Tractive Dampers & OEM mounting bolt

Discussion

Morning all. I've had my A110 ( non-S / base) since March and loved the OEM suspension. Yes it rolled a little too much for my liking on the corners but it breathed with the road, similar to the MX5 I had before.

A trip to the Maritime Alps (Col du Turini etc.) back in May highlighted the lack of the dampers to manage high frequency inputs when 'driving with enthusiasm', so after looking at the various options placed an order for Tractive dampers (digressive front, linear rear) via Race Shocks.

Mid summer I noticed a heavy clunking noise from the rear OEM suspension when using a road that I avoid Oct-May due to the water run off from adjacent fields, allied with the terrible surface, akin to cobbles. I put it down to the surface but then noticed it on other sharp suspension inputs.

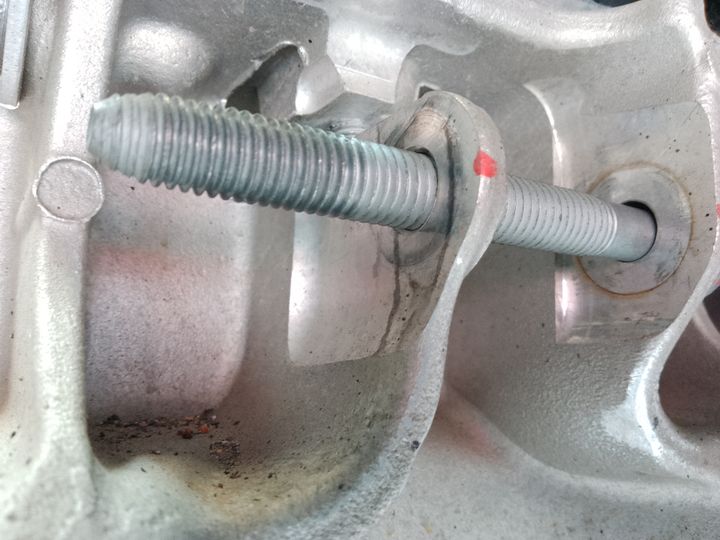

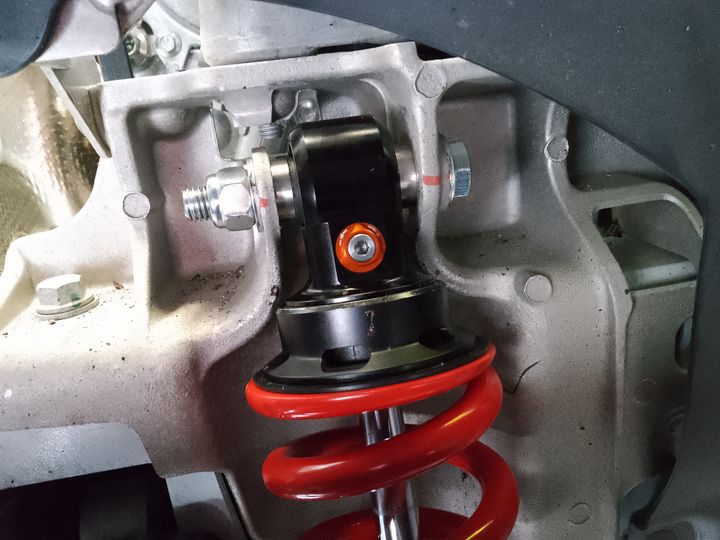

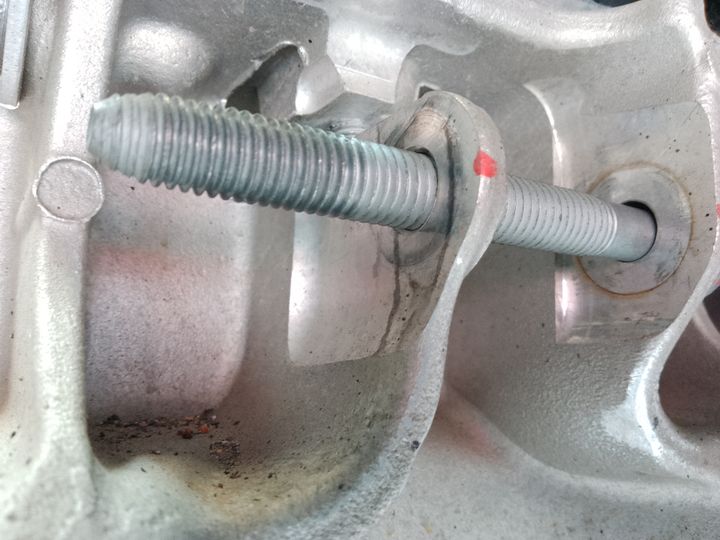

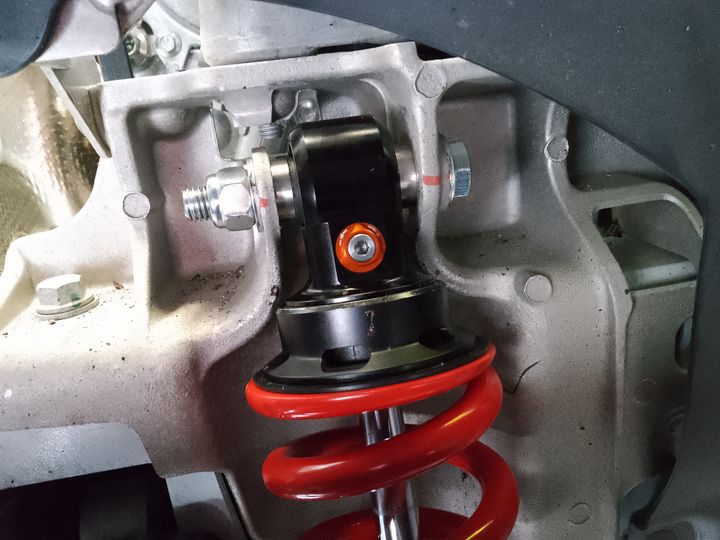

Had the Tractive dampers installed this week by Simon and the team and they found a 1mm difference between the thread and shank on the (needlessly long ! ) mounting bolt. Pics of the gap and then the replacement (short ! ) bolt in position.

Happily this has cured 90 % of the 'clunk' which was definitely a nasty metal on metal sound, but it's still there on the sharpest of inputs. Any one got any ideas where it's coming from, little short of dismantling and examining the wishbone setup ?

A trip to the Maritime Alps (Col du Turini etc.) back in May highlighted the lack of the dampers to manage high frequency inputs when 'driving with enthusiasm', so after looking at the various options placed an order for Tractive dampers (digressive front, linear rear) via Race Shocks.

Mid summer I noticed a heavy clunking noise from the rear OEM suspension when using a road that I avoid Oct-May due to the water run off from adjacent fields, allied with the terrible surface, akin to cobbles. I put it down to the surface but then noticed it on other sharp suspension inputs.

Had the Tractive dampers installed this week by Simon and the team and they found a 1mm difference between the thread and shank on the (needlessly long ! ) mounting bolt. Pics of the gap and then the replacement (short ! ) bolt in position.

Happily this has cured 90 % of the 'clunk' which was definitely a nasty metal on metal sound, but it's still there on the sharpest of inputs. Any one got any ideas where it's coming from, little short of dismantling and examining the wishbone setup ?

Are you sure the non-threaded shank diameter is indeed 1mm smaller than the thread diameter? Have you measured it?

As it's a common metric M12x1.75 flanged head bolt, the shank diameter must be exactly the same as the thread diameter, 12.0 mm, unless it has been stretched, what is unlikely as it is a 10.9 grade.

As it's a common metric M12x1.75 flanged head bolt, the shank diameter must be exactly the same as the thread diameter, 12.0 mm, unless it has been stretched, what is unlikely as it is a 10.9 grade.

That’s interesting, and a little worrying, but not uncommon. Back in my Honda days, and recently with our race Mini R53, we had issues of a similar kind, where the subframe and chassis holes were much bigger than the bolts used to affix the two. Spoon Sports knew this and developed and have for some time sold Rigid Collar kits that treat these issues. See here for info: https://youtu.be/zWyUD6UXfog?feature=shared

I don’t yet know if there is something available to solve the issue you’ve shown on the A110 but I’ll ask Spoon what they recommend.

James

I don’t yet know if there is something available to solve the issue you’ve shown on the A110 but I’ll ask Spoon what they recommend.

James

AL Peen said:

Morning all. I've had my A110 ( non-S / base) since March and loved the OEM suspension. Yes it rolled a little too much for my liking on the corners but it breathed with the road, similar to the MX5 I had before.

A trip to the Maritime Alps (Col du Turini etc.) back in May highlighted the lack of the dampers to manage high frequency inputs when 'driving with enthusiasm', so after looking at the various options placed an order for Tractive dampers (digressive front, linear rear) via Race Shocks.

Mid summer I noticed a heavy clunking noise from the rear OEM suspension when using a road that I avoid Oct-May due to the water run off from adjacent fields, allied with the terrible surface, akin to cobbles. I put it down to the surface but then noticed it on other sharp suspension inputs.

Had the Tractive dampers installed this week by Simon and the team and they found a 1mm difference between the thread and shank on the (needlessly long ! ) mounting bolt. Pics of the gap and then the replacement (short ! ) bolt in position.

Happily this has cured 90 % of the 'clunk' which was definitely a nasty metal on metal sound, but it's still there on the sharpest of inputs. Any one got any ideas where it's coming from, little short of dismantling and examining the wishbone setup ?

Hi - when you sat Tractive, I assume you mean the semi active set up with adjustable valving etc, if so fascinated to hear your thoughts on how this works with the A110 ?A trip to the Maritime Alps (Col du Turini etc.) back in May highlighted the lack of the dampers to manage high frequency inputs when 'driving with enthusiasm', so after looking at the various options placed an order for Tractive dampers (digressive front, linear rear) via Race Shocks.

Mid summer I noticed a heavy clunking noise from the rear OEM suspension when using a road that I avoid Oct-May due to the water run off from adjacent fields, allied with the terrible surface, akin to cobbles. I put it down to the surface but then noticed it on other sharp suspension inputs.

Had the Tractive dampers installed this week by Simon and the team and they found a 1mm difference between the thread and shank on the (needlessly long ! ) mounting bolt. Pics of the gap and then the replacement (short ! ) bolt in position.

Happily this has cured 90 % of the 'clunk' which was definitely a nasty metal on metal sound, but it's still there on the sharpest of inputs. Any one got any ideas where it's coming from, little short of dismantling and examining the wishbone setup ?

Not the 'electronic' semi-active. I had the one way adjustable coilovers, such as the AST / Nitron / KW offerings.

I wouldn't touch those. Talk about a sledgehammer to crack a nut. How could you drive with any confidence with a set up that is constantly re-valving from second to second, let alone crest to corner to dip to corner to crest to dip.....

Basic confidence in any car comes from linearity of response from the steering, brakes, throttle and suspension.

I don't know what the AST spring rates are, probably similar to the Life progressive springs (43 N/mm front, 80 rear) but the Nitron and KWs are way too high. We went 40 / 80 with the Tractive, set to 6 soft, 12 soft.

Simon piloted the test drive (literally, being a Caterham racer) down the local archetypal B-road and it didn't lack any control or finesse. It was borderline at the speed I'd be prepared to drive on a public road, but I got the impression he was probably driving at about 50 % of his powers.

Insert funny video :-

https://www.youtube.com/watch?v=qKmuZ87rGzI

I wouldn't touch those. Talk about a sledgehammer to crack a nut. How could you drive with any confidence with a set up that is constantly re-valving from second to second, let alone crest to corner to dip to corner to crest to dip.....

Basic confidence in any car comes from linearity of response from the steering, brakes, throttle and suspension.

I don't know what the AST spring rates are, probably similar to the Life progressive springs (43 N/mm front, 80 rear) but the Nitron and KWs are way too high. We went 40 / 80 with the Tractive, set to 6 soft, 12 soft.

Simon piloted the test drive (literally, being a Caterham racer) down the local archetypal B-road and it didn't lack any control or finesse. It was borderline at the speed I'd be prepared to drive on a public road, but I got the impression he was probably driving at about 50 % of his powers.

Insert funny video :-

https://www.youtube.com/watch?v=qKmuZ87rGzI

Gassing Station | Alpine | Top of Page | What's New | My Stuff