Knackered old Porsche with loads of natural light - Boxster!

Discussion

poppopbangbang said:

Bright Halo said:

What material did you use for your 3d prints? Did you put captive nuts in one half or nut and bolt?

These are printed from high temp PETG which is just a brew of PETG that has a glass transition temperature above 100 degrees C. They're printed with a 0.8mm nozzle which generally gives a much stronger part due to the greater bond area between layers and depending on the part either solid or a high % on infill with a high wall thickness. This has proven to be a good setup for usable parts in several applications, the parts aren't lightweight but they are solid and extremely tough. No inserts or nuts on these, I designed them with a lot of depth in the mounting/clamping areas so they could be tapped to a decent depth and then just bolted together. PETG has the rigidity to do this on anything 1mm thread pitch and up. Torque to 5NM with a dab of blue loctite and job jobbed

I have always been nervous about using 3d print parts in the past but that was probably because I only printed with ABS.

Bright Halo said:

That is great info, thank you.

I have always been nervous about using 3d print parts in the past but that was probably because I only printed with ABS.

High Temp PETG is a bit of a game changer as it has a very similar temperature resistance to ABS, meaning you can make parts which are bolted to engine blocks etc. that don't deform in use. It's a little bit more expensive but the increased impact resiliance and general strength more than makes up for that. It's well worth buying a roll of normal PETG and having a play with it before moving to the high temp stuff as you can get the settings dialed in pretty well on that without the additional cost. I have always been nervous about using 3d print parts in the past but that was probably because I only printed with ABS.

As always desiging for 3D print comes in too as you'll need to take into account that these aren't machined parts so some areas will have to be thicker to get the required strength, on the charge cooler header tank mount above you can see where clamping/mounting surfaces are overly thick to provide sufficient thread engagement/strength.

Next month is an option for Dyno but I am not sure I can make the date as I've somehow accidently gone back to work full time for a few weeks  It's for a good program though!

It's for a good program though!

I've applied for the Booster to be in the Readers Cars section of the upcoming PH Annual Service at Bicester, if picked I'll post here so if anyone is coming along and wants a chat / look around it then it would be my pleasure

It's for a good program though!

It's for a good program though! I've applied for the Booster to be in the Readers Cars section of the upcoming PH Annual Service at Bicester, if picked I'll post here so if anyone is coming along and wants a chat / look around it then it would be my pleasure

Well those Hanon coolers are pretty amazing!

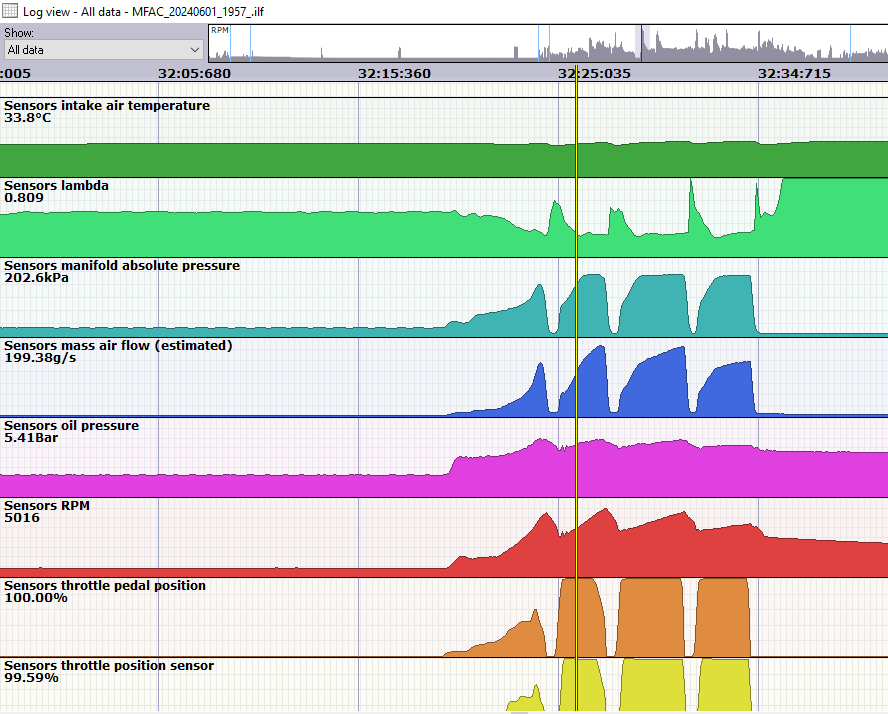

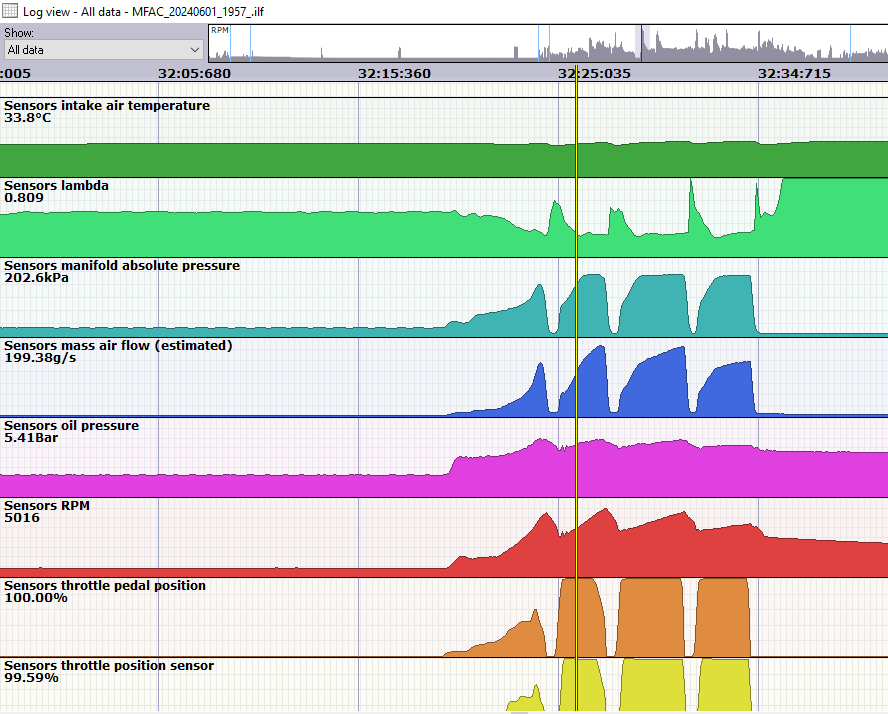

1.4bar boost, 18 degrees ambient, 36 degrees C inlet temp during a pull. It doesn't get any higher than that until the coolant becomes saturated. No wonder the Mclaren tuners in the states around doing 350 beans+ a side on these with them still in a loop off the engine coolant!

The coolant becomes saturated fairly quickly at the moment as the Mocal oil cooler I've nailed into the rad duct as a temporary measure is not exactly suitable for this application, I've got that problem in hand though.... or rather PWR have:

This is in production now so should be on the car by the end of the month. It's a 26mm low temp core so should be very efficient at getting the heat out the charge cooler loop. Development is going pretty well really as I've about boxed off a solution for a standard engine making up to 300bhp with a hybrid on it and one for 400bhp+ with a whopping great turbo on it. The P13 chargecoolers seems to be fairly available either from cars which have been upgraded or GT4 cars that have had a moment as the brackets snap off in a minor shunt (which is great as you don't need those for Boxster/Booster use )

)

I'm going to aim for the next dyno session in mid July with a target of 400bhp which was the original none WI target on this turbo. That means I've got an exhaust system to sort out next. I still want to meet drive by noise / static noise test for all UK circuits so it'll be a big cat and a big silencer relative to the amount of exhaust energy left to silence.

In other related updates I've been dailying it on dry days as it's wild in the wet for one wheel peels , there's a new set of Michelins to go on it and the roof works a treat with the new engine cover.

, there's a new set of Michelins to go on it and the roof works a treat with the new engine cover.

1.4bar boost, 18 degrees ambient, 36 degrees C inlet temp during a pull. It doesn't get any higher than that until the coolant becomes saturated. No wonder the Mclaren tuners in the states around doing 350 beans+ a side on these with them still in a loop off the engine coolant!

