Lathe alignment issue

Discussion

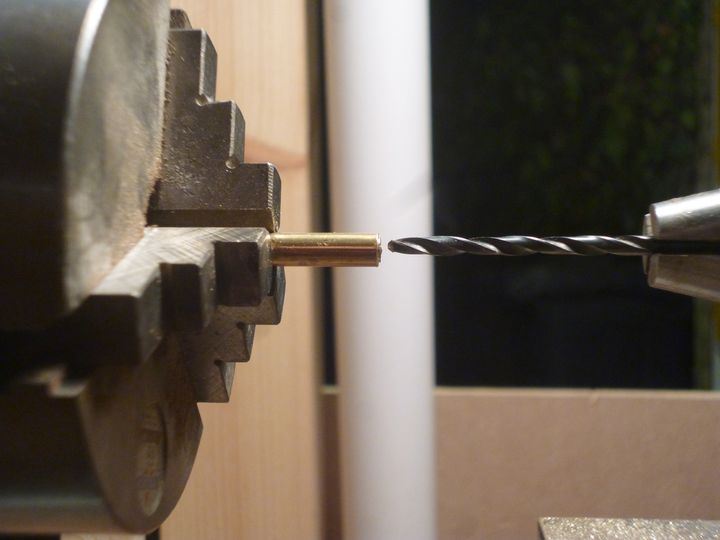

I couldn't understand why, when boring a hole in metal, the end of the drill skated around in circles, dangerously close to breaking, before going in. It wasn't the fore and aft alignment as I can adjust that when tightening the tailstock. But today I had a close look horizontally and saw this...

The drill bit is above the centre of the chuck!

The tailstock has no up/down adjustment so I can't understand why this is out of whack - unless the lathe bed is bent which seems unlikely. Any ideas on how to line things up?

The drill bit is above the centre of the chuck!

The tailstock has no up/down adjustment so I can't understand why this is out of whack - unless the lathe bed is bent which seems unlikely. Any ideas on how to line things up?

It's a Myford ML8 bought refurbished by from an eBay seller. It's possible the tailstock could be from a different lathe.

Can you enlighten me on 'running a DTI along the tailstock quill'?

(My wheeze of packing up the headstock lasted about one second as I realised the bed would go up too!)

Can you enlighten me on 'running a DTI along the tailstock quill'?

(My wheeze of packing up the headstock lasted about one second as I realised the bed would go up too!)

Extend the tailstock quill as far as you can without it actually falling out of the tailstock and lock both the tailstock and quill in position

Mount a dial test indicator on the bed of the lathe so it reads zero at one end of the quill and move the bed to run the DTI along the top of the quill to the other end, doesn't matter if you go front to back or back to front as you're looking for the variance.

It would only take a tiny bit of swarf trapped under the tailstock to tip it up at an angle and throw everything out of line

Mount a dial test indicator on the bed of the lathe so it reads zero at one end of the quill and move the bed to run the DTI along the top of the quill to the other end, doesn't matter if you go front to back or back to front as you're looking for the variance.

It would only take a tiny bit of swarf trapped under the tailstock to tip it up at an angle and throw everything out of line

Another way of checking is to mount a DTI in/on the chuck with the quill retracted as much as possible and rotate it around the quill see if the tailstock is concentric to the headstock both vertically and front to back, then move the tailstock back and extend the quill as far as possible and repeat.

If you get similar readings both times then everything is square but 'out' and if the readings vary then something else is 'out' if that makes sense?

ETA

Follow Easternlights advice above too, might be something bent with the drill/chuck/morse taper or a tiny bit of swarf on the taper.

We actually have a laser beam on one of our machines to check for this problem with every tool!!

If you get similar readings both times then everything is square but 'out' and if the readings vary then something else is 'out' if that makes sense?

ETA

Follow Easternlights advice above too, might be something bent with the drill/chuck/morse taper or a tiny bit of swarf on the taper.

We actually have a laser beam on one of our machines to check for this problem with every tool!!

Edited by Tango13 on Tuesday 24th December 18:22

Simpo Two said:

Thanks folks, I'll take a closer look tomorrow. No DTI though, it'll be a ruler!

Apologies...Tango13 said:

and move the bed to run the DTI along the top of the quill

Do you mean move the tailstock? The bed is fixed!I meant mount the DTI to the saddle and move the saddle along the bed to check the run out on the top of the tailstock quill.

A rule(r) of any type won't be anywhere near accurate enough though so you'll need to rummage down the back of the sofa and buy a DTI & stand

https://www.cromwell.co.uk/shop/measuring-and-test...

Cromwell stuff is usually good value for money

johnpsanderson said:

Are you sure the chuck is running true? Also, with a 3 jaw chuck I believe you’re not necessarily guaranteed the work piece will chuck up precisely, and it’s not necessarily replicable like a 4-jaw. All worth checking once you get the DTI I would think?

I have a 4-jaw chuck and getting things in the middle isn't something it naturally does! But I have used it to correct an eccentricity in wood turning after I lost the centre.Super Sonic said:

Is the tailstock chock on a morse taper? If so? Remove it and check the morse taper hole and shaft for dirt swarf etc.

Chock = chuck? Yes it is. I'll have a look soon. Everything seems to run true, just not quite joining in the middle!FYI here's an exploded diagram of the whole thing, just in case it throws up any clues:

AHH no dti. Can you make a pair of pointy cones? ('centres')

Put one in each chuck, retract the tail chuck into the tail stock and slide the tail stock towards the main chuck so the points almost touch, look at the height difference, then put the tailstock away from the main chuck, wind out the tailstock chuck till the centres almost touch, and compare the height difference. If it's the same in both cases, the tailstock and bed are parallel.

Check them for straightness with a ruler. Put a white piece of paper behind the bed and ruler to highlight any gaps. If both the tailstock and bad are straight and parallel and the tail chuck is still too high after all the above checks, it may, as suggested, be the wrong tailstock.

Put one in each chuck, retract the tail chuck into the tail stock and slide the tail stock towards the main chuck so the points almost touch, look at the height difference, then put the tailstock away from the main chuck, wind out the tailstock chuck till the centres almost touch, and compare the height difference. If it's the same in both cases, the tailstock and bed are parallel.

Check them for straightness with a ruler. Put a white piece of paper behind the bed and ruler to highlight any gaps. If both the tailstock and bad are straight and parallel and the tail chuck is still too high after all the above checks, it may, as suggested, be the wrong tailstock.

Rotate the 3 jaw chuck in the first photo 180 degrees and check the alignment again, if it's the same as in the photo the problem is with the tailstock end, if the alignment has changed the problem is with the 3 jaw chuck.

If it's the tailstock end you need to start by checking the bed is straight and then move onto the tailstock barrel, Jacobs chuck and then actual drill bit until you find the problem.

The ML8 is a wood turning lathe, it's not going to be as accurate or as rigid as a metal turning lathe. If you haven't leveled the lathe (wrong term really) and made sure there isn't a twist in the bed, you could introduce the problem above by adjusting the tailstock left to right to compensate for the twist.

If it's the tailstock end you need to start by checking the bed is straight and then move onto the tailstock barrel, Jacobs chuck and then actual drill bit until you find the problem.

The ML8 is a wood turning lathe, it's not going to be as accurate or as rigid as a metal turning lathe. If you haven't leveled the lathe (wrong term really) and made sure there isn't a twist in the bed, you could introduce the problem above by adjusting the tailstock left to right to compensate for the twist.

Gassing Station | Homes, Gardens and DIY | Top of Page | What's New | My Stuff