Knackered old Porsche with loads of natural light - Boxster!

Discussion

Next month is an option for Dyno but I am not sure I can make the date as I've somehow accidently gone back to work full time for a few weeks  It's for a good program though!

It's for a good program though!

I've applied for the Booster to be in the Readers Cars section of the upcoming PH Annual Service at Bicester, if picked I'll post here so if anyone is coming along and wants a chat / look around it then it would be my pleasure

It's for a good program though!

It's for a good program though! I've applied for the Booster to be in the Readers Cars section of the upcoming PH Annual Service at Bicester, if picked I'll post here so if anyone is coming along and wants a chat / look around it then it would be my pleasure

Well those Hanon coolers are pretty amazing!

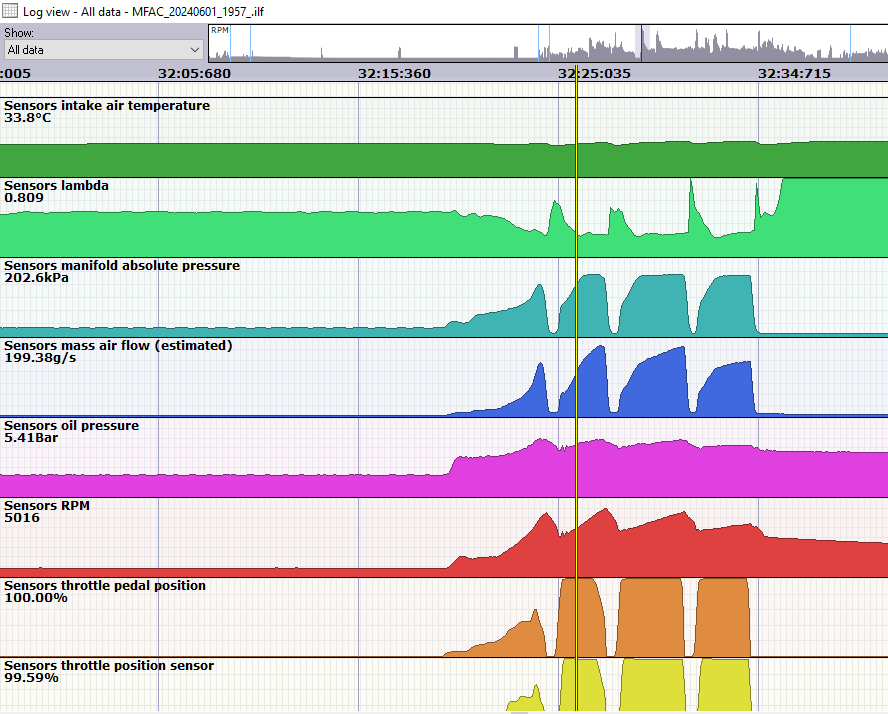

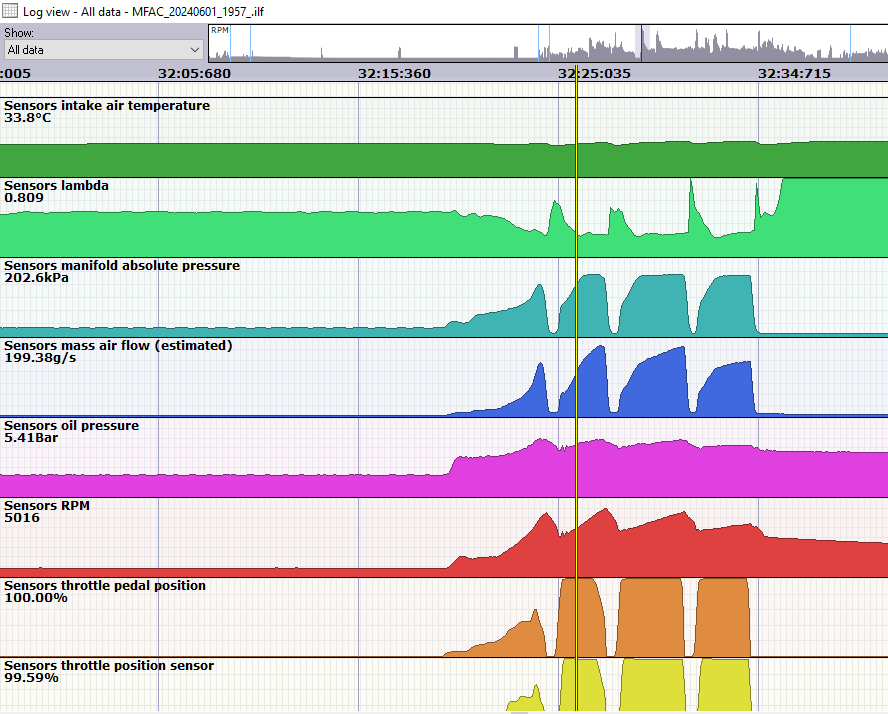

1.4bar boost, 18 degrees ambient, 36 degrees C inlet temp during a pull. It doesn't get any higher than that until the coolant becomes saturated. No wonder the Mclaren tuners in the states around doing 350 beans+ a side on these with them still in a loop off the engine coolant!

The coolant becomes saturated fairly quickly at the moment as the Mocal oil cooler I've nailed into the rad duct as a temporary measure is not exactly suitable for this application, I've got that problem in hand though.... or rather PWR have:

This is in production now so should be on the car by the end of the month. It's a 26mm low temp core so should be very efficient at getting the heat out the charge cooler loop. Development is going pretty well really as I've about boxed off a solution for a standard engine making up to 300bhp with a hybrid on it and one for 400bhp+ with a whopping great turbo on it. The P13 chargecoolers seems to be fairly available either from cars which have been upgraded or GT4 cars that have had a moment as the brackets snap off in a minor shunt (which is great as you don't need those for Boxster/Booster use )

)

