS-V Aero parts, and am currently working on a full widebody kit for my race car.

Conveniently, next to my personal shop is a professional custom racing harness manufacturer. They are contracted by Ford directly to make custom wiring harness for high end performance ford builds like the Ford GT. They've helped me more than once with complex damaged wiring harnesses on my ATS-V with excellent work. I've brought this idea up to them and are willing to assist whenever I'm ready.

As the title says, my ideal build would be to make this a mid engine using all of the same Engine, Wiring, ECM, Transmission (TR6060 6 speed Manual) to mitigate the confusion.

This would require mating the stock TR6060 Transmission with a transaxle. From further research I've come across this Youtuber that used a corvette transaxle and wondering if anyone has done anything similar: https://www.youtube.com/watch?v=iMQGsrbxDFA

One thing I'm not sure of it how this could affect the driving/traction modes) by removing the rear diff for a C6+ transaxle

This is just one of the MANY obstacles in the build and I'm not expecting it to be easy to mount this in the rear,. There will need to be significant changes to the cabin/frame/mounting/shifter linkage and if anyone has experience with a similar project hope you'll share your wisdom with me here.

Thanks for reading

Is this for a road car or race car?

If you're using the stock ECM/ABS etc that came with the car, don't expect the stability control or ABS systems to behave properly at all, you're fundamentally changing the whole layout and balance of the car.

As for the mechanical side, it sounds like the Corvette bits for the TR6060 will be perfectly suited.

If you're using the stock ECM/ABS etc that came with the car, don't expect the stability control or ABS systems to behave properly at all, you're fundamentally changing the whole layout and balance of the car.

As for the mechanical side, it sounds like the Corvette bits for the TR6060 will be perfectly suited.

Hey Krikkit, it's for road course use only. Usually when on track I'm in PTM - Race which is pretty much no TC but I do believe it stiffens the OEM mag ride. Very possible I would ditch the OEM mag ride for a custom setup later but planning on taking it in small steps and not rushing to change so many variables at once

So you'd realistically be putting the twin turbo V6 on the back seats? I can see that getting a little warm in the cabin!

As it's for track use and the size of the job, personally I can't see the point in trying to keep any original harness etc.

The interior is surely going to be gone, so ditch the whole loom, get a standalone Holley or similar to run the engine and save yourself an enormous amount of work?

I appreciate the idea of trying to do things a bit at a time, but I can't help but feel you're creating a huge amount of work for yourself trying to keep any of the factory stuff. I mean obviously it doesn't care where the engine physically is, but for the work involved loom wise (even with the nice blokes next door) it feels like making a lot of extra work for yourself...?

As it's for track use and the size of the job, personally I can't see the point in trying to keep any original harness etc.

The interior is surely going to be gone, so ditch the whole loom, get a standalone Holley or similar to run the engine and save yourself an enormous amount of work?

I appreciate the idea of trying to do things a bit at a time, but I can't help but feel you're creating a huge amount of work for yourself trying to keep any of the factory stuff. I mean obviously it doesn't care where the engine physically is, but for the work involved loom wise (even with the nice blokes next door) it feels like making a lot of extra work for yourself...?

I don't think that's going to work very well.

