Wobbling kitchen tap, know what to do, can't access

Discussion

Hey folks, so I've got a kitchen tap that wobbles.

Having put this job off for quite some time, thinking it would be a nightmare, it IS a nightmare.

I seem to be able to see exactly what to do, but actually doing it is another matter.

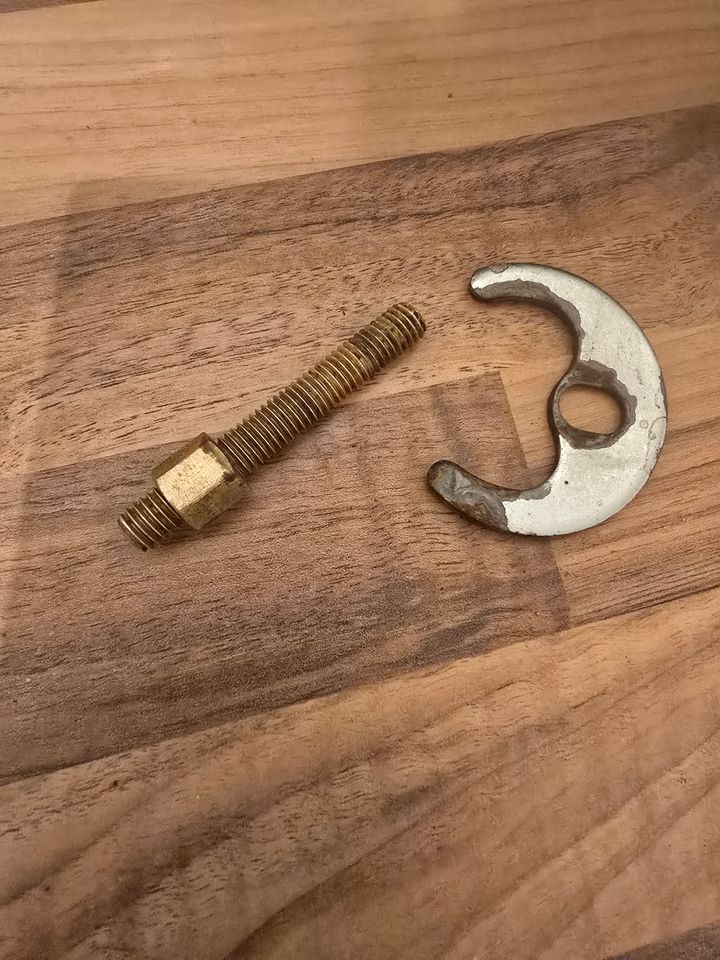

First off I found this fixing on the floor inside the cupboard, with the metal washer thing still just about hanging on for life around the pipes.

And this is the sight underneath the sink

Problem is I've got to work through the pipework which is making it nearly impossible to actually achieve. And I'm not a particularly small or flexible bloke, so getting my hands and arms in these gaps is proving extremely difficult.

I gather I should probably be able to screw in this thread first with a screwdriver, but it's impossible to get any screwdriver I own anywhere near it.

I've also tried with the washer and nut attached and using a tool out of my socket set but not only is it nearly impossible to access, but I can't actually see what I'm doing

I can't see any other way of fixing this other than pulling out all the pipes and then doing it?

If anyone has an alternative way of securing the tap that doesn't sacrifice my sanity then I'm all ears.

Cheers!

Having put this job off for quite some time, thinking it would be a nightmare, it IS a nightmare.

I seem to be able to see exactly what to do, but actually doing it is another matter.

First off I found this fixing on the floor inside the cupboard, with the metal washer thing still just about hanging on for life around the pipes.

And this is the sight underneath the sink

Problem is I've got to work through the pipework which is making it nearly impossible to actually achieve. And I'm not a particularly small or flexible bloke, so getting my hands and arms in these gaps is proving extremely difficult.

I gather I should probably be able to screw in this thread first with a screwdriver, but it's impossible to get any screwdriver I own anywhere near it.

I've also tried with the washer and nut attached and using a tool out of my socket set but not only is it nearly impossible to access, but I can't actually see what I'm doing

I can't see any other way of fixing this other than pulling out all the pipes and then doing it?

If anyone has an alternative way of securing the tap that doesn't sacrifice my sanity then I'm all ears.

Cheers!

You just need a monoblock tap spanner set.

You can probably pivk up a really long screw driver whilst you are at screwfix picking up the spanner set too.

https://www.screwfix.com/p/rothenberger-monoblock-...

You can probably pivk up a really long screw driver whilst you are at screwfix picking up the spanner set too.

https://www.screwfix.com/p/rothenberger-monoblock-...

A few options:

A really long screwdriver, rubber band on the head, squeeze the 'bolt' onto it and pray it goes it and you can turn it. (take the bolt and band to a DIY store/screwfix to test)

Disconnect the water (don't forget to turn it off first!), then get push fit flexihoses. Lift the tap from the top, fit the bolt and 'washer', feed it back through, tighten and then connect the flexi's to the water

Pay someone

SOMETHING like this: https://www.screwfix.com/p/jg-speedfit-monobloc-ta...

That may not be the right size, so double check!

A really long screwdriver, rubber band on the head, squeeze the 'bolt' onto it and pray it goes it and you can turn it. (take the bolt and band to a DIY store/screwfix to test)

Disconnect the water (don't forget to turn it off first!), then get push fit flexihoses. Lift the tap from the top, fit the bolt and 'washer', feed it back through, tighten and then connect the flexi's to the water

Pay someone

SOMETHING like this: https://www.screwfix.com/p/jg-speedfit-monobloc-ta...

That may not be the right size, so double check!

Had another go, I'm not getting anywhere near even with the Mrs help, I've got bruised ribs, cuts and bruises all over my arms and hands, am now in a foul mood, and I'm not sure buying a load of tools I'll never use again will help given how tight everything is (the pictures probably don't do it justice). So I'll probably just get a plumber out. Life is too short for this s t. Thanks anyway chaps.

t. Thanks anyway chaps.

t. Thanks anyway chaps.

t. Thanks anyway chaps.sherman said:

You just need a monoblock tap spanner set.

You can probably pivk up a really long screw driver whilst you are at screwfix picking up the spanner set too.

https://www.screwfix.com/p/rothenberger-monoblock-...

Stop pissing about and buy this as advised.You can probably pivk up a really long screw driver whilst you are at screwfix picking up the spanner set too.

https://www.screwfix.com/p/rothenberger-monoblock-...

It really is a quite simple job to remove the copper pipe that runs to the tap as the joints are push-fit (have a look on you tube how to disconnect them)

You should then be able to either pull the tap fully out or if you only disconnect the nearest pipe, gain enough space to screw the bolt in from underneath. Then use box spanner to fully tighten the nut

You should then be able to either pull the tap fully out or if you only disconnect the nearest pipe, gain enough space to screw the bolt in from underneath. Then use box spanner to fully tighten the nut

andyxxx said:

It really is a quite simple job to remove the copper pipe that runs to the tap as the joints are push-fit (have a look on you tube how to disconnect them)

You should then be able to either pull the tap fully out or if you only disconnect the nearest pipe, gain enough space to screw the bolt in from underneath. Then use box spanner to fully tighten the nut

What looks like lack of isolation valves would just make me go and buy more tools than the IKEA £5 "all the tools you need" set You should then be able to either pull the tap fully out or if you only disconnect the nearest pipe, gain enough space to screw the bolt in from underneath. Then use box spanner to fully tighten the nut

OP - Halfords do great socket sets. Buy a full on pro one (min 100 pieces), some tap spanners, a set of decent screwdrivers, set of pliers. And a hammer.

Fit a new tap which uses flexi tails, converting the copper to compression, or you can get JG Speedfit tails if needed.

It is a pain, especially at that location, other option is as mentioned you need tap spanners.

It’s obviously unthreaded itself, ideally you’d be able to pull the tap through but doubtful it’s possible with the copper tails on, in order to screw that threaded rod in.

I’d get a new tap and flexi tails, plus the tap spanner’s and you should be ok.

It is a pain, especially at that location, other option is as mentioned you need tap spanners.

It’s obviously unthreaded itself, ideally you’d be able to pull the tap through but doubtful it’s possible with the copper tails on, in order to screw that threaded rod in.

I’d get a new tap and flexi tails, plus the tap spanner’s and you should be ok.

Pheo said:

Fit a new tap which uses flexi tails, converting the copper to compression, or you can get JG Speedfit tails if needed.

It is a pain, especially at that location, other option is as mentioned you need tap spanners.

It’s obviously unthreaded itself, ideally you’d be able to pull the tap through but doubtful it’s possible with the copper tails on, in order to screw that threaded rod in.

I’d get a new tap and flexi tails, plus the tap spanner’s and you should be ok.

Do not listen to this. It is a pain, especially at that location, other option is as mentioned you need tap spanners.

It’s obviously unthreaded itself, ideally you’d be able to pull the tap through but doubtful it’s possible with the copper tails on, in order to screw that threaded rod in.

I’d get a new tap and flexi tails, plus the tap spanner’s and you should be ok.

No need to fit a new tap or new flexi tails.

No need to change any fittings

You do not need tap spanners for this job.

Look at photo 1. Once the push fit are undone the tap will clearly lift up through the aluminium with the 'tails' on and allow the bolt to be screwed back into the tap

andyxxx said:

Pheo said:

Fit a new tap which uses flexi tails, converting the copper to compression, or you can get JG Speedfit tails if needed.

It is a pain, especially at that location, other option is as mentioned you need tap spanners.

It’s obviously unthreaded itself, ideally you’d be able to pull the tap through but doubtful it’s possible with the copper tails on, in order to screw that threaded rod in.

I’d get a new tap and flexi tails, plus the tap spanner’s and you should be ok.

Do not listen to this. It is a pain, especially at that location, other option is as mentioned you need tap spanners.

It’s obviously unthreaded itself, ideally you’d be able to pull the tap through but doubtful it’s possible with the copper tails on, in order to screw that threaded rod in.

I’d get a new tap and flexi tails, plus the tap spanner’s and you should be ok.

No need to fit a new tap or new flexi tails.

No need to change any fittings

You do not need tap spanners for this job.

Look at photo 1. Once the push fit are undone the tap will clearly lift up through the aluminium with the 'tails' on and allow the bolt to be screwed back into the tap

10mm deep socket on a long extension bar.

That's how I did it.

Also; no need for a new tap, as mentioned by previous poster. New seating gasket would be nice though. And I'd fit flexies and quarter turn waterstops just to make life a bit easier.

It's not rocket science.

Less than 20 quid for bits and less than an hour including fag break.

Sake...

That's how I did it.

Also; no need for a new tap, as mentioned by previous poster. New seating gasket would be nice though. And I'd fit flexies and quarter turn waterstops just to make life a bit easier.

It's not rocket science.

Less than 20 quid for bits and less than an hour including fag break.

Sake...

sherman said:

andyxxx said:

Pheo said:

Fit a new tap which uses flexi tails, converting the copper to compression, or you can get JG Speedfit tails if needed.

It is a pain, especially at that location, other option is as mentioned you need tap spanners.

It’s obviously unthreaded itself, ideally you’d be able to pull the tap through but doubtful it’s possible with the copper tails on, in order to screw that threaded rod in.

I’d get a new tap and flexi tails, plus the tap spanner’s and you should be ok.

Do not listen to this. It is a pain, especially at that location, other option is as mentioned you need tap spanners.

It’s obviously unthreaded itself, ideally you’d be able to pull the tap through but doubtful it’s possible with the copper tails on, in order to screw that threaded rod in.

I’d get a new tap and flexi tails, plus the tap spanner’s and you should be ok.

No need to fit a new tap or new flexi tails.

No need to change any fittings

You do not need tap spanners for this job.

Look at photo 1. Once the push fit are undone the tap will clearly lift up through the aluminium with the 'tails' on and allow the bolt to be screwed back into the tap

https://www.screwfix.com/p/monument-tools-monobloc...

(Sorry - I hadn't realised they could also be called tap spanners)

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff