Making my own ramps

Discussion

Is there any guidance on how to calculate load capacity on steel fabrications? Rules of thumb, engineering calculators, the sort of thing?

I am thinking of creating two ramps, about 4 metres long. One end of each would hook over a supported beam at, say 1m High. The other ends would have a bar through them to 'lock' them together and a pair of high lift jack's to pump up the ramps to be level. I would also put in central supports, but these would go in after they were jacked up and level - so would just be for safety - the ramps need to be strong enough without them.

They would be for basic maintenance of cars - not professionally, just some home mechanics. They would also be relatively easy to store when not in use which is the drawback of the "showroom style ramps" that are like giant see-saws.

I tend to over engineer things- but will end up with a lot of extra weight to move about if I do my usual.

I am thinking of creating two ramps, about 4 metres long. One end of each would hook over a supported beam at, say 1m High. The other ends would have a bar through them to 'lock' them together and a pair of high lift jack's to pump up the ramps to be level. I would also put in central supports, but these would go in after they were jacked up and level - so would just be for safety - the ramps need to be strong enough without them.

They would be for basic maintenance of cars - not professionally, just some home mechanics. They would also be relatively easy to store when not in use which is the drawback of the "showroom style ramps" that are like giant see-saws.

I tend to over engineer things- but will end up with a lot of extra weight to move about if I do my usual.

McTrucky said:

Is there any guidance on how to calculate load capacity on steel fabrications? Rules of thumb, engineering calculators, the sort of thing?

I am thinking of creating two ramps, about 4 metres long. One end of each would hook over a supported beam at, say 1m High. The other ends would have a bar through them to 'lock' them together and a pair of high lift jack's to pump up the ramps to be level. I would also put in central supports, but these would go in after they were jacked up and level - so would just be for safety - the ramps need to be strong enough without them.

They would be for basic maintenance of cars - not professionally, just some home mechanics. They would also be relatively easy to store when not in use which is the drawback of the "showroom style ramps" that are like giant see-saws.

I tend to over engineer things- but will end up with a lot of extra weight to move about if I do my usual.

If you don’t know what you’re doing, then it’s probably best that you don’t build a ramp. Quick jack lift is the sort of thing that might suit you best.I am thinking of creating two ramps, about 4 metres long. One end of each would hook over a supported beam at, say 1m High. The other ends would have a bar through them to 'lock' them together and a pair of high lift jack's to pump up the ramps to be level. I would also put in central supports, but these would go in after they were jacked up and level - so would just be for safety - the ramps need to be strong enough without them.

They would be for basic maintenance of cars - not professionally, just some home mechanics. They would also be relatively easy to store when not in use which is the drawback of the "showroom style ramps" that are like giant see-saws.

I tend to over engineer things- but will end up with a lot of extra weight to move about if I do my usual.

There are techniques to calculate the strength and stiffness of a beam in bending. It's relatively easy to do for beams with a simple section such as square, rectangle, I-beam, and you'll probably find calculators online. Doing it for a non-standard non-uniform frame will be harder and probably more trouble than its worth. If you calculate how big an I beam would be needed to support a point load over that length and then use a similar quantity of metal with a similar depth then you probably won't be far off. You'd want a safety margin of 5-10 in any case so the answer doesn't need to be particularly accurate.

If you get an experienced fabricator to make it for you, they'll probably just eyeball it.

If you get an experienced fabricator to make it for you, they'll probably just eyeball it.

Thanks all,

Thought about the wood sleepers, been there and done that previously, but the height I want becomes a bit sketchy - and the lack of side access is not great.

Modifying a set of see saw ramps is definitely a possibility. Been keeping an eye on eBay for a local set for a while. But I do like fabricating things - which is part of the attraction of making rather than buying.

Thought about the wood sleepers, been there and done that previously, but the height I want becomes a bit sketchy - and the lack of side access is not great.

Modifying a set of see saw ramps is definitely a possibility. Been keeping an eye on eBay for a local set for a while. But I do like fabricating things - which is part of the attraction of making rather than buying.

HughG said:

From your description it needs to act as a simply supported beam, spanning from the top support to the jacking point, not just as a ramp with the strength to transfer the load to whatever it is sat on.

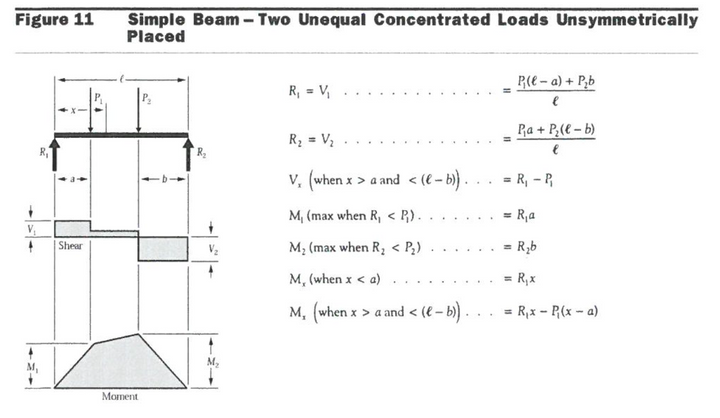

Have a look at this to work out the forces. I'd suggest a big factor of safety.

To me, it is much simpler.... Have a look at this to work out the forces. I'd suggest a big factor of safety.

If I want a capacity of 2.5T, that gives me a downward force of 25000 Newton's. Across two ramps, so 12500 each. I could assume all force is applied centrally (which it obviously is not, but would be worst case scenario).

i started typing out a response, but then after typing 'you die' so much, it became a bit morbid.

i'm with another poster - if you dont know what you're doing, i wouldnt attempt it. people suffer life changing injuries simply falling off ladders, let along having 2 tonne cars crushing them.

i'm with another poster - if you dont know what you're doing, i wouldnt attempt it. people suffer life changing injuries simply falling off ladders, let along having 2 tonne cars crushing them.

Go and have a look at 4 poster car lifts, the ramps you want to build are doing the same job as the wheel platforms of a lift so they need more or less the same strength and stiffness. What you're proposing to do is not very practical as the ramps will need lifting equipment to move them about due to weight and buying the materials will get you a long way toward the cost of buying a cheap lift from Automotech etc., never mind the implications of designing and building lifting equipment while not really grasping the rules for doing so safely.

Edited by hidetheelephants on Saturday 17th August 21:02

Once, I built my own car trailer. No calculations, no stress analysis, just built strong (2" square section tubes) and well braced.

It was a bit heavy, but did the job, never failed.

Weight will not be a problem for ramps, as long as you can drag them about, so follow the design of commercial ramps, use thicker tube and ensure your welding is fully penetrated.

John

It was a bit heavy, but did the job, never failed.

Weight will not be a problem for ramps, as long as you can drag them about, so follow the design of commercial ramps, use thicker tube and ensure your welding is fully penetrated.

John

Chris32345 said:

Ramps the raise a car 1m ????????

That's sounds like suicide

Why do you need such a height

Its not enough to walk under and you'd need much less then then to Kay under a car

1m is too high for laying down underneath and too low to stand under

You are right, 1m is an awkward height - it was just an example. The critical question is about the ramp strength - be they 2 inches, or 2 metres off the ground, the forces are the same. If I get to the design stage I guess I would be looking at 30cm to 40cm.That's sounds like suicide

Why do you need such a height

Its not enough to walk under and you'd need much less then then to Kay under a car

1m is too high for laying down underneath and too low to stand under

Cotty said:

What's wrong with the regular ramps you can get.

I have a set of these I don't want and can't even give them away, no one wants them.

With a sports car, you need an extender as they are too steep. Even with extenders, you can only lift one end of the car. Then the other end is then very low, usually too low to get a jack in there and raise that end. I use ramps a lot, but getting the car up and level is much more desirable. I have used planks and sleepers to raise the rear, then driven forward onto ramps, then trolley jacked the rear up and put blocks under the wheels, but it all gets very sketchy and is a pain to do and undo. I have a set of these I don't want and can't even give them away, no one wants them.

A pair of long ramps is an obvious solution, which is what I am aiming for. Drive up the ramp, then lift the lower end to level the car.

McTrucky said:

A pair of long ramps is an obvious solution, which is what I am aiming for. Drive up the ramp, then lift the lower end to level the car.

You can buy dealer display ramps which are essentially a see-saw which you drive up until the car is balanced and then rock it over. I don't know how expensive they are and I guess the heavy duty ones could get quite pricey, but the light weight ones don't look particularly complicated.GreenV8S said:

You can buy dealer display ramps which are essentially a see-saw which you drive up until the car is balanced and then rock it over. I don't know how expensive they are and I guess the heavy duty ones could get quite pricey, but the light weight ones don't look particularly complicated.

Yes. Seem to be £300 to £600 for second hand set - definitely an option.I had see-saw ramps, tilt lift thingies and now a mid-rise car lift.

See-saw ramps were great, but you will be limited on low cars both front and back due to the angle of attack. Not everyone likes driving up them as you wait for them to level out, either! Also bear in mind they are not really designed for removing wheels and doing brakes etc. You can still use a jack on them of course, but it's not ideal!

The tilt lift thingies (still have a set) are great. Just get a high torque drill to wind them up and down. You can also get a pivot point and just raise the rear or front of the car to a decent height. I used those for all sorts before my mid-rise.

Used the see-saws in a regular garage before our lockup. Ok if the vehicle wasn't very high.

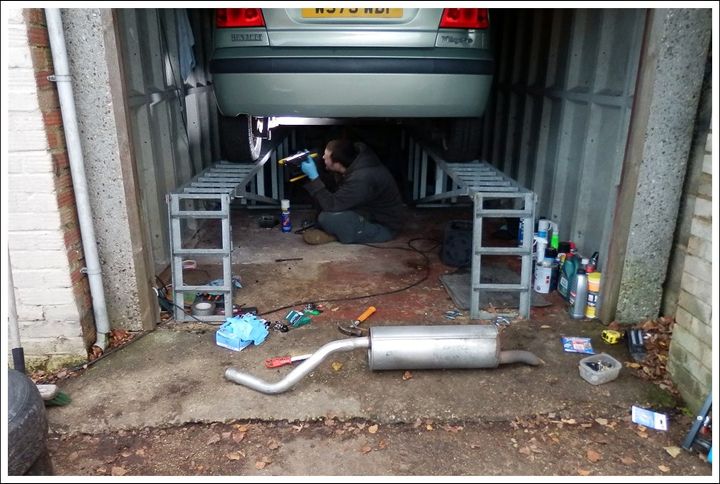

My friend also got some tilt lift things. Here's one of his previous cars lifted at the rear to give an example.

I now have these. They are also great for raising up and using as a workbench if you chuck a piece of wood across them.

As for costs, from memory, my first tilt lifts were second hand and around 250 quid, then I got a new set for around 450.

Had two sets of see-saws, both second hand. I also paid around 250 for both sets.

The mid-rise was also second hand but was being used at a car detailers, so was mint! I paid around 650 for that.

See-saw ramps were great, but you will be limited on low cars both front and back due to the angle of attack. Not everyone likes driving up them as you wait for them to level out, either! Also bear in mind they are not really designed for removing wheels and doing brakes etc. You can still use a jack on them of course, but it's not ideal!

The tilt lift thingies (still have a set) are great. Just get a high torque drill to wind them up and down. You can also get a pivot point and just raise the rear or front of the car to a decent height. I used those for all sorts before my mid-rise.

Used the see-saws in a regular garage before our lockup. Ok if the vehicle wasn't very high.

My friend also got some tilt lift things. Here's one of his previous cars lifted at the rear to give an example.

I now have these. They are also great for raising up and using as a workbench if you chuck a piece of wood across them.

As for costs, from memory, my first tilt lifts were second hand and around 250 quid, then I got a new set for around 450.

Had two sets of see-saws, both second hand. I also paid around 250 for both sets.

The mid-rise was also second hand but was being used at a car detailers, so was mint! I paid around 650 for that.

Gassing Station | Home Mechanics | Top of Page | What's New | My Stuff