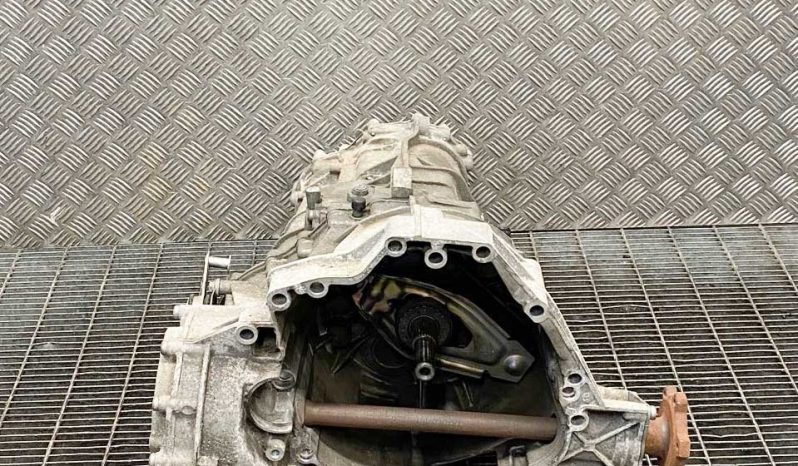

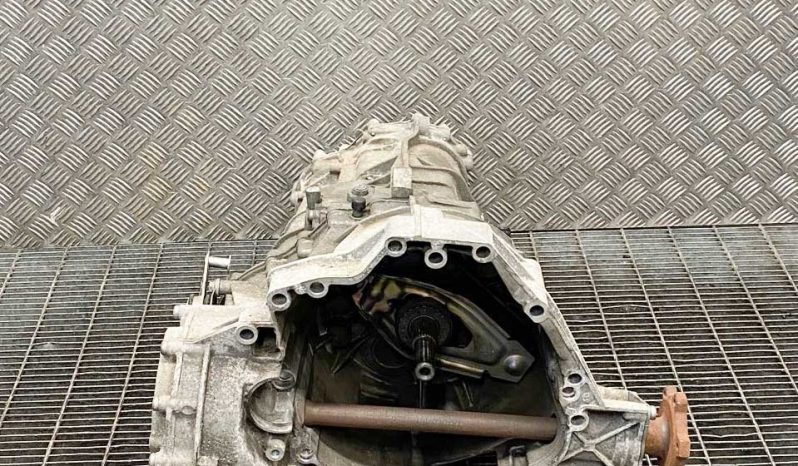

The problem you have is that the TR6060 gearbox is designed to be "inline", ie input and output are at opposite ends. Unless you want to have a massively long rear overhang then you want to have the "gearbox" behind the axle line (as pretty much everything with a mid-engine RWD does), to do that you need to have a gearbox that has input and output both on the same "end".

TR6060

The only way to do it would be kind of like this (imagine that's a TR6060 at the front)...

but look how far the output flanges on the diff are from the engine in comparison to an Audi Transaxle

The other option is to maybe hack about one of the Audi boxes that run the output shaft between clutch and engine. Take an output shaft from the rear of the TR6060, run it down the side and into the diff.

Obviously you then have the issues of the gear linkage but that's far easier to solve!

The problem you have is that the TR6060 gearbox is designed to be "inline", ie input and output are at opposite ends. Unless you want to have a massively long rear overhang then you want to have the "gearbox" behind the axle line (as pretty much everything with a mid-engine RWD does), to do that you need to have a gearbox that has input and output both on the same "end".

TR6060

The only way to do it would be kind of like this (imagine that's a TR6060 at the front)...

but look how far the output flanges on the diff are from the engine in comparison to an Audi Transaxle

The other option is to maybe hack about one of the Audi boxes that run the output shaft between clutch and engine. Take an output shaft from the rear of the TR6060, run it down the side and into the diff.

Obviously you then have the issues of the gear linkage but that's far easier to solve!

Transmission = gearbox (manual or auto)

Differential = differential

Transaxle = some combination of the two, usually at the back of the car.

I believe a Porsche or Ferrari transaxle has the driveshafts sticking out the side of the transmission casing.

I believe the GM solution involves a transmission at the back of the car and a differential bolted straight on the back of it. In other words, the prop shaft is simply (ha-ha) moved forwards so that it's between the clutch and the transmission rather than being between the transmission and the differential.

I suspect any DIY approach would, at the very least, need some precision made adapter plates to get things to fit together. As others have already indicated an inline transmission with a differential behind it will always be quite long, which is why this approach is rarely seen in mid-engine cars. Different kettle of fish if the engine's at the front.

