Strengthening fibreglass doors.

Discussion

Does anyone have any good ideas how to strengthen 2 doors I’ve bought for my car?

I got them to save weight, they are only 5kg compared to my standard stripped doors weighing 17.5kg. But as you can imagine they are quite flimsy and I’d like to glue something lightweight into the door to give me a bit more crash protection.

I was thinking some repurposing sort of carbon fibre/fibreglass extrusion or something. In my original doors I glued in some aluminium box section from a roller door but that was quite heavy.

Any ideas?

I got them to save weight, they are only 5kg compared to my standard stripped doors weighing 17.5kg. But as you can imagine they are quite flimsy and I’d like to glue something lightweight into the door to give me a bit more crash protection.

I was thinking some repurposing sort of carbon fibre/fibreglass extrusion or something. In my original doors I glued in some aluminium box section from a roller door but that was quite heavy.

Any ideas?

If you want to stiffen the doors so they close better or don't flap around so much at speed, you could stiffen them quite a lot by adding fiberglass stiffeners as others have suggested. Neither the door nor any of these light weight stiffeners will give you the slightest protection in a crash. If you're after crash protection then you should be looking at side intrusion bars or air bags. Air bags are not usually a DIY option.

Any crash protection, anti-intrusion bars etc, would need to be stoutly attached to the rest of the car via the hinges and the door lock, otherwise it just means you get hit by the door rather than the car that hits it. I imagine that amount of steelwork would carry you towards the weight of the standard doors, if not over it.

Chris,

I can recommend paper honeycomb!

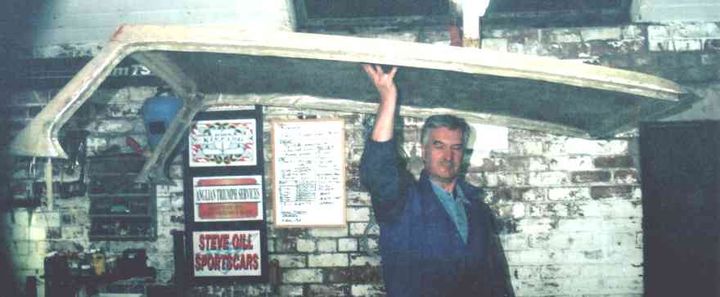

I bought some from Dufaylite ( https://dufaylite.com/) to build an esate roof and doors for racing Triumph Vitesse. The outer skin was made with half thickness random matt, I attached the honeycomb to that with polyurethane foam and then lined that with GRP tissue. The result was enormously stiff! And light - the roof weighed 9kgs when the original metal roof was 30kgs

The doors were made in a similar way, but with external and internal shells - I lined the external with honeycomb.

John

I can recommend paper honeycomb!

I bought some from Dufaylite ( https://dufaylite.com/) to build an esate roof and doors for racing Triumph Vitesse. The outer skin was made with half thickness random matt, I attached the honeycomb to that with polyurethane foam and then lined that with GRP tissue. The result was enormously stiff! And light - the roof weighed 9kgs when the original metal roof was 30kgs

The doors were made in a similar way, but with external and internal shells - I lined the external with honeycomb.

John

Edited by tapkaJohnD on Monday 21st July 18:28

Thebaggers said:

I have exactly the same challenge, my initial idea was to cut to internal width some plastic waste pipe and glass it is, firming the connection between both skins.

Will hopefully be on it soonish so can compare success notes!

With non-structural reinforcements like these, the ribs you add are just there as a form to build the fiberglass skin over. It's the fibreglass that gives it the stiffness. So don't use anything heavier than necessary, and make sure it's safe to use with your resin. (Some resin/plastic combinations react badly.)Will hopefully be on it soonish so can compare success notes!

If you're stiffening a panel formed by two skins then this works slightly differently. The honeycomb/foam/whatever filler you use is a loaded part of the structure and actually transfers the loads between the two skins. Here it needs to be stiff and strong, and preferably not absorb resin. Most places that sell fibreglass will also sell suitable foam, and you can even get it pre-cut so it can be curved.

Gassing Station | Home Mechanics | Top of Page | What's New | My Stuff