I'm going to aim for the next dyno session in mid July with a target of 400bhp which was the original none WI target on this turbo. That means I've got an exhaust system to sort out next. I still want to meet drive by noise / static noise test for all UK circuits so it'll be a big cat and a big silencer relative to the amount of exhaust energy left to silence.

In other related updates I've been dailying it on dry days as it's wild in the wet for one wheel peels , there's a new set of Michelins to go on it and the roof works a treat with the new engine cover.

, there's a new set of Michelins to go on it and the roof works a treat with the new engine cover.

1.4bar boost, 18 degrees ambient, 36 degrees C inlet temp during a pull. It doesn't get any higher than that until the coolant becomes saturated. No wonder the Mclaren tuners in the states around doing 350 beans+ a side on these with them still in a loop off the engine coolant!

The coolant becomes saturated fairly quickly at the moment as the Mocal oil cooler I've nailed into the rad duct as a temporary measure is not exactly suitable for this application, I've got that problem in hand though.... or rather PWR have:

This is in production now so should be on the car by the end of the month. It's a 26mm low temp core so should be very efficient at getting the heat out the charge cooler loop. Development is going pretty well really as I've about boxed off a solution for a standard engine making up to 300bhp with a hybrid on it and one for 400bhp+ with a whopping great turbo on it. The P13 chargecoolers seems to be fairly available either from cars which have been upgraded or GT4 cars that have had a moment as the brackets snap off in a minor shunt (which is great as you don't need those for Boxster/Booster use

)

)I'm going to aim for the next dyno session in mid July with a target of 400bhp which was the original none WI target on this turbo. That means I've got an exhaust system to sort out next. I still want to meet drive by noise / static noise test for all UK circuits so it'll be a big cat and a big silencer relative to the amount of exhaust energy left to silence.

In other related updates I've been dailying it on dry days as it's wild in the wet for one wheel peels

, there's a new set of Michelins to go on it and the roof works a treat with the new engine cover.

, there's a new set of Michelins to go on it and the roof works a treat with the new engine cover.eltax91 said:

:Shrug: from the limited reading I’ve done today the nozzle tip cracks and just starts leaking. Wonder if the spirited ‘using all the kerb’ just before the mountain upset it?

The nozzles act as a restriction that the pump overcomes, if something upstream of the pump but downstream of the nozzle breaks then the fluid moving in the reservoir pumps it out the break. Completely normal phenomenon

Hope you've had a great day on circit

In the interests of continuous improvement I've managed to source a 4 Pin D shape male connector which is pin compatible with that moulded into the standard Coolant Temp Sensor. In short that means with a bit of 3D printing, soldering, potting and crimping we get a Coolant Temp Sensor which is plug and play with the standard 20V wiring harness but avoids the clash with the top of the engine bay when said 20V is in a Boxster

You can see the height difference here:

And plug compatible:

Pleased with that

You can see the height difference here:

And plug compatible:

Pleased with that

Mikeeb said:

Does that mean less cutting of the engine cover?

No, it just means the engine fits with sufficient space around everything to allow for movement. You can get it in with the standard setup but it is on the loom from the CTS doing so.This is the standard setup:

This elbow ends up under the metal work at the back of the engine bay. The clearance above the black connector to said metal work is too close.

This was my original bodge:

Which was fairly bulky and involved shrinking a boot down on it, I also couldn't get the mating half for the loom side connector so involved repinning the loom to a 4 way flat connector.

But the new one is properly potted to strain relieve the solder joints on the top of the CTS, is more compact so has even more clearance and has a mating half connector that plugs straight into a standard loom.

Basically it's all much nicer, it doesn't work any better or really change anything.... but it's nicer and sometimes nicer is all that matters

This is probably going to be a bit on the loud side, although the turbo does take a lot of energy out of the exhaust:

Big low loss CAT into a small 250mm silencer and then straight out the back!

I've designed it as a straight swap for the rear silencer that is on there at the moment so it's an easy swap back if it's too loud and obnoxious It'll definitely solve the current back pressure issue though!

It'll definitely solve the current back pressure issue though!

Big low loss CAT into a small 250mm silencer and then straight out the back!

I've designed it as a straight swap for the rear silencer that is on there at the moment so it's an easy swap back if it's too loud and obnoxious

It'll definitely solve the current back pressure issue though!

It'll definitely solve the current back pressure issue though! Well all the exhaust bits / bends are on the way and should be here Thursday, I've got to decide what I'm doing with regards mounting it to the car next. I'm definitely going to retain the back of gearbox mount but picking up on that in a sensible way may require a bit of thinking as supporting an amount of adjustment is going to be the order of the day! I'm also a little concerned that the growth with temperature is going to make the tailpipe walk in the recess but we'll see how that works out....

PWR are on track with the chargecooler rad so that should be here in the next week or so, whilst I've got the bumper off to fit the the Chargecooler rad I'm going to get that painted as it's really letting the car down, it's been badly rattle can'd at least twice

As all the bits are within sight I've booked some more time on the dyno mid July. Really looking forward to running it again with the obvious bits resolved and seeing what it'll make

Finally it's off to CG post dyno for suspension so with that on there it's about done....... well nearly, I've got a few reliability mods planned including an electric water pump to keep the coolant circulating through the rads/engine/turbo when the engine is shut down and some further electronics integration between dash and ECU (and maybe a few extra sensors) so I can run downshift blip etc.

The big thing I'm pondering might be a bit polarising though.....

Cayman conversion - I expect it will be an utter arse as it's one piece GRP so almost certainly won't be the same side to side and it's designed to retain the soft top in a stowed position so will likely need some modification to support a Cayman style parcel shelf but I do really like the idea of a 986 Cayman! What do we reckon?

PWR are on track with the chargecooler rad so that should be here in the next week or so, whilst I've got the bumper off to fit the the Chargecooler rad I'm going to get that painted as it's really letting the car down, it's been badly rattle can'd at least twice

As all the bits are within sight I've booked some more time on the dyno mid July. Really looking forward to running it again with the obvious bits resolved and seeing what it'll make

Finally it's off to CG post dyno for suspension so with that on there it's about done....... well nearly, I've got a few reliability mods planned including an electric water pump to keep the coolant circulating through the rads/engine/turbo when the engine is shut down and some further electronics integration between dash and ECU (and maybe a few extra sensors) so I can run downshift blip etc.

The big thing I'm pondering might be a bit polarising though.....

Cayman conversion - I expect it will be an utter arse as it's one piece GRP so almost certainly won't be the same side to side and it's designed to retain the soft top in a stowed position so will likely need some modification to support a Cayman style parcel shelf but I do really like the idea of a 986 Cayman! What do we reckon?

mattdavies said:

Really enjoy this thread.

On the above I am pretty sure that the seat Ibiza Cupra that first came with this enigne had this feature, I remeber a friends car making noise post shut down, therefore i am guessing an OEM style integration might be possible ( I dont know much about OEM ECU Electrickery )

Yes very possible, that implementation was mainly to stop water boiling in the turbo whereas I am looking at a more significant pump that will still create some circulation but the principle is exactly the same!On the above I am pretty sure that the seat Ibiza Cupra that first came with this enigne had this feature, I remeber a friends car making noise post shut down, therefore i am guessing an OEM style integration might be possible ( I dont know much about OEM ECU Electrickery )

ECU wise the Ignitron unit I use has a "stay awake" function based on coolant temp, battery voltage, elapsed time etc. so entirely possible to implement this ECU driven so it only runs when both the engine and bay temp are high (although one rather follows the other!).

The package works well and I've clocked up a decent amount of mileage so addressing the reliability boosters is a good option at this point as nothing significant will be changing in the integration etc. it'll just be getting used harder and harder

I think I may have done a terrible job of explaining what I meant by Cayman kit in my earlier post. Both the cars in my post are 986 Boxsters, not Caymans but they're fitted with a replacement hard top and boot lid section that essentially creates a 986 Cayman in terms of bodyshape:

These are made in GRP so likely to be an utter arse to make fit nicely as I have no idea of the tooling quality etc.

There's a couple of reasons for considering this, one is the obvious aero benefits, I'd like to do some top speed / VMAX stuff in the car eventually, if only to get there first before anyone else who's building one, but I am not massively confident in the current 25 year old well used soft top to at 180mph. It would also significantly improve some aspects of the engine access as I could make a simple (even window'd!) engine cover that could be easily accessed through the tail gate.... it also gives the option of feeding an airbox through the rear quarter glass.

I do like the OE hardtop and did consider that as an option but there a few reasons against it, not least as Escy pointed out it's got to come off everytime to access the engine.

With regards doing an actual Cayman kit, the current kit mostly bolts into a 987 so mechnaically there already is one - the electronics integration is far more significant however and the liability of reverse engineering comms with things like ABS which can have a distinct impact on the operation of the brakling and stability systems in a worst case situation is more than I'm willing to take on for the sort of volumes we're talking here. The 986 ABS system on the 2.5L pre 2000 cars is essentially stand alone and will run without MIL or drama just as it did with the original engine as long as all the vehicle speeds etc. are present and correct. The 986 kit doesn't require any modifications to the chassis loom so all this stays as it left Porsche so it's very easy to make a functional safety case or it vs the 987.

These are made in GRP so likely to be an utter arse to make fit nicely as I have no idea of the tooling quality etc.

There's a couple of reasons for considering this, one is the obvious aero benefits, I'd like to do some top speed / VMAX stuff in the car eventually, if only to get there first before anyone else who's building one, but I am not massively confident in the current 25 year old well used soft top to at 180mph. It would also significantly improve some aspects of the engine access as I could make a simple (even window'd!) engine cover that could be easily accessed through the tail gate.... it also gives the option of feeding an airbox through the rear quarter glass.

