Keeping track of nuts on bolts

Discussion

nuts and bolts *

As my DIYing gets more and more serious I'm finding myself not so confident in keeping track of nuts and bolts.

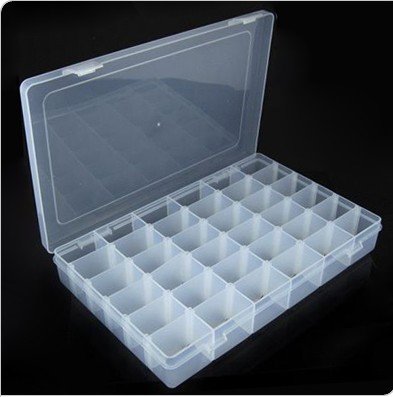

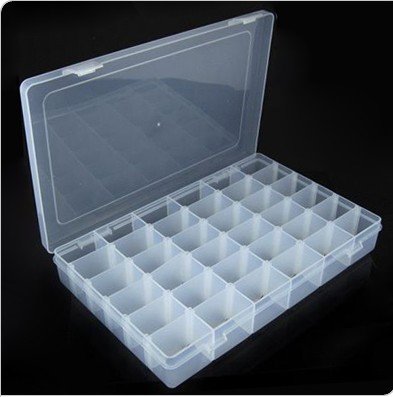

At the moment I use a combination of this:

And also keeping nuts and bolts with the parts that are coming off.

But I am still finding myself questioning myself and double guessing where the bolts came from, especially in the compartment version. Especially where I would be dropping a subframe and all of a sudden there will be something in the way so I will quickly remove a bolt and put in a compartment. It's this type of bolt that I'd forget where it'd come from.

How do you guys keep track of where the nuts and bolts came from?

As my DIYing gets more and more serious I'm finding myself not so confident in keeping track of nuts and bolts.

At the moment I use a combination of this:

And also keeping nuts and bolts with the parts that are coming off.

But I am still finding myself questioning myself and double guessing where the bolts came from, especially in the compartment version. Especially where I would be dropping a subframe and all of a sudden there will be something in the way so I will quickly remove a bolt and put in a compartment. It's this type of bolt that I'd forget where it'd come from.

How do you guys keep track of where the nuts and bolts came from?

Digital photos are a quick and easy way to keep track most phones have the capacity for this nowadays if you have any doubt before starting a job this can be invaluable.

I like to replace bolts loosely into their locations if possible or group them together with the various components such a s starter motor bolts with the starter you can even gaffer tape any fixings to the component if they are to be left dismantled for some time.

lastly larger bolts can be pushed through a cardboard template to keep them in order this works well with head bolts etc.

I like to replace bolts loosely into their locations if possible or group them together with the various components such a s starter motor bolts with the starter you can even gaffer tape any fixings to the component if they are to be left dismantled for some time.

lastly larger bolts can be pushed through a cardboard template to keep them in order this works well with head bolts etc.

I use a large divider box and just group the fasteners from one complete assembly in a box, e.g. all the bolts from the bellhousing, the bolts from the engine mounts etc...

Use of the Mk1 eyeball and a few brain cells then allows you to put them back where they came from, being careful of blind holes where there are multiple fastener lengths.

Use of the Mk1 eyeball and a few brain cells then allows you to put them back where they came from, being careful of blind holes where there are multiple fastener lengths.

Digital camera can be great! I tend to chuck them in a plastic box and go by common sense and memory in reassembly mode. I do remember overhauling a SAAB cylinder head and carefully keeping shims etc. carefully on a shoebox lid with holes then dropping the lot! The air was full of valves and springs and shims and collets - you can imagine the scene. Luckily I had a micrometer and lots of other bits so was able to replace some lost collets and sort out clearances.

As mentioned "Bolts in holes" is a good rule to follow. Works for 90% of jobs I do.

For longer complex jobs that won't be done in one hit, like if I'm doing a full engine rebuild over a few weekends, a cheap pack of envelopes and a shoe box does me well. Remove component, place fasteners in envelope, label, seal and put in box.

When you come to rebuild you just have to find and open the corresponding pack of bits. No problems, even if it's months later.

For longer complex jobs that won't be done in one hit, like if I'm doing a full engine rebuild over a few weekends, a cheap pack of envelopes and a shoe box does me well. Remove component, place fasteners in envelope, label, seal and put in box.

When you come to rebuild you just have to find and open the corresponding pack of bits. No problems, even if it's months later.

Edited by JordanTurbo on Saturday 14th February 22:33

If I've got a big job to do, with lots of sub assemblies, I will put all the nuts and bolts for that sub assembly in a little pot, with the assembly. I try and keep the bolts associated with the assembly as much as possible,and will try and put bolts in holes as much as possible.

Sometimes I'm lazy, and throw all the bolts into the top of my socket set - and that usually results in disaster when I accidentally kick the socket set or something stupid. I always try and put bolt packets next to a wall to avoid kicking the pot over as well.

I do quite a lot of kicking in my workshop

Sometimes I'm lazy, and throw all the bolts into the top of my socket set - and that usually results in disaster when I accidentally kick the socket set or something stupid. I always try and put bolt packets next to a wall to avoid kicking the pot over as well.

I do quite a lot of kicking in my workshop

Gassing Station | Home Mechanics | Top of Page | What's New | My Stuff