Vixen dashboard query

Discussion

I'm replacing the dash and see the gauge area is either routed out or it's two laminated ply sheets with the rear one cut away in that area. Is it the thing to use two sheets or rout out this area, or just use say 12mm ply and cut the gauge legs back a bit for the increased thickness? Anyone out there done this?

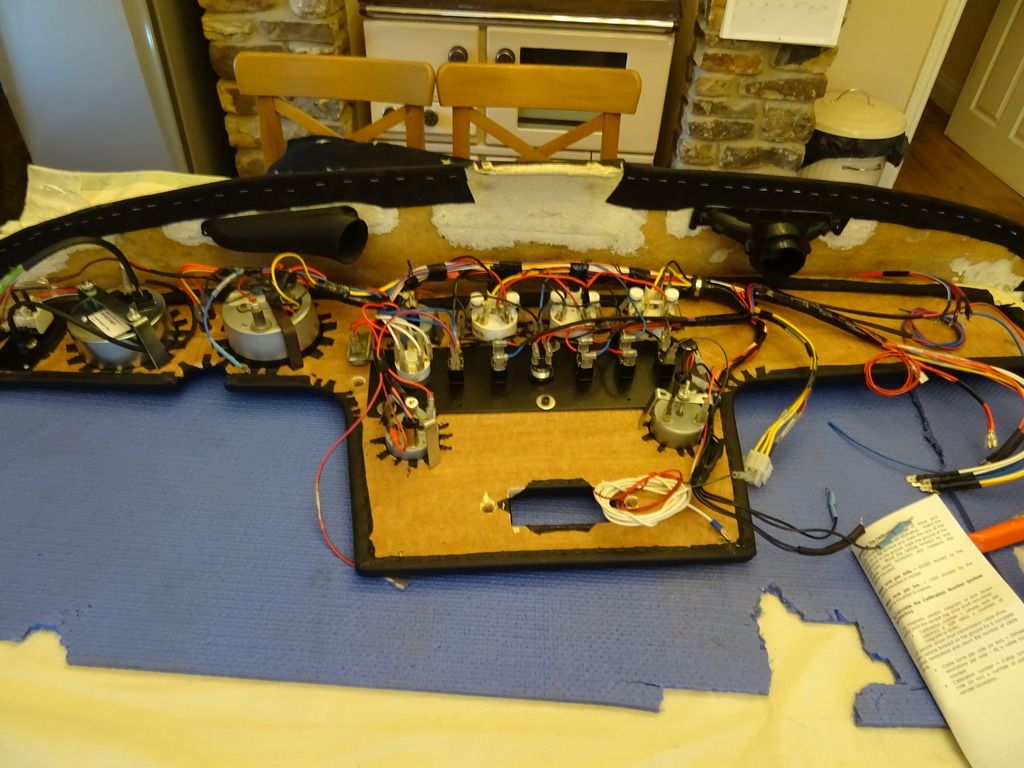

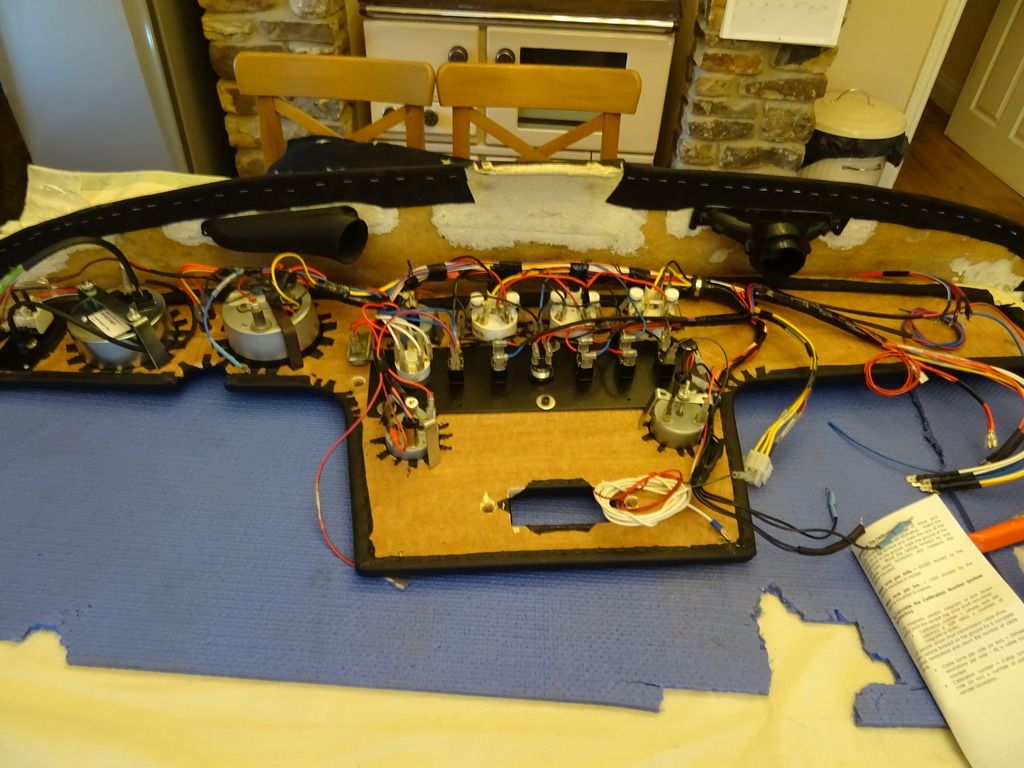

Here's the rear view with recessed area I'm talking about:

Here's the rear view with recessed area I'm talking about:

Keep the dash as thick as possible. in my experience they start to delaminate where they have been routed out. Pretty sure the routing was to facilitate the heater valves rather than the Gauges.

Its better though not original to cut out and utilise a ally insert panel.

View of recessed detail

N.

Its better though not original to cut out and utilise a ally insert panel.

View of recessed detail

N.

Edited by Dollyman1850 on Friday 14th October 20:47

Edited by Dollyman1850 on Friday 14th October 20:51

Dollyman1850 said:

Keep the dash as thick as possible. in my experience they start to delaminate where they have been routed out. Pretty sure the routing was to facilitate the heater valves rather than the Gauges.

Its better though not original to cut out and utilise a ally insert panel.

N.

Ali panel is a good idea I'll think on that. The old dash looks like two sheets but that may just be delanination. Its better though not original to cut out and utilise a ally insert panel.

N.

Is your column high or dash in that area low? My column just misses the dash so I don't think a cutout is needed there. Yes the routing may just be important for heater controls I'll do a mockup for gauges but think they'll work without and if push comes to shove the fixing legs can be ground down to suit.

When i am making a new dash for the S3 i will sandwich two pieces mainly to allow at the glove box side to re enforce that area with a thin alloy sheet between the two pieces at that end as that end is very weak on the Tuscan if it was not for the extra screws used when i fitted the glove box it would be very weak.

Andrew Gray said:

When i am making a new dash for the S3 i will sandwich two pieces mainly to allow at the glove box side to re enforce that area with a thin alloy sheet between the two pieces at that end as that end is very weak on the Tuscan if it was not for the extra screws used when i fitted the glove box it would be very weak.

You're better off backing it up with sheet as if you sandwich how do you run it out? The original was 9mm and the crash pad overlap will easily take 12mm plus a 4mm ish front layer to avoid routing. Routing isn't good. Back up the dial areas with glued Ali or stell and that also aid earthing. It's a complicated dash that's for sure - must have given TVR some headaches and the heater knob was a doomed detail

Edited by V6Pushfit on Sunday 16th October 22:04

Yes, countersunk set screws, used with a half nut on inside, made secure with loctite before dash is covered. I do same to attach the glove box, passenger side of dash then becomes very rigid.

Bracket bolted between speedo & tacho secured same way. Triumph herald column clamp can be then used. Much better than bit of steel, 2 woodscrew & a jubilee clip.

Bracket bolted between speedo & tacho secured same way. Triumph herald column clamp can be then used. Much better than bit of steel, 2 woodscrew & a jubilee clip.

Gassing Station | TVR Classics | Top of Page | What's New | My Stuff