The coolant becomes saturated fairly quickly at the moment as the Mocal oil cooler I've nailed into the rad duct as a temporary measure is not exactly suitable for this application, I've got that problem in hand though.... or rather PWR have:

This is in production now so should be on the car by the end of the month. It's a 26mm low temp core so should be very efficient at getting the heat out the charge cooler loop. Development is going pretty well really as I've about boxed off a solution for a standard engine making up to 300bhp with a hybrid on it and one for 400bhp+ with a whopping great turbo on it. The P13 chargecoolers seems to be fairly available either from cars which have been upgraded or GT4 cars that have had a moment as the brackets snap off in a minor shunt (which is great as you don't need those for Boxster/Booster use

)

)I'm going to aim for the next dyno session in mid July with a target of 400bhp which was the original none WI target on this turbo. That means I've got an exhaust system to sort out next. I still want to meet drive by noise / static noise test for all UK circuits so it'll be a big cat and a big silencer relative to the amount of exhaust energy left to silence.

In other related updates I've been dailying it on dry days as it's wild in the wet for one wheel peels

, there's a new set of Michelins to go on it and the roof works a treat with the new engine cover.

, there's a new set of Michelins to go on it and the roof works a treat with the new engine cover.eltax91 said:

Nope just the screen washer nozzle for the headlight. Stuck my inflator down the filler neck and blew it out…. Onward.

How does that happen? Something gets jammed on when using the windscreen washers?If you're at a track day shouldn't the screenwash be at minimum anyway for weight saving?

braddo said:

eltax91 said:

Nope just the screen washer nozzle for the headlight. Stuck my inflator down the filler neck and blew it out…. Onward.

How does that happen? Something gets jammed on when using the windscreen washers?If you're at a track day shouldn't the screenwash be at minimum anyway for weight saving?

eltax91 said:

:Shrug: from the limited reading I’ve done today the nozzle tip cracks and just starts leaking. Wonder if the spirited ‘using all the kerb’ just before the mountain upset it?

The nozzles act as a restriction that the pump overcomes, if something upstream of the pump but downstream of the nozzle breaks then the fluid moving in the reservoir pumps it out the break. Completely normal phenomenon

Hope you've had a great day on circit

poppopbangbang said:

eltax91 said:

:Shrug: from the limited reading I’ve done today the nozzle tip cracks and just starts leaking. Wonder if the spirited ‘using all the kerb’ just before the mountain upset it?

The nozzles act as a restriction that the pump overcomes, if something upstream of the pump but downstream of the nozzle breaks then the fluid moving in the reservoir pumps it out the break. Completely normal phenomenon

Hope you've had a great day on circit

poppopbangbang said:

eltax91 said:

:Shrug: from the limited reading I’ve done today the nozzle tip cracks and just starts leaking. Wonder if the spirited ‘using all the kerb’ just before the mountain upset it?

The nozzles act as a restriction that the pump overcomes, if something upstream of the pump but downstream of the nozzle breaks then the fluid moving in the reservoir pumps it out the break. Completely normal phenomenon

Hope you've had a great day on circit

king panicking if I had seen that at a track day and I would never have thought it might just be screenwash

king panicking if I had seen that at a track day and I would never have thought it might just be screenwash

ETA - reminds me of the first time a stone got caught in a brake disc/caliper. I was terrified - young guy, have taken my Elise into France for the first time, girlfriend was shouting, thought the car was broken. Mechanic friend suggested reversing a bit and seeing how it goes...

Edited by braddo on Thursday 6th June 21:35

braddo said:

Good to know, and I'm hoping it's rare, because I would be f king panicking if I had seen that at a track day and I would never have thought it might just be screenwash

king panicking if I had seen that at a track day and I would never have thought it might just be screenwash

ETA - reminds me of the first time a stone got caught in a brake disc/caliper. I was terrified - young guy, have taken my Elise into France for the first time, girlfriend was shouting, thought the car was broken. Mechanic friend suggested reversing a bit and seeing how it goes...

There was, of course, an initial flurry of panic. But the liquid was obviously blue and upon closer inspection smelled very much like screen wash.  king panicking if I had seen that at a track day and I would never have thought it might just be screenwash

king panicking if I had seen that at a track day and I would never have thought it might just be screenwash

ETA - reminds me of the first time a stone got caught in a brake disc/caliper. I was terrified - young guy, have taken my Elise into France for the first time, girlfriend was shouting, thought the car was broken. Mechanic friend suggested reversing a bit and seeing how it goes...

Edited by braddo on Thursday 6th June 21:35

Didn’t take very long to witness it slowly leaking out of the nozzle tips

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff