Any refrigeration engineers in?

Discussion

Had a 2nd hand walk in cold store installed (ex butcher shop, been in storage 1 year), all seemed to be working well until it got to temp, gassed down but the compressor keeps running and doesn't cut out.

The young lad the company sent to install it thinks LPS may be faulty, (is not adjustable) the part he pointed out has the following markings - on one side

20 NO 5

Danfoss

on the other

LCB-PC03

061F9010

Z 084 PL

Can't find the replacement part with google, presumably could just put in a generic or adjustable LPS?

The young lad the company sent to install it thinks LPS may be faulty, (is not adjustable) the part he pointed out has the following markings - on one side

20 NO 5

Danfoss

on the other

LCB-PC03

061F9010

Z 084 PL

Can't find the replacement part with google, presumably could just put in a generic or adjustable LPS?

Buzz84 said:

The low pressure switch is there as a safety to shut down the compressor to protect it from damage in the event of low gas due to a leak.

It's not used to control the system and cycle the compressor in normal day to day operation.

Refrigeration units are generally pretty dumb, they just run when told to cool.

Stuck relay/contactor? faulty or incorrectly set controller? Faulty thermocouple?

I know very little about these units, just going on what the lad who fitted it told me. A wiring error or faulty thermocouple would seem more likely as it was working fine when decommissioned and the LPS looks untouched / faily well protected being inside the unit.It's not used to control the system and cycle the compressor in normal day to day operation.

Refrigeration units are generally pretty dumb, they just run when told to cool.

Stuck relay/contactor? faulty or incorrectly set controller? Faulty thermocouple?

It has a danfoss controller which seems to be working fine otherwise - easy to set desired temp, and you can hear a relay click when it reaches 0.1 degrees below set temp. It then gasses down as it should, but the compressor continues to run. The lad thought that the LPS should stop the compressor when detected low pressure from gassing down, and went to adjust the it but realised that there was no adjustment...

The company was supposed to be getting back to me but I get the impression they are rather busy with much bigger jobs and not particularly interested. I'm struggling to get anyone out and would like to have the parts when they arrive.

LastPoster said:

What do you mean by ‘gassed down’?

Sorry, I'm not particularly familiar with these units, I think I probably mean pumped down. It was explained that when it reaches the set temperature, the units pumps all the gas out of the cooling system into a storage cylinder, the low pressure then triggers a switch that then turns off the compressor....The pumping down seems to work, only the compressor continues to run. Buzz84 said:

Thing is you haven't had a diagnosis that the LPS is at fault

If the "lad" thought it was the pressure switch then it would have been easy enough to confirm with a multimeter to see if it were switching based on pressures.

He could have also have put in a link or disconnected it to simulate operation.

Exactly, that is what I am thinking that it may not be the LPS that is faulty, and would like to try and figure out what the problem is so that I can order parts ready for when I can persuade someone to come out. I'm happy to put a multimeter on and look at the electric side but not happy to mess about with compressed gasIf the "lad" thought it was the pressure switch then it would have been easy enough to confirm with a multimeter to see if it were switching based on pressures.

He could have also have put in a link or disconnected it to simulate operation.

Buzz84 said:

Thing is you haven't had a diagnosis that the LPS is at fault

If the "lad" thought it was the pressure switch then it would have been easy enough to confirm with a multimeter to see if it were switching based on pressures.

He could have also have put in a link or disconnected it to simulate operation.

Many thanks for your input, yes I agree, would like to diagnose the problem. If I put up some photos would you be able to give me some pointers as to how to diagnose if it is the LPS or whatever you suggest?If the "lad" thought it was the pressure switch then it would have been easy enough to confirm with a multimeter to see if it were switching based on pressures.

He could have also have put in a link or disconnected it to simulate operation.

LastPoster said:

Being that you think the system worked correctly before it was moved then it may have been wired incorrectly which will be hard to diagnose

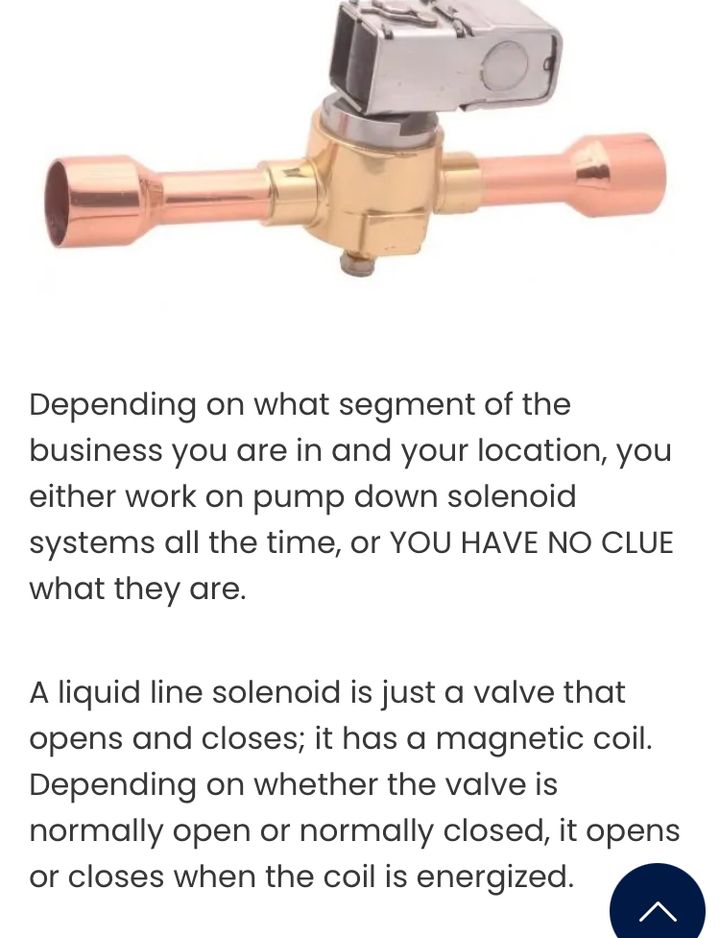

But, if it’s a system that pumps down (which would be very unusual in a small cold room system) then there will be a liquid line solenoid valve like this

When your controller indicates cooling is required, this valve will energise and open, gas will flow through the system, the Low Pressure control switch will close and the compressor start. Cooling will then begin. Once the required temperature is reached, the controller will de-energise the valve which will close. The compressor will suck all the liquid/gas out of the evaporator (cooling) coil and then shut down on the LP control and so on.

If this valve is not closing either due to a wiring issue or because it’s not closing correctly then the compressor won’t shut off. You will be able to tell if it’s energising or not at the right times by sticking a screwdriver on the top ( magnetised when energised). If there isn’t a valve like this it isn’t a pump down system

Is the cooling system actually working correctly other than the compressor not shutting off. If it is and the room isn’t getting too cold then the pump down solenoid is working ok.

In which case it’s again either wiring or the switch itself

You will need to know the pressure range of the existing switch and the refrigerant type to replace it

Thank you very much for taking the time to explain.But, if it’s a system that pumps down (which would be very unusual in a small cold room system) then there will be a liquid line solenoid valve like this

When your controller indicates cooling is required, this valve will energise and open, gas will flow through the system, the Low Pressure control switch will close and the compressor start. Cooling will then begin. Once the required temperature is reached, the controller will de-energise the valve which will close. The compressor will suck all the liquid/gas out of the evaporator (cooling) coil and then shut down on the LP control and so on.

If this valve is not closing either due to a wiring issue or because it’s not closing correctly then the compressor won’t shut off. You will be able to tell if it’s energising or not at the right times by sticking a screwdriver on the top ( magnetised when energised). If there isn’t a valve like this it isn’t a pump down system

Is the cooling system actually working correctly other than the compressor not shutting off. If it is and the room isn’t getting too cold then the pump down solenoid is working ok.

In which case it’s again either wiring or the switch itself

You will need to know the pressure range of the existing switch and the refrigerant type to replace it

Yes, it has one of these, a Danfoss EVR10, interestingly the lad "left the magnet on" when testing, and something to do with this melted, he happened to have an old one the same in the van and replaced the blue plastic cover on it... is this likely to be the culpret then?

LastPoster said:

Not really, you can replace the solenoid coil with a magnet to force the valve open for testing purposes. However if the coil (the blue bit) is energised and you remove it from the valve for too long it will melt as you guy now knows

Sounds like the solenoid is ok (electrically at least) so my remote diagnosis is wiring incorrect or LP switch incorrectly set or not working

There is another possibility, that the compressor is very worn and can’t pull the refrigerant pressure down enough but that’s not so likely

As before, is the system achieving the temperature you want and does it over cool due to the continual running of the compressor?

Yes, reaches temp quickly and then drops slightly below desired temp ( about a degree or so) then sits at that temperature with the compressor running. The sound of the compressor changes once the desired temp is reached and gets progressively more different until I freak out and cut the power for fear of knackering it - have managed about 2 mins before shutting off power. It doesn't sound like it's going to lunch itself immediately and my girlfriend wouldn't be able to hear the difference but it definitely has my mechanical sympathy...

Sounds like the solenoid is ok (electrically at least) so my remote diagnosis is wiring incorrect or LP switch incorrectly set or not working

There is another possibility, that the compressor is very worn and can’t pull the refrigerant pressure down enough but that’s not so likely

As before, is the system achieving the temperature you want and does it over cool due to the continual running of the compressor?

Thanks, very helpful, I'll take some pictures tomorrow and post them up.

I'm curious if we might just not be giving a tired compressor enough time to engage the LPS, the quality control sticker from the unit is from 2015, I have no idea how long they are likely to last, it was probably in constant use for about 6-7 years before sitting for a year. Brand names on it are GEA Searle, Trenton and Marston, most parts seem to be Danfoss.

I've attached the pictures that the lad sent me of the LPS

I'm curious if we might just not be giving a tired compressor enough time to engage the LPS, the quality control sticker from the unit is from 2015, I have no idea how long they are likely to last, it was probably in constant use for about 6-7 years before sitting for a year. Brand names on it are GEA Searle, Trenton and Marston, most parts seem to be Danfoss.

I've attached the pictures that the lad sent me of the LPS

Many thanks LastPoster for all your help, much appreciated.

Yes, it is more complicated than we need, it was an ebay job, local commercial tenant needed it gone quickly so was only £100 for the whole thing.

I will test the electrical side of things as suggested and check with the lad whether he adjusted the amount of refrigerant, could it potentially cause this issue if there is too much refrigerant in there?

Cheers, James

Yes, it is more complicated than we need, it was an ebay job, local commercial tenant needed it gone quickly so was only £100 for the whole thing.

I will test the electrical side of things as suggested and check with the lad whether he adjusted the amount of refrigerant, could it potentially cause this issue if there is too much refrigerant in there?

Cheers, James

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff