Looking for tiny custom-made brass fittings

Discussion

This may be one for railway modellers (ie people who build working model steam locos), I'm not sure.

I'm building a model a steam launch in 1:18 scale, and need various little brass fittings like handrail stanchions (there are none on the internet that look right) and then later, nuts about M1 size and a few other specific bits. The engine will be a dummy, but I want it to look as authentic as possible.

Are there any PHers who could assist please? (payment available)

I'm building a model a steam launch in 1:18 scale, and need various little brass fittings like handrail stanchions (there are none on the internet that look right) and then later, nuts about M1 size and a few other specific bits. The engine will be a dummy, but I want it to look as authentic as possible.

Are there any PHers who could assist please? (payment available)

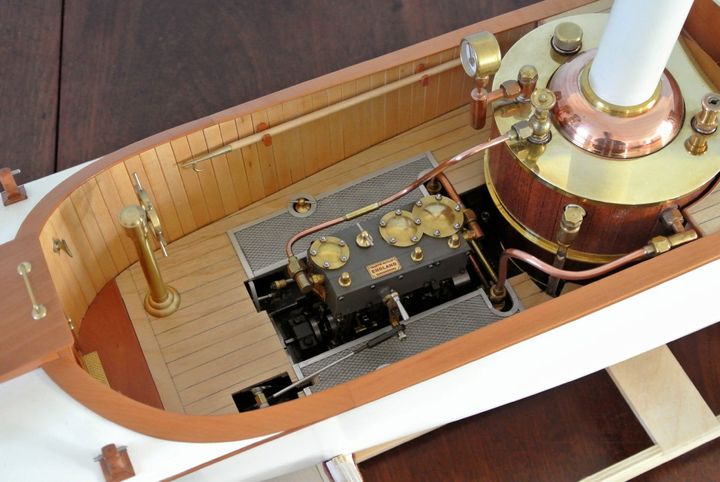

This is what I need to emulate. The wooden part of the boiler is already made and the engine block (black part) will be wood, it's all the twiddly fittings that are the challenge.

I can turn brass on a lathe but it's not my expertise; the parts that stump me most are the cylinder heads which are domed in the middle. But at least I'll have the little nuts to stick on them

The copper dome will be a challenge too, maybe my first go at metal spinning!

I can turn brass on a lathe but it's not my expertise; the parts that stump me most are the cylinder heads which are domed in the middle. But at least I'll have the little nuts to stick on them

The copper dome will be a challenge too, maybe my first go at metal spinning!

Simpo Two said:

Aha, the post next to mine might have the perfect chap for the job!

Unfortunately I’m still figuring out how to make several identical brass parts myself (oilers). Could be a ground ‘one-shot’ tool, but I hate making them. Could be co-ordinates and distances, which take forever.I made the domed cylinder ends on mine by calculating dozens of steps on CAD, feeding the lathe tool in to those points, then profiling the high spots with a file and abrasive paper until they were smooth.

dr_gn said:

I made the domed cylinder ends on mine by calculating dozens of steps on CAD, feeding the lathe tool in to those points, then profiling the high spots with a file and abrasive paper until they were smooth.

Thanks for checking in :-)I'd hoped that one could just draw a diagram on a bit of paper, scan it in to CAD software, then plug in the lathe and hit 'Go'.

The Dremel is an interesting idea; it adds a manual element a little bit like wood turning (which I do know about).

dr_gn said:

If it’s just for show, it would be way easier to print the whole thing in resin and spray the ‘metal’ bits with Alclad, or use bare metal foil.

I could turn them in wood easily, it's just a shame that metal turning works completely differently; you can't handhold the cutter or do curves.So, if I turned them from, say, a resin block, would 'bare metal foil' make them look like brass, or a bodge?

Simpo Two said:

I could turn them in wood easily, it's just a shame that metal turning works completely differently; you can't handhold the cutter or do curves.

So, if I turned them from, say, a resin block, would 'bare metal foil' make them look like brass, or a bodge?

