The Alternative Italian Job - A Classic Mini Build

Discussion

Hello all,

It's time to start another build thread, I already have one thread on my BMW 325TI - "Project Mpact" which some of you may have seen, this involved taking the S54 Engine and running gear from a E46 M3 and putting it into a E46 BMW Compact, sounds simple right?..... But being rather particular how I approach things it turned out to be, well..... not so simple.

So, How to start this Thread.....I'll try not bore you all with my Mini history too much so I'll keep that short.

My first car at the age of 17 was a 998cc Mini. The car needed a bit of TLC, so in the garden with the guidance of my dad we tidied the Mini up, repaired and replaced panels to make it solid, presentable and useable. Six months later I was in a head-on collision, the Mini was written off to the point the foot peddles touched the seat and the drivers door was bent into a 'V' (the other driver lost their Licence).

No more Mini's for me..... and that's where the BMW's came into play.

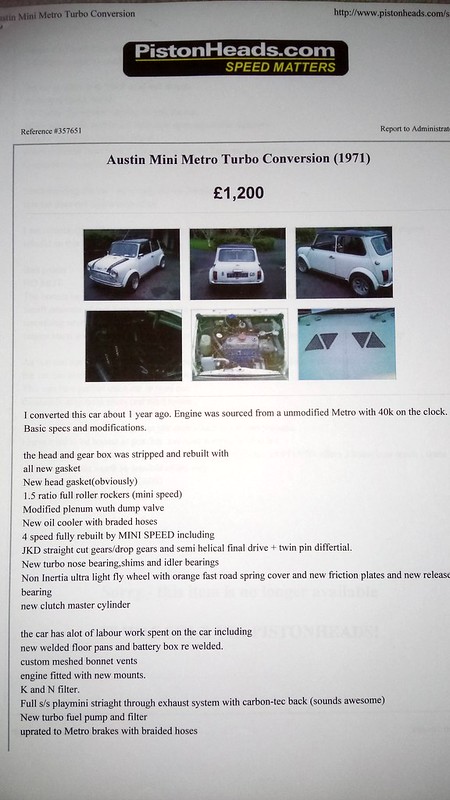

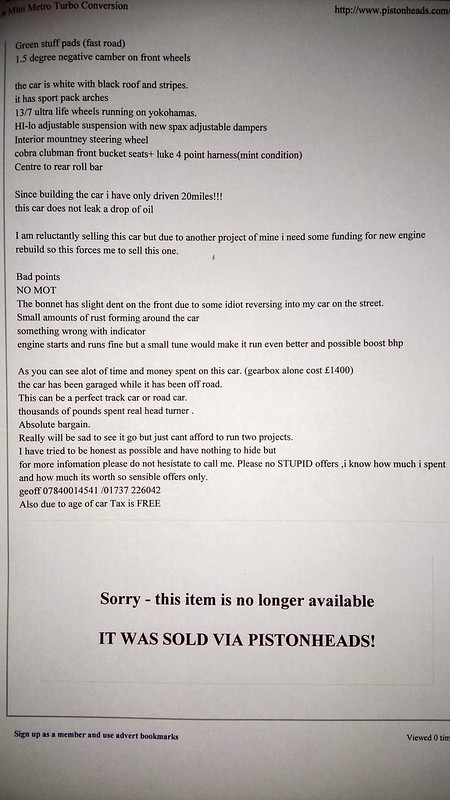

Well, that didn't last long. 3-4 years later (2008) the Mini bug bites again and the search was on, and what do I find..... A Classic mini, With a Turbo, Straight cut gearbox and list of shiney bits for sale on PistonHeads, 12 years later I'm writing about the same car on the same Website I saw it advertised.

A lot happens in 12 years, so I cant possibly go into too much detail. But I do have quite a few photo's of how the Mini has evolved over the years, as have my skills and OCD for details. It's also evolved from the the parents garden, to the driveway, to the their garage and now where it sits in my own workshop/business,

I'm going to do a bit of a rewind to where it started, how it got to be in the above "condition" and why this thread is called "The Alternative Italian Job", its not an Italian Job Mini nor is it going to be an Italian Job replica.... far from it in fact.

So, back in 2008 my Dad and I take his Volvo 360, borrow a car trailer and go to view/collect the Mini, while viewing the Mini we notice it was a bit crusty in places as with most Minis, we done the deal and bring the Mini home to the garden.

As you can see the interior was ummm, different. It had half a dashboard, there was a valve to adjust the turbo boost pressure hanging out the headunit hole and a map light.... neither of these worked. The heater was held in with wood screws, and the electrics worked when the bulldog clips holding the twisted wires were wiggled.

If you read the above advertisement, you would have noticed that New Floor Pans were "fitted", which they were, badly with the odd tack weld and what looked like bathroom silicone probably because they couldn't weld to the sills,

While my friends would be out drinking and clubbing, I was always that one person who would rather be in the garden laying under a grotty Mini, with a halogen light, angle grinder and welder in the rain or snow. Every evening, weekend and even the majority of my annual holiday was used on the Mini.

With the sills replaced, sprayed and all tidied up,

I made a new dashboard using MDF, fiberglass, filler and sprayed with an aerosol. Also fitted a steering wheel of my Dads, he'd kept it from his Mini Marcos that he owned when he was younger (when ever that was).

Onto the Engine,

It never really ran as well as I'd liked, or started when I was supposed to. It went to Avonbar to be tuned or at least set up better, and I could actually drive it after, which was nice. Shortly after I found out what torque steer felt like.... not the best with a tiny steering wheel.

I'd made a stainless exhaust, which exited out the side, just in front of the drivers side rear wheel. After a "spirited" drive it needed fuel, but I soon learned not to switch the car off after a thrashing, the turbo was directly under the carb and this caused horrendous heatsoak... I remember trying to start the Mini after filling it up (probably £25 for a full tank), and it just turning over, and over....with the entire forecourt watching eventually it started after a huge backfire and a 3 foot flame hanging out the side of the car, which took a few seconds to go out. Luckily the exhaust exited the opposite side to the petrol pump.

After that, I used to put fuel in it first thing before the car got too warm.

The Ignition was changed to Megajolt, which came as a kit.. A friend, Steve (also a Turbo Mini nut) soldered it all together, I added a trigger wheel, made a stainless bracket to hold the sensor and used Ford EDIS module (if I remember correctly). Steve plugged his laptop into it and put a base map on, and to be fair it ran the best it ever did.

An oil cooler was fitted, a friend was a mobile hydraulic maintenance chap who made and fitted the lines for me... that was the last time I saw him as he died shortly after from leukaemia.

I was given a stock 200sx intercooler, which I ended up chopping the end tanks off and remade from Aluminium, also bought a cheap intercooler bend kit from Ebay which welded like crap, No idea what kind Aluminium that was. lesson learned.

I also made a plenum so I could use a intercooler, as Metro turbo's never had one.

After being in quite a bad collision in my first Mini, I was intent on having a full roll cage.

When I was 15/16 I started my apprenticeship at a Motorsport Roll Cage Company, which went bust one week after said collision (now under new owners). So I was confident that I could fit one.

A full weld-in cage was purchased (cant remember the make), and where I was currently working (an architectural fabrication company) they let me use the workshop and equipment one weekend.

Unfortunately the cage didn't fit well and I was never happy with it.

Ignore the 1275 GT, I was meant to peel the 'G' off and just leave the 'T' for Turbo, you no.

Back in the garden putting gussets etc in the cage and doing aerosol things,

And then another dashboard was made from scratch, again. This time I converted it to a center speedo and kept it minimal. I made a wooden buck, stretched some fabric over it and fibre glassed it all,

After some filler and lots of sanding,

The car was used quite a lot for another year or so, playing with how much boost it could hold was resulting in Steve replacing the head gasket on what felt like most weekends, and a few little niggles were starting to appear.

It was at a point where I was fixing it more than driving it. My daily car had switched to the BMW Compact or "Project Mpact" as what it's now become in the last couple of years.

I had also bought a VW MK1 Caddy unfinished project, which turned out to be quite a big project in the end as the majority of it was bodged. I ended up respraying it it the garage, made the one-off wheels etc,

The Mini sat on the driveway for quite a while, it was really starting to look neglected. Although I'd put a lot of work into the car, I'd also leaned a lot from it too. Driving a stripped out Mini, with the electric fuel pump groaning, the straight cut gearbox was unbearable after 40mins driving and I was never sure if it was going to start, which didn't give much confidence to use it. It had so many patches welded over the years prior to me owning it that it had looked like a patchwork quilt. So it was time.......

It was pulled into the garage,

and cut up,

To be continued..........

It's time to start another build thread, I already have one thread on my BMW 325TI - "Project Mpact" which some of you may have seen, this involved taking the S54 Engine and running gear from a E46 M3 and putting it into a E46 BMW Compact, sounds simple right?..... But being rather particular how I approach things it turned out to be, well..... not so simple.

