Poor throttle response with Dellorto DHLA carbs

Discussion

Hiya,

I'm new here (spend most of my time on MG-related boards). Excellent site, great forums as well! Will be returning a lot I think ;-)

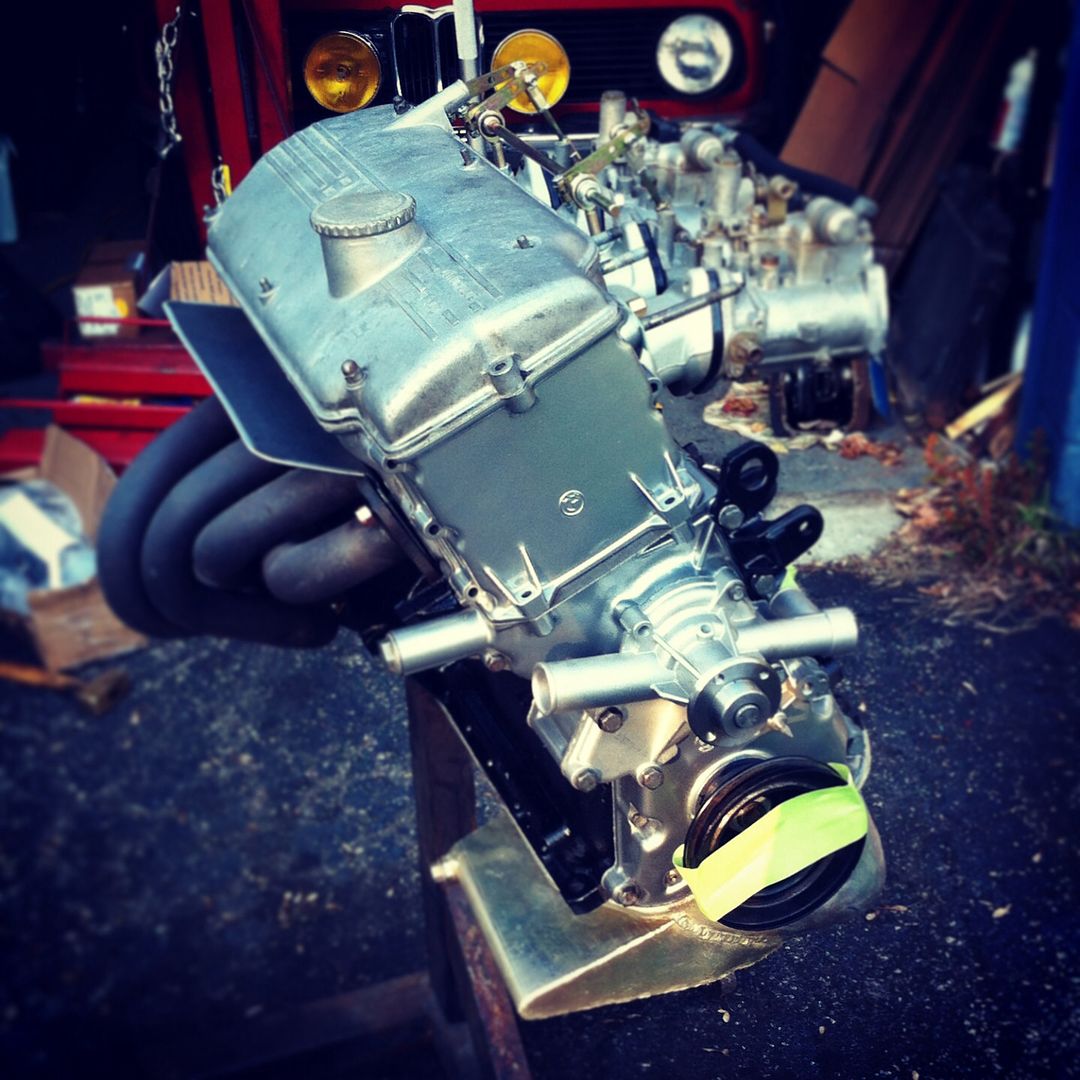

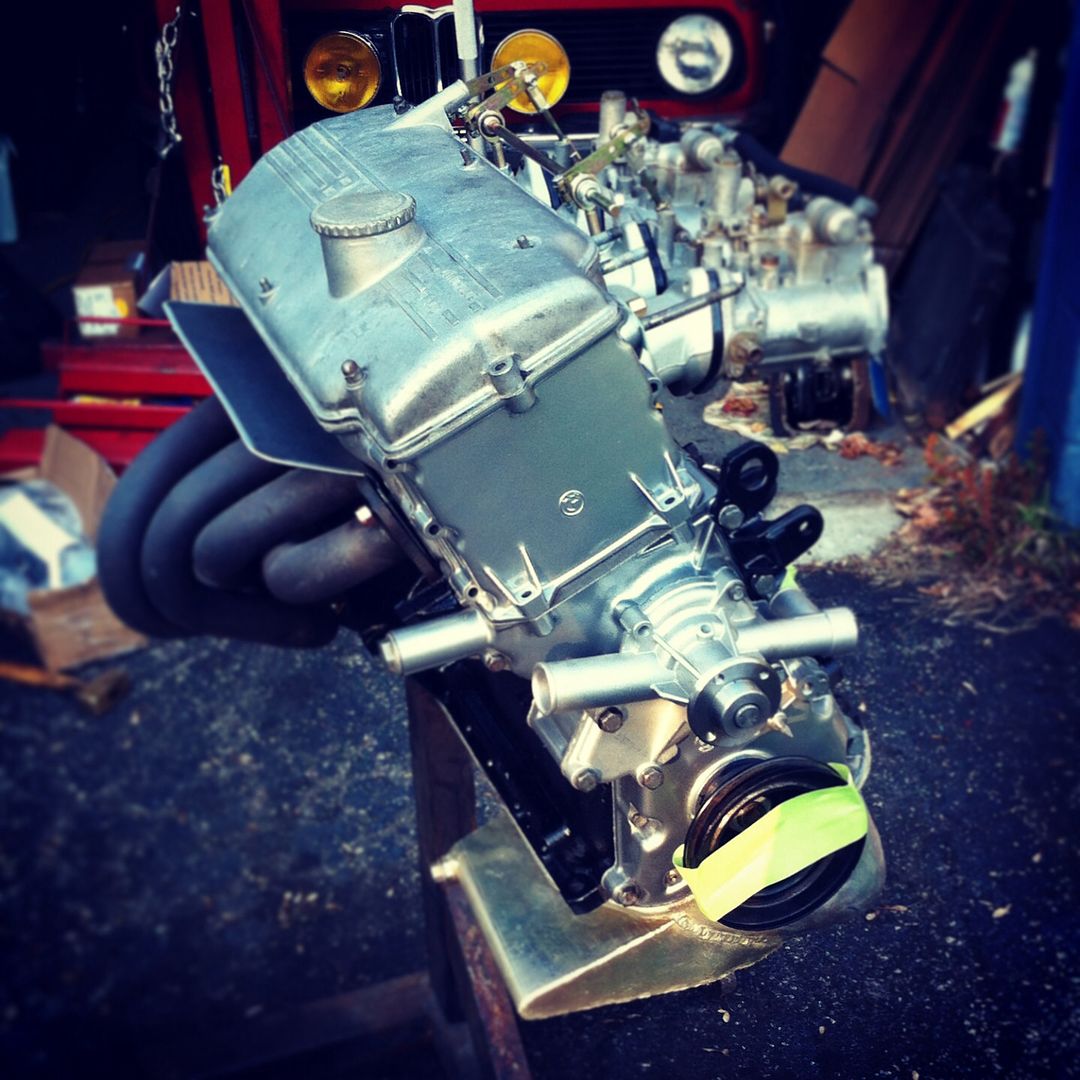

A little info about my car: MGB with B series engine, HRG Derrington crossflow head, bored to 1950cc using aluminium Accralite forged pistons, 11:1 CR, Piper 285 cam, 2 Dell'Orto 40 DHLA carbs, Aldon modified mech. advance only dizzy.

Had it setup by a tuner over here in Belgium, was done quite badly. Went to Peter Burgess this weekend, he got 150 hp out of it(124 at wheels) using other chokes (34mm instead of 30) amongst other tricks.

The car is great at full throttle but stutters rather badly at part throttle. (but that's impossible to see at the rolling road of course)

Can you please help me? I'd really like this prob to be sorted...

Cheers,

Alex in Belgium

I'm new here (spend most of my time on MG-related boards). Excellent site, great forums as well! Will be returning a lot I think ;-)

A little info about my car: MGB with B series engine, HRG Derrington crossflow head, bored to 1950cc using aluminium Accralite forged pistons, 11:1 CR, Piper 285 cam, 2 Dell'Orto 40 DHLA carbs, Aldon modified mech. advance only dizzy.

