Big power Westfield build

Discussion

Evening all,

I have a general engine build thread running in the technical section but wanted to run an idea ref radiator mounting past the combined knowledge of peeps here.

The engine is a turbo YB with a power target of 450-500bhp with the emphasis on response and reliability. With that in mind I have removed chargecooler and engine rad I was using last year and am going to air to air intercooler mounted at the front. It`s an 18x12x4.5" so quite thick and with end tanks will fill nosecone.

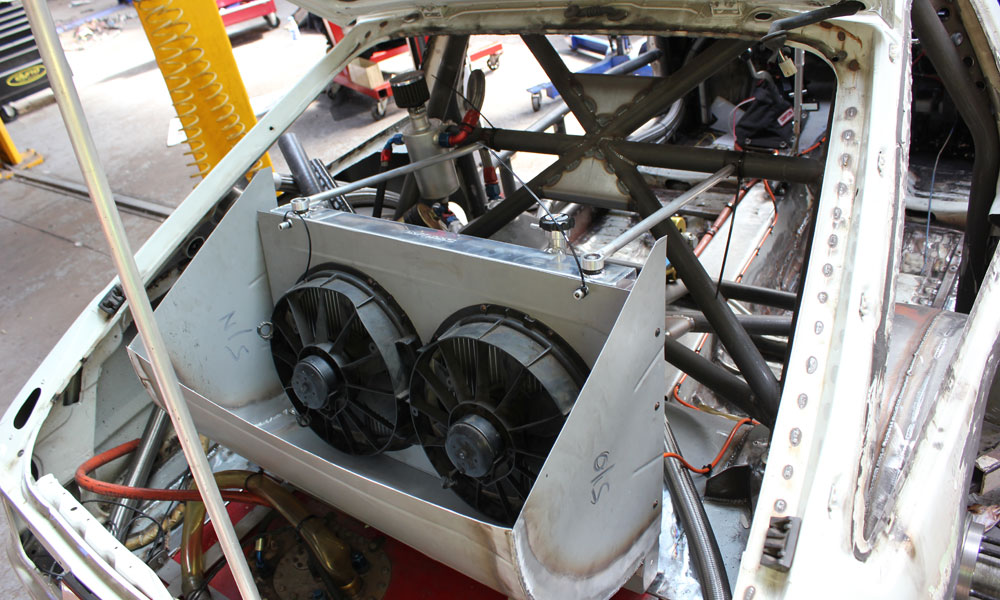

I want to remove the engine radiator to the rear of the car just behind the roll cage in the airflow. This way I can fit a full size 50mm thick cosworth radiator instead of the major compromise of a nosecone radiator. Somehow doubling the power of the engine (and more) and seriously reducing the frontal area of the rad no matter what you did re ducting etc, never rang true to me.

The rad in the roll over part of the cage at the rear will see clean airflow and not be subject to the low pressure you can get at the very rear of the car.

Has anyone done this before? Any advice? Questions are will I need a supplemental water pump? Any clues on plumbing?

Am I mad?

I have a general engine build thread running in the technical section but wanted to run an idea ref radiator mounting past the combined knowledge of peeps here.

The engine is a turbo YB with a power target of 450-500bhp with the emphasis on response and reliability. With that in mind I have removed chargecooler and engine rad I was using last year and am going to air to air intercooler mounted at the front. It`s an 18x12x4.5" so quite thick and with end tanks will fill nosecone.

I want to remove the engine radiator to the rear of the car just behind the roll cage in the airflow. This way I can fit a full size 50mm thick cosworth radiator instead of the major compromise of a nosecone radiator. Somehow doubling the power of the engine (and more) and seriously reducing the frontal area of the rad no matter what you did re ducting etc, never rang true to me.

The rad in the roll over part of the cage at the rear will see clean airflow and not be subject to the low pressure you can get at the very rear of the car.

Has anyone done this before? Any advice? Questions are will I need a supplemental water pump? Any clues on plumbing?

Am I mad?

That is exactly what I mean but obviously in a Westy there is no bodywork there.

The rad will fit perfectly in the rear roll bar.

I`ve actually just bought a full roll cage but the idea is the same. I will probably sit the rad 4-5 inches away from supports behind rear of the seats and duct it in a way that if it did spring a leak it wouldn't leak on me!

The rad will fit perfectly in the rear roll bar.

I`ve actually just bought a full roll cage but the idea is the same. I will probably sit the rad 4-5 inches away from supports behind rear of the seats and duct it in a way that if it did spring a leak it wouldn't leak on me!

Don't forget that the water pipes will take a fair bit of space, and that they will radiate a lot of heat, even in an open Westie, it will toast you on most days if the plumbing is internal. If you run them external, then they will be vulnerable unless they're tucked up rather near the propshaft.

Been following this since you bought it, would be great to see it back on the road!

I'm with elliot, having the rad horizontal with ducting seems the best idea. I know space is limited under the boot cover, so why not put it higher than the current boot cover and box it in?

Vertically against the back of the roll bar seems like it would act as a huge windbreak - Would that be enough alter the handling balance at high speed?

The option to consider - have you got any room for a twin rad set up, one each side?

Might be worth asking on WSCC too, those guys usually come up with some good ideas.

I'm with elliot, having the rad horizontal with ducting seems the best idea. I know space is limited under the boot cover, so why not put it higher than the current boot cover and box it in?

Vertically against the back of the roll bar seems like it would act as a huge windbreak - Would that be enough alter the handling balance at high speed?

The option to consider - have you got any room for a twin rad set up, one each side?

Might be worth asking on WSCC too, those guys usually come up with some good ideas.

Why not mount it on the rear lid with the front edge raised say 5-6 inch? The rad then becomes the duct. You would still need some decent fans on the hot side but it would be venting upwards, away from the fuel and, totally unrestricted. There should be enough air getting in there and you could even box it in a bit if you liked.

You could even play around with the angle to reduce / increase cooling.

You could even play around with the angle to reduce / increase cooling.

Alternatively you could look at twin rads mounted behind the rear wheels. You could then have side scoops feeding the air over the rear archs to the rads. Should give you plenty of air and would be exiting into a nice low pressure area helping pull the air through.

Only issue would be reducing the cr@p the front wheels kick up into the scoops. Maybe some decent mesh would be enough?

Only issue would be reducing the cr@p the front wheels kick up into the scoops. Maybe some decent mesh would be enough?

chuntington101 said:

Alternatively you could look at twin rads mounted behind the rear wheels. You could then have side scoops feeding the air over the rear archs to the rads. Should give you plenty of air and would be exiting into a nice low pressure area helping pull the air through.

Only issue would be reducing the cr@p the front wheels kick up into the scoops. Maybe some decent mesh would be enough?

Front mudguards make a huge difference. Only issue would be reducing the cr@p the front wheels kick up into the scoops. Maybe some decent mesh would be enough?

I`ve had some contact with the owner of that DAX. He was experiencing some overheating "issues" on track.

I`m going to buy an el cheapo ebay cossie rad to do some experimenting.

I`ve been doing quite a lot of research and it seems the ram-air effect is very important in radiators and they also don`t like being sloped........unless you have the rad constructed that way, i.e water tubes at 45 degrees like this: http://www.ahfabrications.com/information.php?info...

I don`t want to compromise air flow and just have two massive fans constantly running.

With regard to aerodynamic drag, I may sit the bottom of the rad just below boot line and duct air out the rear to keep frontal surface area more optimal. Westie`s have such poor aerodynamic performance anyway that if I get great cooling on track and on the road and the trade off is drag...........the car is meant to be a 40-130ish monster.

twin Side pods overcomplicates things for me, Pete at Spec R suggested the same but had to concede this would work and was fairly simple.

I`m going to buy an el cheapo ebay cossie rad to do some experimenting.

I`ve been doing quite a lot of research and it seems the ram-air effect is very important in radiators and they also don`t like being sloped........unless you have the rad constructed that way, i.e water tubes at 45 degrees like this: http://www.ahfabrications.com/information.php?info...

I don`t want to compromise air flow and just have two massive fans constantly running.

With regard to aerodynamic drag, I may sit the bottom of the rad just below boot line and duct air out the rear to keep frontal surface area more optimal. Westie`s have such poor aerodynamic performance anyway that if I get great cooling on track and on the road and the trade off is drag...........the car is meant to be a 40-130ish monster.

twin Side pods overcomplicates things for me, Pete at Spec R suggested the same but had to concede this would work and was fairly simple.

Paul Drawmer said:

Don't forget that the water pipes will take a fair bit of space, and that they will radiate a lot of heat, even in an open Westie, it will toast you on most days if the plumbing is internal. If you run them external, then they will be vulnerable unless they're tucked up rather near the propshaft.

Will be running them through the tunnel with heat shielding.Mr MXT said:

Been following this since you bought it, would be great to see it back on the road!

I'm with elliot, having the rad horizontal with ducting seems the best idea. I know space is limited under the boot cover, so why not put it higher than the current boot cover and box it in?

Vertically against the back of the roll bar seems like it would act as a huge windbreak - Would that be enough alter the handling balance at high speed?

The option to consider - have you got any room for a twin rad set up, one each side?

Might be worth asking on WSCC too, those guys usually come up with some good ideas.

It`s been off the road a while now! I have managed about 3000 miles since I bought it, not a lot! It was going very well until the last incident. The new engine is being built to a 650bhp plus spec and turned down for reliability.I'm with elliot, having the rad horizontal with ducting seems the best idea. I know space is limited under the boot cover, so why not put it higher than the current boot cover and box it in?

Vertically against the back of the roll bar seems like it would act as a huge windbreak - Would that be enough alter the handling balance at high speed?

The option to consider - have you got any room for a twin rad set up, one each side?

Might be worth asking on WSCC too, those guys usually come up with some good ideas.

I`ve been trying to re-sign up for WSCC membership but can`t seem to get hold of anyone.

chuntington101 said:

There are loads of rads out there that are angled. Even production cars like the GM C7 (although not a good example as they over heat). I don't even think F1 cars use that style of angled rad!

I can assure you they do! in F1 they will tilt a radiator to the rear and to the side and then manufacture the water channels to suit.jontysafe said:

chuntington101 said:

There are loads of rads out there that are angled. Even production cars like the GM C7 (although not a good example as they over heat). I don't even think F1 cars use that style of angled rad!

I can assure you they do! in F1 they will tilt a radiator to the rear and to the side and then manufacture the water channels to suit.jontysafe said:

Will have a bit of a play around!

Is it wrong that I like the look of those slanted core radiators from an engineering point of view? I rang them today but no answer.

No they do look cool and I can see how they work. They do not require the air to change direction which is always helpful. However in many applications, esp front mounted radiators, you need the air to change direction in order to leave the car properly. So in the sitations a normal core is just as efficient as you need to turn the air anyway. Is it wrong that I like the look of those slanted core radiators from an engineering point of view? I rang them today but no answer.

Gassing Station | Kit Cars | Top of Page | What's New | My Stuff