Epic HWA Evo edges closer

Just to see an Evo is to want one - wait until you hear what's coming under the skin

Remember when HWA CEO Martin Marx said back in the summer not to call the Evo a restomod? Simply too much of it was new, he reckoned, for that catch-all term to be applied. However useful it is. Now with new engineering details released by HWA, we know to just what extent that statement is accurate.

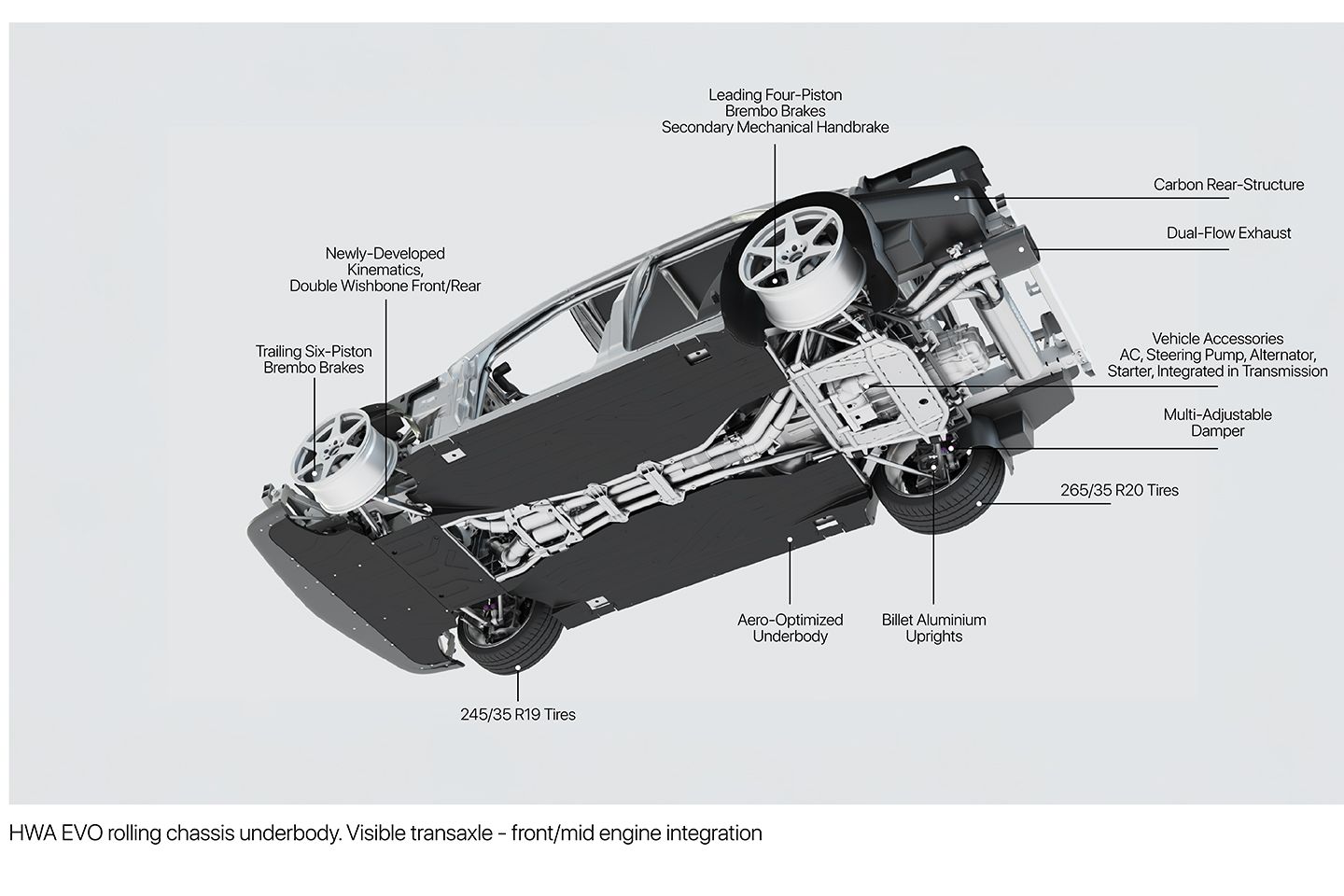

HWA suggests that 75 per cent of an Evo is new, so you can see why they’re keen for it not to be seen as merely an updated version of an old car. And even those bits that are kept are extensively overhauled. The steel midsection is retained from a W201 190, including the A-, B- and C-pillars, albeit seriously beefed up: torsional stiffness is said to be more than 100 per cent improved. Both front and rear subframes are new, allowing the KW suspension - adjustable either manually or electronically, depending on spec - to be mounted directly to the chassis, ‘creating a rigid platform for maximum handling precision and feedback.’