Differential = differential

Transaxle = some combination of the two, usually at the back of the car.

I believe a Porsche or Ferrari transaxle has the driveshafts sticking out the side of the transmission casing.

I believe the GM solution involves a transmission at the back of the car and a differential bolted straight on the back of it. In other words, the prop shaft is simply (ha-ha) moved forwards so that it's between the clutch and the transmission rather than being between the transmission and the differential.

I suspect any DIY approach would, at the very least, need some precision made adapter plates to get things to fit together. As others have already indicated an inline transmission with a differential behind it will always be quite long, which is why this approach is rarely seen in mid-engine cars. Different kettle of fish if the engine's at the front.

super_atsv said:

First post here, so hello everyone. I saw some similar posts when searching on google that brought me here and I saw plenty of 'goodluck buddy' feedback as well as helpful feedback from the community, and I am open to all criticism, concerns, considerations. The image below is a mockup photo I made of the build/style I'm going for.

A little background about me, I currently own 3 ATS-V (1 daily, 1 race car, 1 garage queen) (LF4 3.6L Twin Turbo) Since owning these 3 years ago, I've become quite familiar with the engine and general knowledge of the car doing most of all my current race car build (Road Course HPDE), but I am not a professional car builder. I have a shop with lift for my personal use where I do projects and have a wide range of tools and ability to learn. I am self taught with 3D modeling/rendering and have 3D printed my own custom ATS-V Aero parts, and am currently working on a full widebody kit for my race car.

Conveniently, next to my personal shop is a professional custom racing harness manufacturer. They are contracted by Ford directly to make custom wiring harness for high end performance ford builds like the Ford GT. They've helped me more than once with complex damaged wiring harnesses on my ATS-V with excellent work. I've brought this idea up to them and are willing to assist whenever I'm ready.

As the title says, my ideal build would be to make this a mid engine using all of the same Engine, Wiring, ECM, Transmission (TR6060 6 speed Manual) to mitigate the confusion.

This would require mating the stock TR6060 Transmission with a transaxle. From further research I've come across this Youtuber that used a corvette transaxle and wondering if anyone has done anything similar: https://www.youtube.com/watch?v=iMQGsrbxDFA

One thing I'm not sure of it how this could affect the driving/traction modes) by removing the rear diff for a C6+ transaxle

This is just one of the MANY obstacles in the build and I'm not expecting it to be easy to mount this in the rear,. There will need to be significant changes to the cabin/frame/mounting/shifter linkage and if anyone has experience with a similar project hope you'll share your wisdom with me here.

Thanks for reading

Am I missing the image or something ? I see no image.A little background about me, I currently own 3 ATS-V (1 daily, 1 race car, 1 garage queen) (LF4 3.6L Twin Turbo) Since owning these 3 years ago, I've become quite familiar with the engine and general knowledge of the car doing most of all my current race car build (Road Course HPDE), but I am not a professional car builder. I have a shop with lift for my personal use where I do projects and have a wide range of tools and ability to learn. I am self taught with 3D modeling/rendering and have 3D printed my own custom ATS-V Aero parts, and am currently working on a full widebody kit for my race car.

Conveniently, next to my personal shop is a professional custom racing harness manufacturer. They are contracted by Ford directly to make custom wiring harness for high end performance ford builds like the Ford GT. They've helped me more than once with complex damaged wiring harnesses on my ATS-V with excellent work. I've brought this idea up to them and are willing to assist whenever I'm ready.

As the title says, my ideal build would be to make this a mid engine using all of the same Engine, Wiring, ECM, Transmission (TR6060 6 speed Manual) to mitigate the confusion.