So, How to start this Thread.....I'll try not bore you all with my Mini history too much so I'll keep that short.

My first car at the age of 17 was a 998cc Mini. The car needed a bit of TLC, so in the garden with the guidance of my dad we tidied the Mini up, repaired and replaced panels to make it solid, presentable and useable. Six months later I was in a head-on collision, the Mini was written off to the point the foot peddles touched the seat and the drivers door was bent into a 'V' (the other driver lost their Licence).

No more Mini's for me..... and that's where the BMW's came into play.

Well, that didn't last long. 3-4 years later (2008) the Mini bug bites again and the search was on, and what do I find..... A Classic mini, With a Turbo, Straight cut gearbox and list of shiney bits for sale on PistonHeads, 12 years later I'm writing about the same car on the same Website I saw it advertised.

A lot happens in 12 years, so I cant possibly go into too much detail. But I do have quite a few photo's of how the Mini has evolved over the years, as have my skills and OCD for details. It's also evolved from the the parents garden, to the driveway, to the their garage and now where it sits in my own workshop/business,

I'm going to do a bit of a rewind to where it started, how it got to be in the above "condition" and why this thread is called "The Alternative Italian Job", its not an Italian Job Mini nor is it going to be an Italian Job replica.... far from it in fact.

So, back in 2008 my Dad and I take his Volvo 360, borrow a car trailer and go to view/collect the Mini, while viewing the Mini we notice it was a bit crusty in places as with most Minis, we done the deal and bring the Mini home to the garden.

As you can see the interior was ummm, different. It had half a dashboard, there was a valve to adjust the turbo boost pressure hanging out the headunit hole and a map light.... neither of these worked. The heater was held in with wood screws, and the electrics worked when the bulldog clips holding the twisted wires were wiggled.

If you read the above advertisement, you would have noticed that New Floor Pans were "fitted", which they were, badly with the odd tack weld and what looked like bathroom silicone probably because they couldn't weld to the sills,

While my friends would be out drinking and clubbing, I was always that one person who would rather be in the garden laying under a grotty Mini, with a halogen light, angle grinder and welder in the rain or snow. Every evening, weekend and even the majority of my annual holiday was used on the Mini.

With the sills replaced, sprayed and all tidied up,

I made a new dashboard using MDF, fiberglass, filler and sprayed with an aerosol. Also fitted a steering wheel of my Dads, he'd kept it from his Mini Marcos that he owned when he was younger (when ever that was).

Onto the Engine,

It never really ran as well as I'd liked, or started when I was supposed to. It went to Avonbar to be tuned or at least set up better, and I could actually drive it after, which was nice. Shortly after I found out what torque steer felt like.... not the best with a tiny steering wheel.

I'd made a stainless exhaust, which exited out the side, just in front of the drivers side rear wheel. After a "spirited" drive it needed fuel, but I soon learned not to switch the car off after a thrashing, the turbo was directly under the carb and this caused horrendous heatsoak... I remember trying to start the Mini after filling it up (probably £25 for a full tank), and it just turning over, and over....with the entire forecourt watching eventually it started after a huge backfire and a 3 foot flame hanging out the side of the car, which took a few seconds to go out. Luckily the exhaust exited the opposite side to the petrol pump.

After that, I used to put fuel in it first thing before the car got too warm.

The Ignition was changed to Megajolt, which came as a kit.. A friend, Steve (also a Turbo Mini nut) soldered it all together, I added a trigger wheel, made a stainless bracket to hold the sensor and used Ford EDIS module (if I remember correctly). Steve plugged his laptop into it and put a base map on, and to be fair it ran the best it ever did.

An oil cooler was fitted, a friend was a mobile hydraulic maintenance chap who made and fitted the lines for me... that was the last time I saw him as he died shortly after from leukaemia.

I was given a stock 200sx intercooler, which I ended up chopping the end tanks off and remade from Aluminium, also bought a cheap intercooler bend kit from Ebay which welded like crap, No idea what kind Aluminium that was. lesson learned.

I also made a plenum so I could use a intercooler, as Metro turbo's never had one.

After being in quite a bad collision in my first Mini, I was intent on having a full roll cage.

When I was 15/16 I started my apprenticeship at a Motorsport Roll Cage Company, which went bust one week after said collision (now under new owners). So I was confident that I could fit one.

A full weld-in cage was purchased (cant remember the make), and where I was currently working (an architectural fabrication company) they let me use the workshop and equipment one weekend.

Unfortunately the cage didn't fit well and I was never happy with it.

Ignore the 1275 GT, I was meant to peel the 'G' off and just leave the 'T' for Turbo, you no.

Back in the garden putting gussets etc in the cage and doing aerosol things,

And then another dashboard was made from scratch, again. This time I converted it to a center speedo and kept it minimal. I made a wooden buck, stretched some fabric over it and fibre glassed it all,

After some filler and lots of sanding,

The car was used quite a lot for another year or so, playing with how much boost it could hold was resulting in Steve replacing the head gasket on what felt like most weekends, and a few little niggles were starting to appear.

It was at a point where I was fixing it more than driving it. My daily car had switched to the BMW Compact or "Project Mpact" as what it's now become in the last couple of years.

I had also bought a VW MK1 Caddy unfinished project, which turned out to be quite a big project in the end as the majority of it was bodged. I ended up respraying it it the garage, made the one-off wheels etc,

The Mini sat on the driveway for quite a while, it was really starting to look neglected. Although I'd put a lot of work into the car, I'd also leaned a lot from it too. Driving a stripped out Mini, with the electric fuel pump groaning, the straight cut gearbox was unbearable after 40mins driving and I was never sure if it was going to start, which didn't give much confidence to use it. It had so many patches welded over the years prior to me owning it that it had looked like a patchwork quilt. So it was time.......

It was pulled into the garage,

and cut up,

To be continued..........

With the shell now chopped up, the front end (because it had the engine in it) and roof skin were the only bits kept.

At the same time as I'd stripped my Mini, a friend (Danny) had just stripped his Mini. I bought his shell as a donor vehicle as it seemed relatively original and straight, and from this I had datum to set new panels etc.

So with the shell already stripped I cut the inner wings off, scuttle panel and the outer sills. It was then taken to the blasted, I asked for the centres of the larger panels not to be blasted and to just concentrate on the edges and near the seams,

And this is why I'd always say "get a project blasted before any work goes ahead", there were a few surprises!

So, if you're thinking of buying a Classic Mini these are some of the main areas to look out for

I then braced the inside of the Mini with 20x20 box section, creating a frame inside the car and tack welding it into place.

After this I made a rotisserie, with some 50x50 box section and a scaffold pole. This meant cutting a hole in the back seat, but in the grand scale of things this was minor. Some mounts were made that bolted to the car, which the scaffold pole then passed through.

After a little while a shopping list was written, and then a trip to DSN Classics to collect the new replacement panels,

The majority of the panels are Heritage items, the panels appear to be made from a better quality and slightly thicker material (but doesn't mean they will fit any better) and the other panels are a good quality pattern item.

The next update I'll be chopping this shell up .

At the same time as I'd stripped my Mini, a friend (Danny) had just stripped his Mini. I bought his shell as a donor vehicle as it seemed relatively original and straight, and from this I had datum to set new panels etc.

So with the shell already stripped I cut the inner wings off, scuttle panel and the outer sills. It was then taken to the blasted, I asked for the centres of the larger panels not to be blasted and to just concentrate on the edges and near the seams,

And this is why I'd always say "get a project blasted before any work goes ahead", there were a few surprises!

So, if you're thinking of buying a Classic Mini these are some of the main areas to look out for

I then braced the inside of the Mini with 20x20 box section, creating a frame inside the car and tack welding it into place.

After this I made a rotisserie, with some 50x50 box section and a scaffold pole. This meant cutting a hole in the back seat, but in the grand scale of things this was minor. Some mounts were made that bolted to the car, which the scaffold pole then passed through.

After a little while a shopping list was written, and then a trip to DSN Classics to collect the new replacement panels,

The majority of the panels are Heritage items, the panels appear to be made from a better quality and slightly thicker material (but doesn't mean they will fit any better) and the other panels are a good quality pattern item.

The next update I'll be chopping this shell up .

I'm gonna bookmark this just for the journey...............

I actually hate minis after I spend 5 years welding up one for a nephew to see it sold when it was finished!!! The are awful things to work on and rust everywhere (I like Opels and I thought they were bad)

It's probably gonna trigger bad memories

I actually hate minis after I spend 5 years welding up one for a nephew to see it sold when it was finished!!! The are awful things to work on and rust everywhere (I like Opels and I thought they were bad)

It's probably gonna trigger bad memories

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff