TVR Craft Con Rods and Pistons

Discussion

I popped into see the guys at TVR Craft today to catch up with progress on my car and to have a look at the new con rods that have just arrived from Carrillo.

The first surprise was to see that they have taken another unit, and doubled their workshop space. I missed the usual impressive line of “work in progress” Tuscans and Cerberas parked out front, but good to see all the customers cars are now tucked up under covers in a nice warm workshop !

The new con rods look great ! They are forged from Carrilloy (a proprietary alloy of chromium, nickel, vanadium and molybdenum) and are almost 20 % lighter than the standard rod whilst being 60% stronger and better balanced. The big end bolts are equally impressive – being 285,000 SPS Formula 3000 standard (I have no idea what this means - but was assured that it is "a good thing" ).

It is a bit of a shock to see the difference when comparing the two side by side (especially the extra mass in the little end of the TVR con rod).

The improved balance and lighter weight of the rods should mean that we can loose even more mass when the crank, pistons and new rods are balanced next week. Hopefully this will also allow the big hydraulic damper on the front of the crank to be ditched - further reducing stress and helping the engine to rev faster !

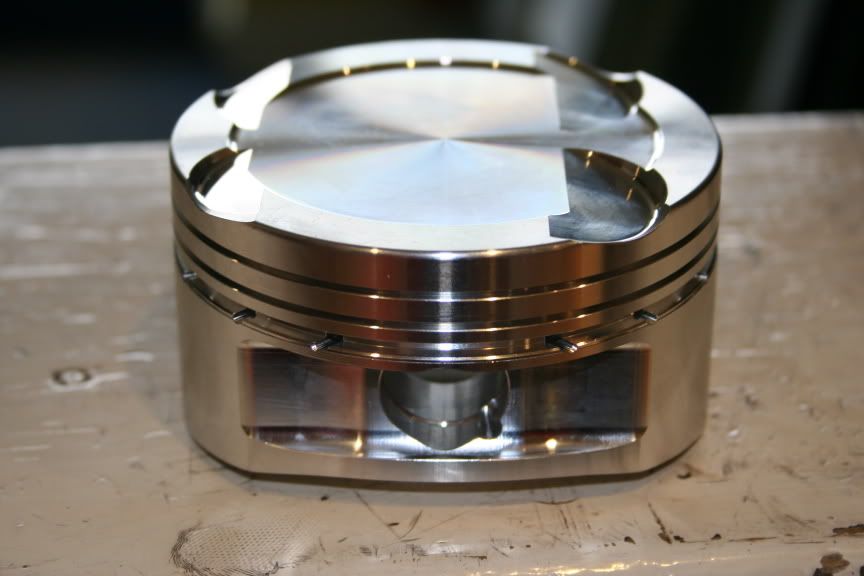

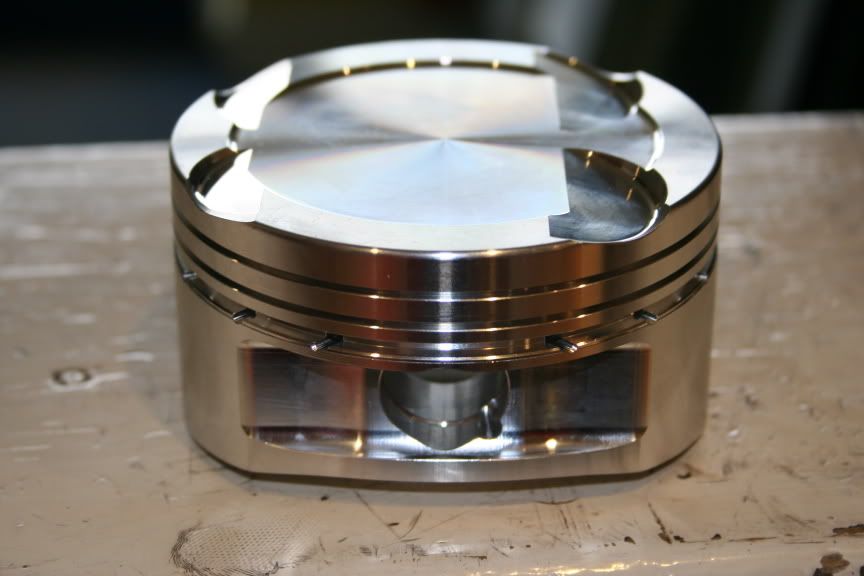

The new rods can be used with the standard pistons, or with the new TVR Craft pistons that have just arrived from JE (the ‘craft pistons are interchangeable and can also be used on the standard ‘rods).

These are also significantly lighter and use the same size rings as the standard piston (which they will supply separately if needed as apparently TVR won’t supply piston rings … ) .

If all goes according to plan the engine should be back together and running in the car in about 3 weeks. I can’t wait !

Cheers

Ian

>> Edited by red rose on Saturday 18th February 18:02

>> Edited by red rose on Saturday 18th February 18:03

The first surprise was to see that they have taken another unit, and doubled their workshop space. I missed the usual impressive line of “work in progress” Tuscans and Cerberas parked out front, but good to see all the customers cars are now tucked up under covers in a nice warm workshop !

The new con rods look great ! They are forged from Carrilloy (a proprietary alloy of chromium, nickel, vanadium and molybdenum) and are almost 20 % lighter than the standard rod whilst being 60% stronger and better balanced. The big end bolts are equally impressive – being 285,000 SPS Formula 3000 standard (I have no idea what this means - but was assured that it is "a good thing" ).

It is a bit of a shock to see the difference when comparing the two side by side (especially the extra mass in the little end of the TVR con rod).

The improved balance and lighter weight of the rods should mean that we can loose even more mass when the crank, pistons and new rods are balanced next week. Hopefully this will also allow the big hydraulic damper on the front of the crank to be ditched - further reducing stress and helping the engine to rev faster !

The new rods can be used with the standard pistons, or with the new TVR Craft pistons that have just arrived from JE (the ‘craft pistons are interchangeable and can also be used on the standard ‘rods).

These are also significantly lighter and use the same size rings as the standard piston (which they will supply separately if needed as apparently TVR won’t supply piston rings … ) .

If all goes according to plan the engine should be back together and running in the car in about 3 weeks. I can’t wait !

Cheers

Ian

>> Edited by red rose on Saturday 18th February 18:02

>> Edited by red rose on Saturday 18th February 18:03

Good read Ian!

Might I add, those rods were SPECIFICALLY designed by the boys at Craft for the Speed 6 engine and can be used in a stock speed 6 engine as they are designed to be direct relacements, but what a replacement!

Also with tvrcraft balancing the whole reciprocating mass through-out the WHOLE rev-range and keeping those harmonics at bay the damper can be ditched. The damper is also an after-thought, in the original design there was no need for a damper.

With all of this, your engine will not only run smoother but it will be seriously ALIVE! The reduction of a serious-amount of mass from that rotating assembly will greatly reduce the loading, possibly bring it right down to 2tonne per cyl, not sure exactly how much, would have to ask Dave.

Just to let all know, NO ONE else is doing this currently, the only way you know you are getting an exceptionally balanced engine is by the removal of that damper, which obviously is not required if everything else is balanced to exacting specification! For this reason, an engine builder has to go back to original spec and not the current production blueprint, which Craft are the only ones who have a license to do so (contractual agreement with Al Melling who still owns the rights to the original specification as it was never sold! those who went to the talk would remember this!)

Goodluck Ian, its been a good long wait, but it'll be over soon, so keep the fingers rolling!

and if you think the new speed 6 rods are something - you aint seen nothing yet! Wait till you see my rods destined for the phoenix!!!!!

Might I add, those rods were SPECIFICALLY designed by the boys at Craft for the Speed 6 engine and can be used in a stock speed 6 engine as they are designed to be direct relacements, but what a replacement!

Also with tvrcraft balancing the whole reciprocating mass through-out the WHOLE rev-range and keeping those harmonics at bay the damper can be ditched. The damper is also an after-thought, in the original design there was no need for a damper.

With all of this, your engine will not only run smoother but it will be seriously ALIVE! The reduction of a serious-amount of mass from that rotating assembly will greatly reduce the loading, possibly bring it right down to 2tonne per cyl, not sure exactly how much, would have to ask Dave.

Just to let all know, NO ONE else is doing this currently, the only way you know you are getting an exceptionally balanced engine is by the removal of that damper, which obviously is not required if everything else is balanced to exacting specification! For this reason, an engine builder has to go back to original spec and not the current production blueprint, which Craft are the only ones who have a license to do so (contractual agreement with Al Melling who still owns the rights to the original specification as it was never sold! those who went to the talk would remember this!)

Goodluck Ian, its been a good long wait, but it'll be over soon, so keep the fingers rolling!

and if you think the new speed 6 rods are something - you aint seen nothing yet! Wait till you see my rods destined for the phoenix!!!!!

AWESOME Ian truely awesome........You gotta post on here your impressions when you do get your motor back. You started off with just the top end fix and did a number of miles with that, I am really keen to hear your thoughts on comparing it to the full top and bottom solution.

Boys and Girls you have seen it and read it here......TVRCraft are the daddies for a real S6 solution. If the damper is left behind the solution is limited.

Ian..... happy motoring.....

Boys and Girls you have seen it and read it here......TVRCraft are the daddies for a real S6 solution. If the damper is left behind the solution is limited.

Ian..... happy motoring.....

I apologise if I'm teaching people to suck eggs here but I really think I need to say something about this because if I read this correctly this could be a potentially expensive even dangerous exercise.

The hydraulic damper on the front of the crankshaft does not balance the engine and must not be removed. The hydraulic damper is there to damp the torsional vibration of the crankshaft. Without it the crankshaft will go into a very large amplitude resonance at particular engine speeds (3rd, 6th, 9th dominant orders in 6 cylinders) and eventually break the crankshaft or the front pulley or even snap the crank palm & flywheel .

Engine oscillating/reciprocating balance is a different thing entirely. Reciprocating mass is the piston assembly, gudgeon pin, and roughly a third of the conrod mass. A 4-stroke 6 cylinder inline engines with the crankpins at 120degs will be inherently have reciprocating balance in the 1st and 2nd order forces and moments. Thats why 6 cyls are so smooth and many a german engineer will tell you it is the perfect engine config. Here is an excerpt from the Bosch Automotive Handbook (the inline 6 is in the bottom left hand corner):

The engine rotating mass is the crankshaft itself, the remaining 2/3rds of the conrods, flywheel and pulley. The balance weights on the crankshaft are there to balance each of the opposing crankpin and 2/3rds conrod mass. This means there will be no extra moments (and hence forces) acting on the main bearings.

Back onto torsional vibration of the crankshaft and as stated earlier the crankshaft damper-absorber is to take out the large amplitudes of crankshaft torsional vibration. The natural frequency of the crankshaft system is a function of crankshaft length, crankshaft torsional stiffness, crankshaft stroke, and the moments of inertia of rotating masses attached the crank. A crank harmonic balancer is an vibration absorber that the rubber & inertia ring matches the resonant frequencies of the crankshaft & rotating components and takes the dangerous amplitudes out and releases it as heat. The key is knowing where that worst frequencies are and without all the data and FE models of crankshaft to determine stiffness it is very difficult to calculate. Even then you need to tune it finally on a fully instrumented dyno. If you cannot easily determine those then you use a hydraulic (or viscous) crankshaft damper instead, which has happened here. This gives the luxury of damping over any engine speed and as long as the damper can dissipate the vibration energy it shouldn't be a problem. If you want read more on this I've put up an SAE paper on webspace here on pages 50-57. The paper is on diesel engine design but the physics are the same just the numbers are different.

I apologise if this sounds uppity but I've been in engine design for nearly 9 years now and have directly designed cranks, rods, pistons, blocks, heads, flywheels, oil & water pumps, chain drives and others. I'm sure i'm right and if you ask the Al Melling I'm pretty certain he will say exactly the same too, in fact I work with one of his MCD proteges!

All the best

Phil

PS those are some excellent looking rods and pistons there!

>> Edited by wheeljack888 on Sunday 19th February 12:22

The hydraulic damper on the front of the crankshaft does not balance the engine and must not be removed. The hydraulic damper is there to damp the torsional vibration of the crankshaft. Without it the crankshaft will go into a very large amplitude resonance at particular engine speeds (3rd, 6th, 9th dominant orders in 6 cylinders) and eventually break the crankshaft or the front pulley or even snap the crank palm & flywheel .

Engine oscillating/reciprocating balance is a different thing entirely. Reciprocating mass is the piston assembly, gudgeon pin, and roughly a third of the conrod mass. A 4-stroke 6 cylinder inline engines with the crankpins at 120degs will be inherently have reciprocating balance in the 1st and 2nd order forces and moments. Thats why 6 cyls are so smooth and many a german engineer will tell you it is the perfect engine config. Here is an excerpt from the Bosch Automotive Handbook (the inline 6 is in the bottom left hand corner):

The engine rotating mass is the crankshaft itself, the remaining 2/3rds of the conrods, flywheel and pulley. The balance weights on the crankshaft are there to balance each of the opposing crankpin and 2/3rds conrod mass. This means there will be no extra moments (and hence forces) acting on the main bearings.

Back onto torsional vibration of the crankshaft and as stated earlier the crankshaft damper-absorber is to take out the large amplitudes of crankshaft torsional vibration. The natural frequency of the crankshaft system is a function of crankshaft length, crankshaft torsional stiffness, crankshaft stroke, and the moments of inertia of rotating masses attached the crank. A crank harmonic balancer is an vibration absorber that the rubber & inertia ring matches the resonant frequencies of the crankshaft & rotating components and takes the dangerous amplitudes out and releases it as heat. The key is knowing where that worst frequencies are and without all the data and FE models of crankshaft to determine stiffness it is very difficult to calculate. Even then you need to tune it finally on a fully instrumented dyno. If you cannot easily determine those then you use a hydraulic (or viscous) crankshaft damper instead, which has happened here. This gives the luxury of damping over any engine speed and as long as the damper can dissipate the vibration energy it shouldn't be a problem. If you want read more on this I've put up an SAE paper on webspace here on pages 50-57. The paper is on diesel engine design but the physics are the same just the numbers are different.

I apologise if this sounds uppity but I've been in engine design for nearly 9 years now and have directly designed cranks, rods, pistons, blocks, heads, flywheels, oil & water pumps, chain drives and others. I'm sure i'm right and if you ask the Al Melling I'm pretty certain he will say exactly the same too, in fact I work with one of his MCD proteges!

All the best

Phil

PS those are some excellent looking rods and pistons there!

>> Edited by wheeljack888 on Sunday 19th February 12:22

Hi Phil,

Thanks for your input … very interesting stuff.

I’m not an engineer, so apologies to all if I have misunderstood what Dave at TVR Craft explained.

As I understand the original Speed 6 engine (as designed by Al Melling) did not use a crankshaft damper. This was added to the TVR version of the engine, as the TVR cast crank, heavier differently balanced con rods and heavier pistons behaved differently to the original.

I didn’t explain in the post above that my car has an MCD billet crank, rather than the standard cast item, and with the new con rods it will be similar in design to the original – and should therefore not need the damper.

Of course Al Melling is involved with all the TVR Craft modifications and is effectively “consultant engineer” to ‘Craft - so the final decision to run with or without the crank damper will only be made after his approval !

I’ll let you know how things progress.

Cheers

Ian

PS I agree, the con rods look great – almost a waste to hide them away !

Thanks for your input … very interesting stuff.

I’m not an engineer, so apologies to all if I have misunderstood what Dave at TVR Craft explained.

As I understand the original Speed 6 engine (as designed by Al Melling) did not use a crankshaft damper. This was added to the TVR version of the engine, as the TVR cast crank, heavier differently balanced con rods and heavier pistons behaved differently to the original.

I didn’t explain in the post above that my car has an MCD billet crank, rather than the standard cast item, and with the new con rods it will be similar in design to the original – and should therefore not need the damper.

Of course Al Melling is involved with all the TVR Craft modifications and is effectively “consultant engineer” to ‘Craft - so the final decision to run with or without the crank damper will only be made after his approval !

I’ll let you know how things progress.

Cheers

Ian

PS I agree, the con rods look great – almost a waste to hide them away !

Hi Ian

Good to hear that Al Melling is involved aswell. Hope it all comes together soon.

Just to add a billet steel crank is usually 10-20% stiffer but can be 10% heavier than a sg cast iron crank of same dimensions. Where the steel (depending on alloy/treatment) really wins is in its ability to take punishment (high yield strength). What the crank damper does is reduce the punishment. Inline 6 are long engines and hence suffer more from crank torsional vibration than other configurations, I'm pretty certain Melling wouldn't have run his initial engines without a damper. I could be wrong though!

Cheers

Phil

Good to hear that Al Melling is involved aswell. Hope it all comes together soon.

Just to add a billet steel crank is usually 10-20% stiffer but can be 10% heavier than a sg cast iron crank of same dimensions. Where the steel (depending on alloy/treatment) really wins is in its ability to take punishment (high yield strength). What the crank damper does is reduce the punishment. Inline 6 are long engines and hence suffer more from crank torsional vibration than other configurations, I'm pretty certain Melling wouldn't have run his initial engines without a damper. I could be wrong though!

Cheers

Phil

wheeljack888 said:

Hi Ian

Good to hear that Al Melling is involved aswell. Hope it all comes together soon.

Just to add a billet steel crank is usually 10-20% stiffer but can be 10% heavier than a sg cast iron crank of same dimensions. Where the steel (depending on alloy/treatment) really wins is in its ability to take punishment (high yield strength). What the crank damper does is reduce the punishment. Inline 6 are long engines and hence suffer more from crank torsional vibration than other configurations, I'm pretty certain Melling wouldn't have run his initial engines without a damper. I could be wrong though!

Cheers

Phil

I'm pretty sure I heard the original design did not require a damper, because of the way the bottom end was designed? also do take note the original design did take into account a billet crank and lots of high quality bits and bobs which didnt all make it into production engines.

Anyway, as far as an inline 6-cylinder design goes, yes there is both primary and secondary balance. Primary balance is when the crankshaft counterweights offset the weight of the piston and rod. Secondary balance is when the movement of one piston balances the movement of another. V6's have a secondary imbalance that causes engine vibration. Obviously adding a counter balance shaft can reduce this imbalance, but that adds weight and complexity.

Its well known there are difficulties in designing a good performing inline 6-cylinder. Its known the length of the engine allows more harmful torsional twist in the crankshaft, and makes cooling all the cylinders evenly more difficult. Stiffening the crankshaft does help reduce torsional twist (whence an EN40B crank) and usually a three part front crankshaft damper helps control twisting forces, obviously.

But...

There is more to the speed 6 engine than meets the eye, I guess Al Melling and Craft know something we dont?

Would be great if they joined in with these discussions, I definitely aint no engineer, just pass on a summary of what makes it into my head without the techy-gore...

All engines benefit from a torsional damper, a slight clue is that my 4 cylinder '96 Ford mondeo has one fitted.......

To an engine config which doesn't 'need' one from one of the most cost concious manufacturers out there.

Minimising torsional vibration is benficial to not just crankshaft and timing chain life but also allows the use of hairy cam profiles so more performance and higher revs becomes available

Matt

To an engine config which doesn't 'need' one from one of the most cost concious manufacturers out there.

Minimising torsional vibration is benficial to not just crankshaft and timing chain life but also allows the use of hairy cam profiles so more performance and higher revs becomes available

Matt

GreenV8S said:

I suspect there's a significant difference though, between using a harmonic torsional damper to damp out crank flex, versus using the front pulley as a counterweight to correct for an inherent dynamic imbalance .

I doubt the front pulley/damper is balancing anything else but itself. Only cruciform V8s that are not internally balanced use external counterweights on the crankpulley and flywheel (1st order reciprocating moment on V8s from scan above). Reciprocating balance is inherent on I-6 cyls so long as all the piston and rod masses are the same. The rotating balance of the crankshaft system (i.e. making sure the system centre of gravity is on the crank centreline) is only achieved by the crankwebs between each main bearing.

wheeljack888 said:

I suspect there's a significant difference though, between using a harmonic torsional damper to damp out crank flex, versus using the front pulley as a counterweight to correct for an inherent dynamic imbalance .

I doubt the front pulley/damper is balancing anything else but itself. Only cruciform V8s that are not internally balanced use external counterweights on the crankpulley and flywheel (1st order reciprocating moment on V8s from scan above). Reciprocating balance is inherent on I-6 cyls so long as all the piston and rod masses are the same. The rotating balance of the crankshaft system (i.e. making sure the system centre of gravity is on the crank centreline) is only achieved by the crankwebs between each main bearing.

The speed 6 main-bearings love to go for a walk! and they're only held in using bloody dowel pins (I think I got the jargon right)!!!! its amazing the whole assembly stays put, even with a damper forget about without!

WheelJack with 9 years behind you as an engineer, if you get a chance, ring Dave up to find out more on 01722 411 118.

I have a feeling he might not be too forthcoming though, as there have been a number of occasions where people have rung-up and spend hours on the phone picking his brains to only take the accumulated info elsewhere!!!! what a nice world hey! NOT!

I'll try and get some more info on this from Dave tomorrow, it is an interesting subject indeed! But it could prove difficult finding out more if its giving away any design secrets. I guess only days to go before Ian's engine is put together now and then we'll know a bit more...

>> Edited by SXS on Sunday 19th February 22:07

Just thought I'd let all know, theres more high-quality pics of the rods and pistons and stuff on crafts website:

www.tvrcraft.com

And they've started an online catalogue of components!

Hope it grows well and also hope they get some good V8 gear as well as SP6 gear in the list.

www.tvrcraft.com

And they've started an online catalogue of components!

Hope it grows well and also hope they get some good V8 gear as well as SP6 gear in the list.

Gassing Station | Speed Six Engine | Top of Page | What's New | My Stuff