Traditional watchmaker's lathes turn metal in the same way as wood is turned, although I'd not want to try steel doing objects in brass is worth a try.So, if I turned them from, say, a resin block, would 'bare metal foil' make them look like brass, or a bodge?

hidetheelephants said:

Traditional watchmaker's lathes turn metal in the same way as wood is turned, although I'd not want to try steel doing objects in brass is worth a try.

Interesting. What type of cutting tool do they use?I only need to do brass, though I'll need to make sure I've got the annealing process right so it's cuttable.

Simpo Two said:

dr_gn said:

I made the domed cylinder ends on mine by calculating dozens of steps on CAD, feeding the lathe tool in to those points, then profiling the high spots with a file and abrasive paper until they were smooth.

Thanks for checking in :-)I'd hoped that one could just draw a diagram on a bit of paper, scan it in to CAD software, then plug in the lathe and hit 'Go'.

The Dremel is an interesting idea; it adds a manual element a little bit like wood turning (which I do know about).

dr_gn said:

If it’s just for show, it would be way easier to print the whole thing in resin and spray the ‘metal’ bits with Alclad, or use bare metal foil.

I could turn them in wood easily, it's just a shame that metal turning works completely differently; you can't handhold the cutter or do curves.So, if I turned them from, say, a resin block, would 'bare metal foil' make them look like brass, or a bodge?

If you (or someone you knew) had a CNC lathe, then it's a lot simpler to make a batch of these items. As with anything like this though, it might seem dead easy to hit "go", but first, you need skills in CNC programming, and also knowledge of the best way to turn and drill the part. Workholding and fixturing is also a consideration becasue you can't necessarily just stick some material in a chuck and the part magically gets machined with no further hassle.

It's like 3D printing for scale models: some people say it's "cheating", but they rarely consider that you also need CAD skills and knowledge of design for manufacture to end up with the parts. Just becasue they aren't traditional skills doesn't make them any less relevant.

I don't have the experience to advise really. I am wanting to make about 10-off of these brass oilers (mine's the one on the left, on the right is a commercially available version, but too big):

Making one is easy. Making 10 identical is not.

I think the best way forward would be to join the Model Engineer forum, and ask there under "Workshop Techniques". The people on there are very experienced, and will give you all options for the equipment you've got, possibly up to and including someone offering to make the parts for you. Without that forum, I wouldn't have been able to make my first steam engine, at least not in the time it took me and I doubt it would have run as well as it does. The ongoing advice on all aspects of building my current engine (which is much more complicated)...money can't buy it.

hidetheelephants said:

No idea, but I imagine they work in much the same way as they use tool rests which look very much like those on wood lathes.

Genius! Look here:https://youtu.be/gK-5s5jAg0c?si=Ox1RuqiMOb9uQU5o&a...

I tried it briefly on my lathe with a metal-cutting bit but it felt wrong (bit too short) so I stopped.

I think I just need some of the tools/cutters/chisels and have a go... woodturning tools will be too soft and metal-cutting tools are too short to control.

dr_gn said:

I think the best way forward would be to join the Model Engineer forum, and ask there under "Workshop Techniques". The people on there are very experienced, and will give you all options for the equipment you've got, possibly up to and including someone offering to make the parts for you. Without that forum, I wouldn't have been able to make my first steam engine, at least not in the time it took me and I doubt it would have run as well as it does. The ongoing advice on all aspects of building my current engine (which is much more complicated)...money can't buy it.

My cunning plan - to send a fiver in a grubby envelope to Doc Green - has fallen through but been replaced by an even more cunning one... namely to abandon 'tech' and go in by hand.That's the thing I love about scratchbuilding - you have to figure it out yourself. It's also the thing I hate about scratchbuilding!

And here they are - called gravers:

https://bettsmetalsales.com/search/?q=graver

A whole new world appears... oooo...

https://bettsmetalsales.com/search/?q=graver

A whole new world appears... oooo...

You'll have to experiment to get the tool geometry right, what works for ordinary metal turning is unlikely to be optimum for hand turning. Brass can be grabby so maybe zero rake and not much relief will be the order of the day, it may even be beneficial to try a slightly blunt tool.

Gassing Station | Scale Models | Top of Page | What's New | My Stuff