Speaking of that structure, it’s worth pointing out the new bodywork as well. In addition to its purpose of creating the wildest looking 190 yet seen, the carbon panels actually serve as a structural element. Amazingly, both front and rear ends are single carbon fibre structures (so really, really don’t damage them); HWA says that making them ‘is highly challenging’ - you don’t say - though adds that the process ‘contributes to the finished car’s exceptional rigidity while enabling its remarkably light kerbweight.’ You can see why they’re less than keen on ‘restomod’.

Seemingly no element has been left untouched in the quest to create the ultimate reincarnation of an iconic supersaloon. The front subframe allows the twin-turbo V6 to be sited a decent way back in the chassis, so it’s technically front mid-engined (and weight distribution should be 50:50), plenty of the suspension parts are billet machined and the suspension wishbones are said to be ‘DTM-derived’. A host of parts are unique to this car. Plus, of course, the very best external suppliers have been used: Brembo iron or ceramic brakes, H&R anti-roll bars, Bosch ECU and so on.

Indeed, the Bosch relationship is worth delving into, because the Evo features both a bespoke ECU and its own ESP system. For a run of just 100 cars, remember. When HWA talks of ‘unprecedented engineering prowess’, it isn’t exaggerating. It’s easy to imagine a finely adjustable stability control system, too, one that will enable owners to get the most from their c. 500hp Evos on road or track. HWA’s CTO Gordian Von Schöning added: “It is unheard of for a bespoke, low volume manufacturer like HWA to partner with a top-tier OEM supplier like Bosch for such a limited production run. But when evaluating how to realise the full potential of the car, and do justice to the level of engineering that we have put into it, we concluded that going to such lengths was the only option we could fully endorse.” That’ll be the benefit of a working relationship stretching back a quarter of a century.

Unsurprisingly, then, almost all of the HWA Evos are spoken for. A few remain, however, for those who want to experience what a company that’s built some of the greatest Mercedes racers ever might do with a road car. It promises to be pretty spectacular.

Such a beautiful clean design. Was thinking a lightly modded and updated one of those would be a wonderful thing to own.

The Evo has always seemed a bit OTT to me. A bit too much going on.

Even a base model 190 on steel wheels and hub caps looks great.

Still think it's a great looking car and would be in my lottery garage for sure.

...when you're clearly a talented bunch of engineers and designers, why bother making something that looks a little like a 40 year old design that you've tried to update? Why not just style a new shell? Or develop a spaceframe that can accept a variety of body styles. Especially as, I assume, you have to refurbish the remaining W201 DNA to some extent anyway.

The problem with bespoke ecus and the like is that when they go wrong ( and they do ) it can be very difficult to find a replacement and without one, you are sitting on a non starter of a car.

...when you're clearly a talented bunch of engineers and designers, why bother making something that looks a little like a 40 year old design that you've tried to update? Why not just style a new shell? Or develop a spaceframe that can accept a variety of body styles. Especially as, I assume, you have to refurbish the remaining W201 DNA to some extent anyway.

It's also a bit of a myth that the 2.5 variant was a "lesser" engine in terms of Cosworth's involvement. The 2.5 cylinder head was an evolution of the earlier 2.3, including the addition of a double timing chain setup. The early 2.5 heads still carried the "Coscast" stamp though, and were still a Cosworth design, carrying the same "WAB" internal product code as the 2.3. The stamping was deleted later on down the line though, to spare Mercedes-Benz the indignity of having to broadcast that they relied on a British company to sort the job out!

The engines have different characteristics, the 2.3 being closer to the original brief of being used for rallying. The 2.5 was a bit less "frantic", smoother and more refined. Most people tend to prefer the 2.3, it's a bit like the difference between big and small turbo variants of the Escort Cosworth's YB engine, a lot of people prefer the lag and drama!

Gassing Station | General Gassing | Top of Page | What's New | My Stuff