I do like the OE hardtop and did consider that as an option but there a few reasons against it, not least as Escy pointed out it's got to come off everytime to access the engine.

With regards doing an actual Cayman kit, the current kit mostly bolts into a 987 so mechnaically there already is one - the electronics integration is far more significant however and the liability of reverse engineering comms with things like ABS which can have a distinct impact on the operation of the brakling and stability systems in a worst case situation is more than I'm willing to take on for the sort of volumes we're talking here. The 986 ABS system on the 2.5L pre 2000 cars is essentially stand alone and will run without MIL or drama just as it did with the original engine as long as all the vehicle speeds etc. are present and correct. The 986 kit doesn't require any modifications to the chassis loom so all this stays as it left Porsche so it's very easy to make a functional safety case or it vs the 987.

jeremyc said:

ow about trying something a little different for the Cayman: a normally aspriated, high revving screamer installation?

It won't have the absolute power of the turbocharged version, but might be a more engaging drive and also perhaps a lower cost and more easily packaged option.

I am a big fan of high rev'ing NA engines, primarily due to my motorsport past, but the bottom line is a decent 11K RPM+ motor (which is actually high rev'ing, anything below 11K is just playing at it) is more than a Cayman. I'd love to do a VJ at circa 16K or maybe a 4 litre JUDD at 11K but then you're into some sort of significant gearbox too..... £120K drivetrain in a £20K Cayman may be a little bit OTT It won't have the absolute power of the turbocharged version, but might be a more engaging drive and also perhaps a lower cost and more easily packaged option.

ATM said:

Is this still in production as I thought the business died long ago. Or are you going to make your own ... from scratch?

Still made in the Far East, mostly for a US company I believe but I've used the same factory previously for some production car stuff so entirely order'able if required.... I am still undecided though, although there are some amazing name suggestions that have been made so far!

PWR doing great work as always! :

Very much looking forward to getting this on the car, I'm still deciding whether to bite 2 kg more and smoke a bigger header tank in there whilst it's apart... there is a lot of additional thermal mass in 2 kg of coolant!

With this and the new exhaust on it'll be ready for the dyno again, I'm quite excited to see how much poke it has this time around.

Very much looking forward to getting this on the car, I'm still deciding whether to bite 2 kg more and smoke a bigger header tank in there whilst it's apart... there is a lot of additional thermal mass in 2 kg of coolant!

With this and the new exhaust on it'll be ready for the dyno again, I'm quite excited to see how much poke it has this time around.

ricola said:

'Home built by Jeff' on youtube fitted one of those roof kits on his audi V8 converted boxster track car. Looks an arse of a job to do it nicely!

I've seen the car but had missed the video of him fitting it, found it earlier and it's about as bad as I thought it would be

Thanks for giving me the heads up on it

Charge cooler rad is fitted:

It positively walked on there so fair play to PWR for holding the tolerances specificed on the original drawing so well!

With the rad duct on it'll be hard to tell its not an air-con rad once it's weathered in a little. Definitley no room to do anything bigger than this in the duct in terms of core thickness

I'm going to a 2.5L header tank (which I should have finished over the next couple of days) and I'll implement a strategy to run the low speed fans when the vehicle speed is below 10 kph which should also help with heat soak from the coolant rad.

All in all I'm very happy how the charge cooling has come together on this, high boost mid engined cars are an arse to make work nicely (especially without chopping things about or doing an RS200 roof mounted IC) and the setup now should see it sub 40 degrees charge temp in nearly all use cases.

Once I've polished this off it's time to crack on with the exhaust

It positively walked on there so fair play to PWR for holding the tolerances specificed on the original drawing so well!

With the rad duct on it'll be hard to tell its not an air-con rad once it's weathered in a little. Definitley no room to do anything bigger than this in the duct in terms of core thickness

I'm going to a 2.5L header tank (which I should have finished over the next couple of days) and I'll implement a strategy to run the low speed fans when the vehicle speed is below 10 kph which should also help with heat soak from the coolant rad.

All in all I'm very happy how the charge cooling has come together on this, high boost mid engined cars are an arse to make work nicely (especially without chopping things about or doing an RS200 roof mounted IC) and the setup now should see it sub 40 degrees charge temp in nearly all use cases.

Once I've polished this off it's time to crack on with the exhaust

ATM said:

Not sure if mentioned already but the guy who built the CLR lightweight cut some holes in the arch liners behind the rads to help airflow. The later cars have this out the box-ster or booster. I can get some pics from my 981 if you like. Let me know.

I think the rear rad ducts are also quite different on the 997 etc. to support this as the standard fan shroud on the 986 and 996 are enclosed and duct into the floor infront of the arch. I'll have a look on the parts diagrams to see - good suggestion! Don't really have to worry about wheel arch positive pressure on road cars

Tanks done!

2.5L capacity so around 2L more coolant in the system than previously.

Just a cheapy off the shelf generic tank modified to fit with some 19mm skin fittings and a 3D printed cap.... the later because I don't have any bar stock the correct size to spin one up on the lathe and it's not going to arrive until Friday. I'll swap it out in due course.

It's mounted via a 3D printed bracket off the bottom inner surface of the crash bar which puts it in about the only position it will fit in due to the extra length and width of the tank.

Bit of evidence on the crash bar of a few different options explored but it's all basically lightweighting so all good Fill is via the under frunk expansion tank that sits up in the corner of the frunk, so if it is ever neccesary to drain the system down from the rear of the car then it can be refilled without removing the front bumper etc.

Fill is via the under frunk expansion tank that sits up in the corner of the frunk, so if it is ever neccesary to drain the system down from the rear of the car then it can be refilled without removing the front bumper etc.

On the subject of front bumper that's gone to paint which should freshen the front end up a little, it has been very badly painted in the past so it should rather sort things out. The rest of the car is pretty decent with the usual patina for 25 years of use so it'll be nice see it fairly presentable

Time for a bit of welding next to fab the new exhaust....

2.5L capacity so around 2L more coolant in the system than previously.

Just a cheapy off the shelf generic tank modified to fit with some 19mm skin fittings and a 3D printed cap.... the later because I don't have any bar stock the correct size to spin one up on the lathe and it's not going to arrive until Friday. I'll swap it out in due course.

It's mounted via a 3D printed bracket off the bottom inner surface of the crash bar which puts it in about the only position it will fit in due to the extra length and width of the tank.

Bit of evidence on the crash bar of a few different options explored but it's all basically lightweighting so all good

Fill is via the under frunk expansion tank that sits up in the corner of the frunk, so if it is ever neccesary to drain the system down from the rear of the car then it can be refilled without removing the front bumper etc.

Fill is via the under frunk expansion tank that sits up in the corner of the frunk, so if it is ever neccesary to drain the system down from the rear of the car then it can be refilled without removing the front bumper etc. On the subject of front bumper that's gone to paint which should freshen the front end up a little, it has been very badly painted in the past so it should rather sort things out. The rest of the car is pretty decent with the usual patina for 25 years of use so it'll be nice see it fairly presentable

Time for a bit of welding next to fab the new exhaust....

Well this lot looks good, I just need to turn it into an exhaust now! The chaps at Jetex managed to find me an exhaust tailpipe that is extremely similar to the original Boxster one so it should all be pretty stealthy looks wise..... noise wise it may be a little different

The tight 180 required may impact gas flow a bit but it's about the only way to package this given the space available and it'll be a considerable improvement on the standard 2.5L back box regardless.

Aiming to fire the welder up this weekend

Gassing Station | Readers' Cars | Top of Page | What's New | My Stuff