Had it setup by a tuner over here in Belgium, was done quite badly. Went to Peter Burgess this weekend, he got 150 hp out of it(124 at wheels) using other chokes (34mm instead of 30) amongst other tricks.

The car is great at full throttle but stutters rather badly at part throttle. (but that's impossible to see at the rolling road of course)

Can you please help me? I'd really like this prob to be sorted...

Cheers,

Alex in Belgium

It is a problem that occurs when your carbs are oversized. And I have a feel that could be the case, because of the increase in diameter you mentioned.

Low revs, means low flow rate in the carb, the resulting vacuum is not enough to 'pull' enough fuel. That is why very big carbs have two stages.

When your carbs have two stages, check that they work at the proper throttle opening. If the stages are not a problem (or you don't have any), it is possible to do a calculation to check if you have the correct carb dimensions.

Rob (TVR 350i, Belgium)

Low revs, means low flow rate in the carb, the resulting vacuum is not enough to 'pull' enough fuel. That is why very big carbs have two stages.

When your carbs have two stages, check that they work at the proper throttle opening. If the stages are not a problem (or you don't have any), it is possible to do a calculation to check if you have the correct carb dimensions.

Rob (TVR 350i, Belgium)

First off, I know peter burgess .. top bloke and if he says use 34mm I'd be inclined to believe him  His B series and Rover V8 heads are amongst the best you'll find anywhere, his work really is first class.

His B series and Rover V8 heads are amongst the best you'll find anywhere, his work really is first class.

Ths DHLAs tend to produce slightly smaller droplets than the equivalent choked DCOE so throttle response and fuel economy should be better than on DCOE carbs, well in theory at least.

The cam isn't very wild, so you should be ok there (little reversion in the ports at part throttle)

could do with more info really .. when you say stutters do you mean when you floor the throttle .. if so the the pump jets might be the cause .. on the DHLA you can control the time the pump jets squirt for against the rate of flow by adjusting the spring tension on the actualting lever (ie alot of fuel for a short tme or less fuel over a longer time, the same total flow in each case)

.. or does it stutter on part throttle just cruising around .. are the butterflies past teh progression drillings in the body, is the idle jetting correct (the idle jetting does the first part of part throttle fuelling too)

is there anything else you can tell us?

His B series and Rover V8 heads are amongst the best you'll find anywhere, his work really is first class.

His B series and Rover V8 heads are amongst the best you'll find anywhere, his work really is first class. Ths DHLAs tend to produce slightly smaller droplets than the equivalent choked DCOE so throttle response and fuel economy should be better than on DCOE carbs, well in theory at least.

The cam isn't very wild, so you should be ok there (little reversion in the ports at part throttle)

could do with more info really .. when you say stutters do you mean when you floor the throttle .. if so the the pump jets might be the cause .. on the DHLA you can control the time the pump jets squirt for against the rate of flow by adjusting the spring tension on the actualting lever (ie alot of fuel for a short tme or less fuel over a longer time, the same total flow in each case)

.. or does it stutter on part throttle just cruising around .. are the butterflies past teh progression drillings in the body, is the idle jetting correct (the idle jetting does the first part of part throttle fuelling too)

is there anything else you can tell us?

Thanks for the replies!

The problem is when softly accelerating (part throttle), not when suddenly depressing the gas pedal.

Idle jetting should be right, as the idle jets work al the way up to 3000 rpm, so that would be noticable when at full throttle too, right?

No probs when cruising at constant speed.

So my guess is pump jets. I'll install a set with a larger size and see what those do.

(Rob, it's nice to see there are Belgians over here!)

Thanks again,

Alex

The problem is when softly accelerating (part throttle), not when suddenly depressing the gas pedal.

Idle jetting should be right, as the idle jets work al the way up to 3000 rpm, so that would be noticable when at full throttle too, right?

No probs when cruising at constant speed.

So my guess is pump jets. I'll install a set with a larger size and see what those do.

(Rob, it's nice to see there are Belgians over here!)

Thanks again,

Alex

Alex,

It's difficult to draw any conclusions without having all the carb jetting info. Can you supply the rest of the jetting data?

34mm chokes are not out of line for a 2 litre. I'm into Lotus, not MG, but I do have several 2 liter 907 engines running DHLA 45's. Granted, it's a 4-valve twin cam verses a 2-valve push rod engine, but they're in the same range.

For a stock 2 liter 907, 35mm chokes are about right. For a lightly massaged 2.2, I use 37mm chokes on the street or 38mm on the track. 34mm chokes for your 2 liter, 2-valve crossflow, 11:1 engine sounds about right.

Not knowing anything else about your car, a stab in the dark at some generic settings would probably end up with something like this:

Carburetor ........... 40 DHLA

Chokes ............... 34mm

Main Jets ............ 140

Emulsion Tubes ....... 7772.6 or 7772.5

Air Correctors ....... 180

Idle Jets ............ 50

Idle Air Corrector ... 7850.2 (weaker, .6 or .1 / Richer .8)

Pump Jets ............ 40

Auxiliary Venturis ... 7848.2

Dellorto Idle Jet Holders (Idle Air Corrector Jets) are not numbered sequentially, but totally randomly. Don't get caught making any assumptions about which one is the next size richer or leaner based upon the number. Go by the following chart:

Weaker ................ Normal .............. Richer

7850.5, .10, .9, .4, .1, .3, .6, .7, .2, .8

Each jet is paired with an air corrector.

Main Jet / Air Corrector Jet

Idle Jet / Idle Air Corrector (Idle Jet Holder)

The jet meters the amount of fuel and the air corrector meters the amount of air that is mixed in the emulsion tubes. The idle circuit feeds the engine up to 3500 rpm (maybe 4000 rpm depending upon how everything is set up) and the main circuit feeds if from there on up. In each range (idle and main), the jet has greater impact on mixture at the low end of the range, and the air corrector has more impact on mixture at the high end. It's not correct to just plug in richer/leaner idle jets without dealing with the air correctors at the same time. The overall capacity of each circuit is limited by the jet… each size can only flow so much fuel before it max's out.

From idle, slowly open the throttle… slow enough that the accelerator pump isn't much of a factor. If the engine hesitates just off idle, then the idle mixture is too lean.

Set the idle mixture screws all out equally at about 3 to 3.5 turns and adjust the idle speed to get the idle as smooth as possible. Then slooowly open the throttle to increase the speed without help from the accelerator pump. If the engine stumbles, the mixture is too lean. Go to about a two step richer IDLE AIR CORRECTOR (jet holder, not the idle jet) and repeat.

If you get all the way to a 7850.8 air corrector (richest) and it's still too lean, then go to a larger idle jet (like from 40 to 45 or 50 to 55), back down on the air corrector to something mid-range like a 7850.1 and repeat the process working back toward a 7850.8 again. It's putzy, repetitive work, but that's how you get it right.

All that assumes the mixture is lean. If it's too rich to begin with, proceed the other way through progressively leaner combinations. Air correctors first, then the idle jets.

After the best idle jet/ air bleed combination is found, adjust the mixture screws to optimize the idle mixture for the smoothest idle. It's best to use a 4-tube manometer and adjust the screws for the strongest manifold vacuum at idle.

If the jets and bleeds were set correctly, then it shouldn't take more then +/- 1/4 turn of the screws to fine tune the mixture. Be gentle and wait 5-10 seconds between adjustments for the engine to settle down.

That's the no load idle jetting. Under load that may turn out to be too lean. If the engine stumbles under slow acceleration (no accelerator pump), especially at around 3200-3700 rpm, then picks up and keeps going, the idle circuit is running out of fuel capacity before the main circuit kicks in.

If that is so, then go richer on the idle jet until there's no stumble on slow acceleration, but leave the air bleeds alone... you're done with them now. Then adjust the mixture screws to get the smooth idle back (peak manifold vacuum at idle), and adjust the idle speed to around 1000 rpm.

The accelerator pump's affect is felt when the throttle is opened quickly. After the idle jets and air correctors are set, any stumble on rapid acceleration probably involves the accelerator pump, and should be dealt with by adjusting the pump jet and pump stroke (volume). On the Dellortos, you can also adjust the preload of the spring in the accelerator pump linkage to determine if that volume of fuel is squirted in quickly, or over a longer period of time.

Jetting the main circuit is best done with a chassis dyno and Air/Fuel Ratio meter. I'll leave that alone for now.

Good luck,

Tim Engel

Lotus Owners Oftha North

Minnesota, USA

It's difficult to draw any conclusions without having all the carb jetting info. Can you supply the rest of the jetting data?

34mm chokes are not out of line for a 2 litre. I'm into Lotus, not MG, but I do have several 2 liter 907 engines running DHLA 45's. Granted, it's a 4-valve twin cam verses a 2-valve push rod engine, but they're in the same range.

For a stock 2 liter 907, 35mm chokes are about right. For a lightly massaged 2.2, I use 37mm chokes on the street or 38mm on the track. 34mm chokes for your 2 liter, 2-valve crossflow, 11:1 engine sounds about right.

Not knowing anything else about your car, a stab in the dark at some generic settings would probably end up with something like this:

Carburetor ........... 40 DHLA

Chokes ............... 34mm

Main Jets ............ 140

Emulsion Tubes ....... 7772.6 or 7772.5

Air Correctors ....... 180

Idle Jets ............ 50

Idle Air Corrector ... 7850.2 (weaker, .6 or .1 / Richer .8)

Pump Jets ............ 40

Auxiliary Venturis ... 7848.2

Dellorto Idle Jet Holders (Idle Air Corrector Jets) are not numbered sequentially, but totally randomly. Don't get caught making any assumptions about which one is the next size richer or leaner based upon the number. Go by the following chart:

Weaker ................ Normal .............. Richer

7850.5, .10, .9, .4, .1, .3, .6, .7, .2, .8

Each jet is paired with an air corrector.

Main Jet / Air Corrector Jet

Idle Jet / Idle Air Corrector (Idle Jet Holder)

The jet meters the amount of fuel and the air corrector meters the amount of air that is mixed in the emulsion tubes. The idle circuit feeds the engine up to 3500 rpm (maybe 4000 rpm depending upon how everything is set up) and the main circuit feeds if from there on up. In each range (idle and main), the jet has greater impact on mixture at the low end of the range, and the air corrector has more impact on mixture at the high end. It's not correct to just plug in richer/leaner idle jets without dealing with the air correctors at the same time. The overall capacity of each circuit is limited by the jet… each size can only flow so much fuel before it max's out.

From idle, slowly open the throttle… slow enough that the accelerator pump isn't much of a factor. If the engine hesitates just off idle, then the idle mixture is too lean.

Set the idle mixture screws all out equally at about 3 to 3.5 turns and adjust the idle speed to get the idle as smooth as possible. Then slooowly open the throttle to increase the speed without help from the accelerator pump. If the engine stumbles, the mixture is too lean. Go to about a two step richer IDLE AIR CORRECTOR (jet holder, not the idle jet) and repeat.

If you get all the way to a 7850.8 air corrector (richest) and it's still too lean, then go to a larger idle jet (like from 40 to 45 or 50 to 55), back down on the air corrector to something mid-range like a 7850.1 and repeat the process working back toward a 7850.8 again. It's putzy, repetitive work, but that's how you get it right.

All that assumes the mixture is lean. If it's too rich to begin with, proceed the other way through progressively leaner combinations. Air correctors first, then the idle jets.

After the best idle jet/ air bleed combination is found, adjust the mixture screws to optimize the idle mixture for the smoothest idle. It's best to use a 4-tube manometer and adjust the screws for the strongest manifold vacuum at idle.

If the jets and bleeds were set correctly, then it shouldn't take more then +/- 1/4 turn of the screws to fine tune the mixture. Be gentle and wait 5-10 seconds between adjustments for the engine to settle down.

That's the no load idle jetting. Under load that may turn out to be too lean. If the engine stumbles under slow acceleration (no accelerator pump), especially at around 3200-3700 rpm, then picks up and keeps going, the idle circuit is running out of fuel capacity before the main circuit kicks in.

If that is so, then go richer on the idle jet until there's no stumble on slow acceleration, but leave the air bleeds alone... you're done with them now. Then adjust the mixture screws to get the smooth idle back (peak manifold vacuum at idle), and adjust the idle speed to around 1000 rpm.

The accelerator pump's affect is felt when the throttle is opened quickly. After the idle jets and air correctors are set, any stumble on rapid acceleration probably involves the accelerator pump, and should be dealt with by adjusting the pump jet and pump stroke (volume). On the Dellortos, you can also adjust the preload of the spring in the accelerator pump linkage to determine if that volume of fuel is squirted in quickly, or over a longer period of time.

Jetting the main circuit is best done with a chassis dyno and Air/Fuel Ratio meter. I'll leave that alone for now.

Good luck,

Tim Engel

Lotus Owners Oftha North

Minnesota, USA

Tim,

I'm with Ian here: thank you very much for the info! Excellent stuff! Your comments are being printed and I'll look into them this afternoon!

The engine was set up at a chassis dyno last week, so I presume idle and main circuit should be set up quite good (Peter Burgess is one of the most respected tuners in the MG world).

Cheers!

Alex

I'm with Ian here: thank you very much for the info! Excellent stuff! Your comments are being printed and I'll look into them this afternoon!

The engine was set up at a chassis dyno last week, so I presume idle and main circuit should be set up quite good (Peter Burgess is one of the most respected tuners in the MG world).

Cheers!

Alex

Tiny update: tried the things you suggested on the road today:

no prob when totally and utterly slowly accelerating, but as soon as I push the pedal a little deeper, the stumble appears.

I also heard from Peter and Chris that the number 50 for pump jets might be necessary, so I'll go and get a set of those and see what happens.

Thanks again for the reactions!

Alex

no prob when totally and utterly slowly accelerating, but as soon as I push the pedal a little deeper, the stumble appears.

I also heard from Peter and Chris that the number 50 for pump jets might be necessary, so I'll go and get a set of those and see what happens.

Thanks again for the reactions!

Alex

Alex M said:

Just had a look at one of the pump jets: 42 !!!!!!!!!!

Will be ordering 50's asap.

Thanks guys!

Alex

Alex M,

Just for reference...

This is the jetting I'm running in four 2.0 litre Lotus 907's and one 2.2 litre 907. There are a lot of differences between your 2-valve pushrod MG engine and the 4-valve DOHC Lotus engine, but here it is for comparison.

Carbs .............................. DHLA45E's

Tag Numbers

......Front ........................ 5295A ....... (A = Anterior)

......Rear ......................... 5294P ....... (P = Posterior)

Carb Type ....................... DHLA 45E (E= Emissions)

Choke ............................. 36 mm (35 too small, 37 okay on 2.2)

Main Jet .......................... 160

Main Air Corrector Jet ........ 230

Main Emulsion Tube ........... 7772.8

Idle Jet ........................... 50L (Lean, will try 55-58 range)

Idle Jet Holder .................. 7850.7 (Marginal? Will try .2)

Float Weight .................... 10 gr

Float Setting Height ........... 14.5 - 15.0 mm

Float Needle Valve ............. 170

Pump Jet ......................... 38V 40H (may try 38V 42H)

Starter Jet ....................... 70

Starter Emulsion Tube ........ 7482.1

Slow Running Speed ........... 900 - 1000 rpm

FYI...

Idle Air Corrector (aka, Idle Jet Holder) size progression

Weaker ............... Normal ............... Richer

7850.5, .10, .9, .4, .1, .3, .6, .7, .2, .8

Regards,

Tim Engel

Lotus Owners Oftha North

Minnesota, USA

Hey Tim, New member and in the States. Just added a nice set of DHLA40-H to my fresh built 2.0L BMW 2002.

And I'm breathing some air into this old threads lungs...

I am trying to follow your post above, and noticed that towards the end, I can't tell if you are referring to the Bleed screws for balancing throats, or the mixture screws for idle air/fuel. Can you clarify?

"...Set the idle mixture screws all out equally at about 3 to 3.5 turns and adjust the

idle speed to get the idle as smooth as possible. Then slooowly open the throttle

to increase the speed without help from the accelerator pump. If the engine

stumbles, the mixture is too lean. Go to about a two step richer IDLE AIR

CORRECTOR (jet holder, not the idle jet) and repeat.

If you get all the way to a 7850.8 air corrector (richest) and it's still too lean,

then go to a larger idle jet (like from 40 to 45 or 50 to 55), back down on the air

corrector to something mid-range like a 7850.1 and repeat the process working

back toward a 7850.8 again. It's putzy, repetitive work, but that's how you get it

right.

All that assumes the mixture is lean. If it's too rich to begin with, proceed the

other way through progressively leaner combinations. Air correctors first, then

the idle jets. (What is the symptom in the case of the initial setup being rich??)

After the best idle jet/ air bleed combination is found, adjust the mixture screws to optimize the idle mixture for the smoothest idle. It's best to use a 4-tube manometer and adjust the screws for the strongest manifold vacuum at idle.

(This is where I become confused as to which you are referring to. they seem out of order at this point, based on the previous information)

If the jets and bleeds were set correctly, then it shouldn't take more then +/- 1/4

turn of the screws to fine tune the mixture. Be gentle and wait 5-10 seconds

between adjustments for the engine to settle down....."

I am just starting tuning on these guys, and want to learn properly, from the start, the best methods for going through them.

The motor is in and running, but I can't wait to get these carbs dialed in!!! Currently it suffers from uneven vacuum per throat. So I need to drill out the bleed screw covers. Also, it pops and weezes when I slowly run up the rpm. This is where and why I need to clarify your explanation. And while driving, it doesn't like to cruise much. Stumbles real bad when cruising at one consistent speed under 3k RPM.

-Jason

And I'm breathing some air into this old threads lungs...

I am trying to follow your post above, and noticed that towards the end, I can't tell if you are referring to the Bleed screws for balancing throats, or the mixture screws for idle air/fuel. Can you clarify?

"...Set the idle mixture screws all out equally at about 3 to 3.5 turns and adjust the

idle speed to get the idle as smooth as possible. Then slooowly open the throttle

to increase the speed without help from the accelerator pump. If the engine

stumbles, the mixture is too lean. Go to about a two step richer IDLE AIR

CORRECTOR (jet holder, not the idle jet) and repeat.

If you get all the way to a 7850.8 air corrector (richest) and it's still too lean,

then go to a larger idle jet (like from 40 to 45 or 50 to 55), back down on the air

corrector to something mid-range like a 7850.1 and repeat the process working

back toward a 7850.8 again. It's putzy, repetitive work, but that's how you get it

right.

All that assumes the mixture is lean. If it's too rich to begin with, proceed the

other way through progressively leaner combinations. Air correctors first, then

the idle jets. (What is the symptom in the case of the initial setup being rich??)

After the best idle jet/ air bleed combination is found, adjust the mixture screws to optimize the idle mixture for the smoothest idle. It's best to use a 4-tube manometer and adjust the screws for the strongest manifold vacuum at idle.

(This is where I become confused as to which you are referring to. they seem out of order at this point, based on the previous information)

If the jets and bleeds were set correctly, then it shouldn't take more then +/- 1/4

turn of the screws to fine tune the mixture. Be gentle and wait 5-10 seconds

between adjustments for the engine to settle down....."

I am just starting tuning on these guys, and want to learn properly, from the start, the best methods for going through them.

The motor is in and running, but I can't wait to get these carbs dialed in!!! Currently it suffers from uneven vacuum per throat. So I need to drill out the bleed screw covers. Also, it pops and weezes when I slowly run up the rpm. This is where and why I need to clarify your explanation. And while driving, it doesn't like to cruise much. Stumbles real bad when cruising at one consistent speed under 3k RPM.

-Jason

Hi Dave

The big problem I have with Dellortos is choice of emulsion tube, I cannot find a list of richer/weaker at different rpms emulsion tube selection. With Webers it is not too bad for instance F16 weakens off midrange if too rich....cannot find same guidance with Dellortos, a customer brought in a couple of emulsion tubes as detailed on your site but they did not have the expected effect and to be honest the fuel line was not as sweet as I can achieve with Webers.

Any ideas for selection guide?

Peter

The big problem I have with Dellortos is choice of emulsion tube, I cannot find a list of richer/weaker at different rpms emulsion tube selection. With Webers it is not too bad for instance F16 weakens off midrange if too rich....cannot find same guidance with Dellortos, a customer brought in a couple of emulsion tubes as detailed on your site but they did not have the expected effect and to be honest the fuel line was not as sweet as I can achieve with Webers.

Any ideas for selection guide?

Peter

Further to my above post. I attach an image of power and fuelling on the Fiat TC 2litre we tuned.

The blue line is with 7772.6 and the red line with same jetting but 7772.5. We weakened the fuelling on the main jet and ended up with the poor yellow line for power and fuelling. In the end we had to run a little too rich on the 7772.6 which had the characteristic torque dip around 3500 rpm. The 7772.5 was also recommended by other tuners/suppliers of dellorto spares when my customer showed them the plot of power and fuelling for the 7772.6!

Peter

Hello Peter,

The post was removed because of 'self promotion' whatever that may mean, the link was to my personal (not commercial) website which has a number of (hopefully) interesting articles written over the years, one of which was specifically about the selection of jetting for DHLA carbs. I am therefore unable to supply a link for any interested parties.

I am always scrupulous when it comes to BBS postings, so it was a little galling.

A google search may turn it up however.

Dave

The post was removed because of 'self promotion' whatever that may mean, the link was to my personal (not commercial) website which has a number of (hopefully) interesting articles written over the years, one of which was specifically about the selection of jetting for DHLA carbs. I am therefore unable to supply a link for any interested parties.

I am always scrupulous when it comes to BBS postings, so it was a little galling.

A google search may turn it up however.

Dave

Does this take the prize for the oldest thread ever to be resurrected? Some interesting points though. I wonder why the OP thought that a rolling road couldn't set up part throttle operation properly. It seems the ideal place to do it to me.

Also 150 bhp from a mildly cammed road MGB, with or without a cross flow head? Hmmm! As the builder many years ago of what became one of the most successful 1950cc MGB race engines ever seen in the UK with several new circuit records in its first six months of racing, and knowing exactly how many bhp that had on an accurate engine dyno I know how vastly overinflated many rolling road numbers were for that particular car. I never did work out why it seemed to be a very specifically MGB thing that Clayton water brake rollers just couldn't get an accurate bhp figure for them. I suspect more modern rollers won't have the same issues. The customer's previous engine which he never came close to winning a race with and wouldn't pull the skin off a rice pudding was supposed to have over 150 bhp at the wheels and most of the other competitors I spoke to thought they had similar horsepower themselves - 180 bhp flywheel was oft touted.

I remember one guy coming up to us at Silverstone after practice during which Phil had taken pole by about 2 seconds a lap faster than everyone else, peering under the bonnet and asking how much power this ****ing thing has. "I've got 180 brake," he said "and you went past me on the straight like I was pulled over having a picnic lunch so god knows how many bhp your engine has."

I didn't have the heart to tell him that in that first spec with its rally cam rather than the later rebuild full race one it was actually a mere 141 flywheel bhp on Competition Engine Service's engine dyno and that his own engine was probably struggling to break 130. He wouldn't have believed me anyway if I had. He'd have just assumed it was disinformation or a wind up. It was actually more the spread of torque rather than the outright peak bhp number that made it easy to drive fast but that's for another discussion. With the full race cam and some other tweaks we pulled a good bit more out of it but never out of the 150-160 bhp bracket.

It's hard enough getting an honest 180 bhp out of a tractable rally spec Pinto with a proper eight port head, big bore, small stroke and much larger valves and higher flow than a siamese port charge robbing MGB so why so many race drivers thought they could possibly have the same out of their antiquated tractor engines is beyond me.

This was all 20 years ago mind. I wonder how many bhp people are claiming for their MGB race engines these days now that rolling roads are a bit less haphazard? The laws of physics haven't changed so I doubt anyone is screwing much more out of them than we did back then. Perhaps Peter can enlighten us.

Also 150 bhp from a mildly cammed road MGB, with or without a cross flow head? Hmmm! As the builder many years ago of what became one of the most successful 1950cc MGB race engines ever seen in the UK with several new circuit records in its first six months of racing, and knowing exactly how many bhp that had on an accurate engine dyno I know how vastly overinflated many rolling road numbers were for that particular car. I never did work out why it seemed to be a very specifically MGB thing that Clayton water brake rollers just couldn't get an accurate bhp figure for them. I suspect more modern rollers won't have the same issues. The customer's previous engine which he never came close to winning a race with and wouldn't pull the skin off a rice pudding was supposed to have over 150 bhp at the wheels and most of the other competitors I spoke to thought they had similar horsepower themselves - 180 bhp flywheel was oft touted.

I remember one guy coming up to us at Silverstone after practice during which Phil had taken pole by about 2 seconds a lap faster than everyone else, peering under the bonnet and asking how much power this ****ing thing has. "I've got 180 brake," he said "and you went past me on the straight like I was pulled over having a picnic lunch so god knows how many bhp your engine has."

I didn't have the heart to tell him that in that first spec with its rally cam rather than the later rebuild full race one it was actually a mere 141 flywheel bhp on Competition Engine Service's engine dyno and that his own engine was probably struggling to break 130. He wouldn't have believed me anyway if I had. He'd have just assumed it was disinformation or a wind up. It was actually more the spread of torque rather than the outright peak bhp number that made it easy to drive fast but that's for another discussion. With the full race cam and some other tweaks we pulled a good bit more out of it but never out of the 150-160 bhp bracket.

It's hard enough getting an honest 180 bhp out of a tractable rally spec Pinto with a proper eight port head, big bore, small stroke and much larger valves and higher flow than a siamese port charge robbing MGB so why so many race drivers thought they could possibly have the same out of their antiquated tractor engines is beyond me.

This was all 20 years ago mind. I wonder how many bhp people are claiming for their MGB race engines these days now that rolling roads are a bit less haphazard? The laws of physics haven't changed so I doubt anyone is screwing much more out of them than we did back then. Perhaps Peter can enlighten us.

Gassing Station | Engines & Drivetrain | Top of Page | What's New | My Stuff