This would require mating the stock TR6060 Transmission with a transaxle. From further research I've come across this Youtuber that used a corvette transaxle and wondering if anyone has done anything similar: https://www.youtube.com/watch?v=iMQGsrbxDFA

One thing I'm not sure of it how this could affect the driving/traction modes) by removing the rear diff for a C6+ transaxle

This is just one of the MANY obstacles in the build and I'm not expecting it to be easy to mount this in the rear,. There will need to be significant changes to the cabin/frame/mounting/shifter linkage and if anyone has experience with a similar project hope you'll share your wisdom with me here.

Thanks for reading

I see no way you'd create a typical transaxle around a T56/6060 type trans. The Vette as mentioned uses a very long setup with the diff behind the gearbox. Not so much a transaxle as a regular gearbox with a diff behind it. And is what is shown in your video, just a bog standard Vette setup.

Is that what you want ? Or do you want a more conventional and much shorter transaxle ?

What are some of the complications / remedies when using a trans not designed for the motor? I’ll look into some of the other transaxles mentioned and yeah now I realize what I mentioned is actually a trans + rear diff setup not a transaxle. A transaxle seems like a more realistic way but I’m sure of how this factors into the stock ecm/tune ability /communication etc. I’ll dive into that rabbit hole now

super_atsv said:

What are some of the complications / remedies when using a trans not designed for the motor? I’ll look into some of the other transaxles mentioned and yeah now I realize what I mentioned is actually a trans + rear diff setup not a transaxle. A transaxle seems like a more realistic way but I’m sure of how this factors into the stock ecm/tune ability /communication etc. I’ll dive into that rabbit hole now

If it's a manual box it won't really care beyond maybe having a gear sensor to limit torque in lower gears. Its the autos where they really need to be holistic. Looks like my photo didn’t attach in the first post… this is just a mock-up of my ‘ultimate’ vision and it would require a lot of structural adjustments that I’m still trying to wrap my head around. what I’ve done in photoshop which is basically slicing off the entire top and sliding it forward and reshaping it. Would need to have a firewall behind the seats and build a proper mid engine bay. So the entire back no longer has a trunk but engine access hatch and suitable mounts.

The actual panels I’m fairly confident I can design, 3D print, and make composite molds. The obstacles concerned about is the ‘sliding it all forward’ and the engine framing.

The actual panels I’m fairly confident I can design, 3D print, and make composite molds. The obstacles concerned about is the ‘sliding it all forward’ and the engine framing.

SturdyHSV said:

I think the intention is to use the transaxle from a Corvette, which is a TR6060.

He'd presumably effectively just end up with an extremely short torque tube.

The Factory Five kit cars run a setup using the Vette box/diff. Even with the engine bolted directly to the box in the normal way, it makes for an incredibly long powerplantHe'd presumably effectively just end up with an extremely short torque tube.

Only suited to an equally long vehicle, but it just looks all wrong

Escy said:

How much power do you plan on having? A Porsche Boxster/Cayman LS engine swap is reasonably common in the US. You can buy all the parts required to bolt your engine up to the Porsche transaxle. I'm putting 540ft/lb through one with no issues yet.

My current ATS-V makes around 650whp /600 tq but the aftermarket turbos I have sitting could push it likely to 750whp/ tq which would be maxing out my current setup anyways under. Would be nice to have wiggle room as the platform continues to progress. The car makes plenty of power as is but you know how it is… super_atsv said:

Looks like my photo didn’t attach in the first post… this is just a mock-up of my ‘ultimate’ vision and it would require a lot of structural adjustments that I’m still trying to wrap my head around. what I’ve done in photoshop which is basically slicing off the entire top and sliding it forward and reshaping it. Would need to have a firewall behind the seats and build a proper mid engine bay. So the entire back no longer has a trunk but engine access hatch and suitable mounts.

The actual panels I’m fairly confident I can design, 3D print, and make composite molds. The obstacles concerned about is the ‘sliding it all forward’ and the engine framing.

Does it need to come from the original car in some way for class rules or something?The actual panels I’m fairly confident I can design, 3D print, and make composite molds. The obstacles concerned about is the ‘sliding it all forward’ and the engine framing.

I can't see how you'd be reducing your workload by starting with an ATS-V, I mean you can't even reuse any of the body panels at that point, you're going to end up hanging the fenders and lights off a rollcage and everything else will be bespoke

Buy a Gallardo, stick the LS in it, and make some ATS-V looking body panels. Seems infinitely cheaper and more likely to work.

SturdyHSV said:

super_atsv said:

Looks like my photo didn’t attach in the first post… this is just a mock-up of my ‘ultimate’ vision and it would require a lot of structural adjustments that I’m still trying to wrap my head around. what I’ve done in photoshop which is basically slicing off the entire top and sliding it forward and reshaping it. Would need to have a firewall behind the seats and build a proper mid engine bay. So the entire back no longer has a trunk but engine access hatch and suitable mounts.

The actual panels I’m fairly confident I can design, 3D print, and make composite molds. The obstacles concerned about is the ‘sliding it all forward’ and the engine framing.

Does it need to come from the original car in some way for class rules or something?The actual panels I’m fairly confident I can design, 3D print, and make composite molds. The obstacles concerned about is the ‘sliding it all forward’ and the engine framing.

I can't see how you'd be reducing your workload by starting with an ATS-V, I mean you can't even reuse any of the body panels at that point, you're going to end up hanging the fenders and lights off a rollcage and everything else will be bespoke

Buy a Gallardo, stick the LS in it, and make some ATS-V looking body panels. Seems infinitely cheaper and more likely to work.

http://www.lamborghiniclubwest.com/L140_LAY.jpg

Thinking about it I'd probably go with a Ricardo transaxle, that's the same that is used in the 2005-6 Ford GT and as stock that makes 550HP & 679Nm.

These are pretty trivial to bolt up to an LS http://slc-wiki.squarespace.com/ricardo

Actually tbh you'd probably be best going with something like an SLC or Ultima and sprinkle the body panels you want on top.

Edited by Fastdruid on Friday 19th August 09:20

In the real world, you'd be better off bolting the LQ4 to a Cayman transaxle and leaving the lot inside the Cayman chassis. They are a great car.

That said the Cayman gearbox probably won't take 800bhp. There's a guy in the US called Jordan, he's got a 1000+bhp LS Cayman, he was running the Audi R8/Lamborghini transaxle in that.

That said the Cayman gearbox probably won't take 800bhp. There's a guy in the US called Jordan, he's got a 1000+bhp LS Cayman, he was running the Audi R8/Lamborghini transaxle in that.

super_atsv said:

What are some of the complications / remedies when using a trans not designed for the motor? I’ll look into some of the other transaxles mentioned and yeah now I realize what I mentioned is actually a trans + rear diff setup not a transaxle. A transaxle seems like a more realistic way but I’m sure of how this factors into the stock ecm/tune ability /communication etc. I’ll dive into that rabbit hole now

You are living in an age, where almost anything, can be bolted to anything, and very possibly already has been by someone else.So what exactly do you want ?

And why force a stock ecm ? and even that will depend what stock ecm you are usign.

Yeah, my original plan was just starting with a mid engine chassis like a gollardo or a Acura nsx, or Mclaren etc. In my render i used a gollardo cabin and resituated things on the ats-v coupe. As someone mentioned it’s probably not even possible to pull of my render without totally annihilating cabin.

Starting from here looks like quite a project but probably the best/only way to even make this look proper. I’ve just got a lot of research to do about how setup suspension and everything else that’s missing so it actually drives straight and reliable.

I thought by using a ats-v chassis I could limit the amount of work but it actually maybe more trying to work around an improper base

Starting from here looks like quite a project but probably the best/only way to even make this look proper. I’ve just got a lot of research to do about how setup suspension and everything else that’s missing so it actually drives straight and reliable.

I thought by using a ats-v chassis I could limit the amount of work but it actually maybe more trying to work around an improper base

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff